What is Fulfillment?

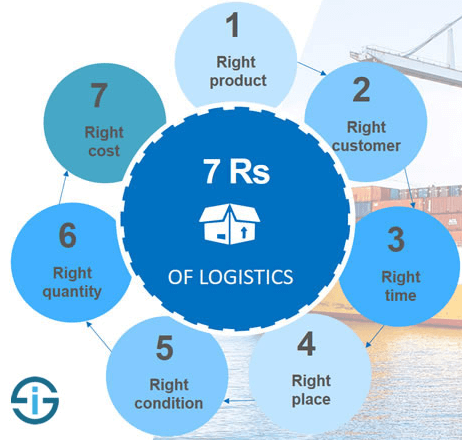

In a general sense, fulfillment means the achievement of something desired, promised, or predicted, or the meeting of a requirement, condition, or need. Accordingly, in business terms, fulfillment means that you achieve the goal of getting goods to customers—to fulfill the promise you made and ensure you meet their needs.

Efficiency is essential to the process, as you need to ensure that orders arrive quickly (customers now expect their items within 48 hours on average) and accurately (with no faulty, damaged, or incorrect goods).

Fulfillment covers the complete process, from the initial inquiry, to the customer receiving their order. It includes a number of stages, such as receiving and storing inventory, processing orders, picking items, packing boxes, and transporting goods to the final destination.

What is Shipping?

Shipping refers to the transportation of goods from one point to another, such as from a factory or warehouse to a store or from the store or warehouse to an individual customer. While many products are transported from overseas on a literal ship, “shipping” also covers transportation by trucks, trains, or air.

Shipping is one of the steps in the order fulfillment process. Ideally, it’s the final step, if the customer receives the correct product, on time, and in optimum condition. But there’s a further stage in the process if the items need to be returned.

Difference Between Shipping and Fulfillment

To recap, shipping covers only the transportation of goods, while fulfillment is the complete set of activities carried out by a business once an order is received (and before)—which includes the shipping stage. To win at fulfillment, you need to ensure each step is performed with maximum efficiency.

While every stage of the process is important, shipping is critical to overall fulfillment as it’s the point where a customer finally gets to see your product. It can also represent a significant expense, so it’s worth spending a little time on figuring out the best way to make it work.

Shipping and Fulfillment for E-Commerce

E-Commerce fulfillment and shipping refers to the process that begins when customers place an order online, instead of visiting a physical store or ordering over the phone from a printed catalog. It can apply to both business-to-business (B2B) and business-to-consumer (B2C) orders, and covers the range of delivery methods offered and the prices you charge for them.

Of course, fulfillment and shipping are important to any retail business, but the fast and furious nature of e-commerce makes it even more crucial that your processes are smooth and efficient.

Amazon is often cited as the benchmark for excellence in e-commerce fulfillment and shipping, and smaller retailers may fear that they can’t possibly compete. The good news is, with the right fulfillment process in place, you can keep pace with the big guns and keep your customers happy.

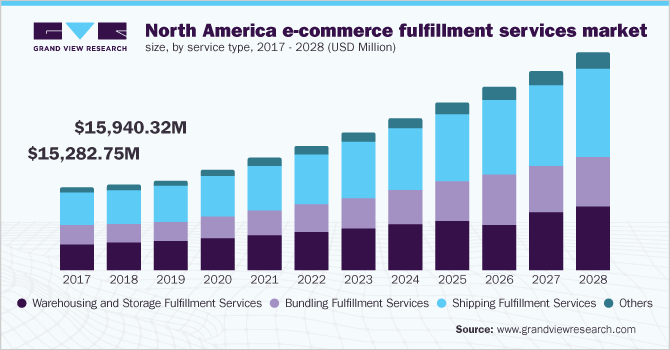

While many startups and solopreneurs decide to handle fulfillment and shipping themselves, larger companies turn to the experts. The value of the global e-commerce fulfillment services market is expected to reach $113.59 billion by 2027, which is a measure of how vital these services have become.

Source: netsolution.com

Why is it Important?

It’s important to get e-commerce shipping and fulfillment just right. If you achieve this, you’ll see the following benefits:

Meet Customer Expectations

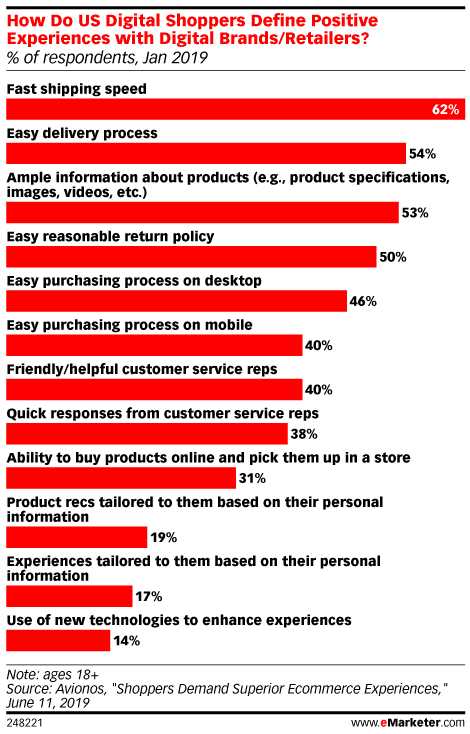

When customers choose to shop online, they’re generally doing so for convenience. As well as a smooth browsing and checkout experience, they want to get their online orders as fast as possible. Thanks to the big players in the market, their expectations are sky-high.

When you promise speedy delivery and low shipping costs, and then fulfill those promises, customers will feel good about your company—and they’ll likely share those good vibes with friends and family. That’s free advertising for you, as well as repeat custom.

Beat the Competition

The online retail world is super-competitive, with so many companies now selling products via their own websites as well as e-commerce marketplaces and platforms. Customers have plenty of choice, and can easily go elsewhere if they have a negative experience.

If you’re able to fulfill and ship orders correctly and in the optimum time, you’re more likely to keep customers, instead of driving them into the arms of your rivals. And with your operations running efficiently, you can offer little extras like custom packaging and personalized communications to give you more of an edge.

Boost Profits

Although fulfillment and shipping will incur expenses for your business, you can actually swing the balance in your favor and increase your profits. If you can optimize the process, you’ll improve customer loyalty and drive more sales.

Efficient processes also mean there’s no wasted money on damaged or inaccurate orders, which would necessitate returns at your expense. Correct warehouse storage and choosing a reliable shipping carrier will also reduce the chance of spoilage or goods being lost in transit.

See how Brightpearl can help with your accounting & inventory

How do You Fulfill and Ship Orders?

Depending on the size and type of your business, you have a few different options. If you want to fulfill in-house, you can pack the orders yourself and send them out via delivery companies like FedEx, UPS, or the US Postal Service.

Large companies often outsource the process to third-party logistics firms (more on those later), or use e-commerce fulfillment software to streamline and automate inventory management, picking, packing, and shipping.

Now let’s look at the different stages involved in fulfillment.

The 6 Steps of the Order Fulfillment Process

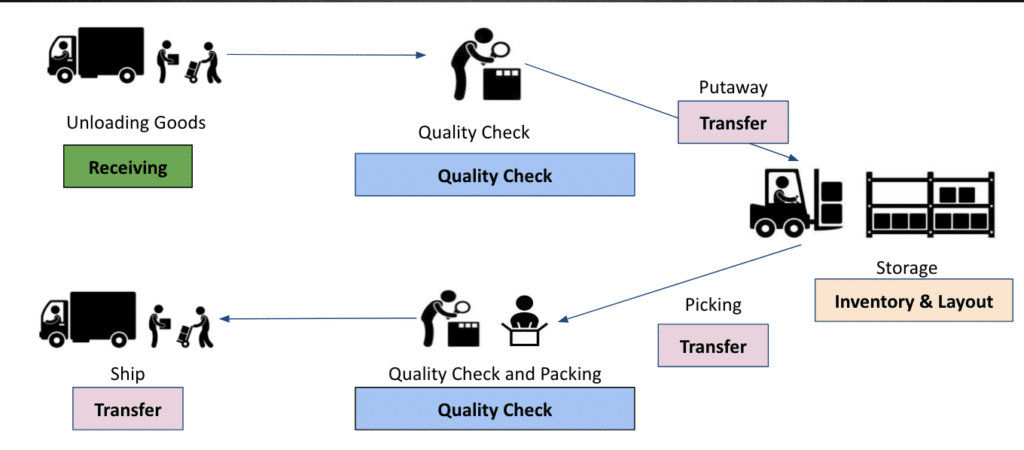

Receiving

The order fulfillment process begins long before a customer adds your products to their shopping cart. First, you have to ensure that the inventory is on hand ready for people to purchase.

For in-house fulfillment, you’ll receive stock to your warehouse or other storage facility (this might be your own garage, if you’re a very small business!). If you’re outsourcing the process to a fulfillment partner, you’ll have the inventory and necessary documentation sent to them instead.

Retailers and third-party providers all have their own processes for receiving inventory, but the basics are pretty much the same.

When goods are received, the staff count the items to ensure that they have the correct amount and that products match the descriptions provided. The goods will also be inspected for any damage sustained in transit.

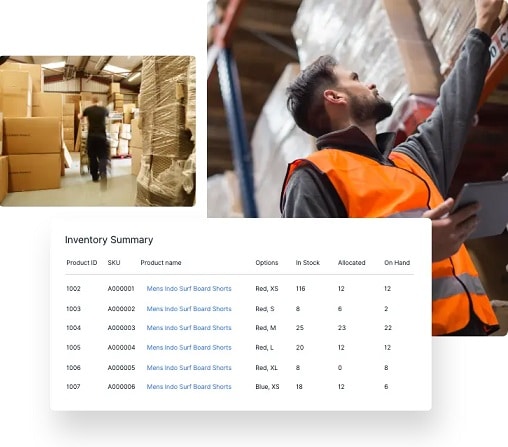

Each item, and its associated SKU (stock-keeping unit), must be recorded on an inventory list. This could be a spreadsheet or even a handwritten list, but it’s better to use inventory management software to avoid errors. Such systems often include barcode-scanning technology to locate and record items quickly.

The amount of inventory received by retailers or fulfillment partners depends on predicted demand, taking seasonal fluctuations and market changes into account. It’s important to make accurate forecasts, which is where advanced software can also help.

Source: tech.flipkart.com

Storing

Once the products have been received, checked, and recorded, they are moved to storage. Depending on the type of goods, they may be stored on pallets, shelves, or in bins, while certain items require specialist storage such as refrigeration.

Appropriate storage is vital to reduce the risks of spoilage or accidental damage, especially of fragile or perishable goods, which could lead to unnecessary costs. Security is also an important part of your warehouse management system, to guard against theft and fraud.

Your inventory should be organized as efficiently as possible, so that you always have complete visibility of stock levels and locations. Each unique product or SKU should have a separate storage location so that it’s easy for staff to find.

It might also be ordered according to expiry dates, or FIFO (first in, first out) or LIFO (last in, first out) rules. Or you might decide to make high-demand items more accessible.

Picking

With the inventory stored and ready to go, the next stage of the fulfillment process kicks in when a customer places an order through your online store. The information is communicated to the warehouse or fulfillment center staff, who will often use software to quickly identify where products are located.

The system generates a “picking slip” detailing the items, quantities, and storage locations, which the staff use to select the right goods. Once items have been picked from the shelves, a smart management system should get updated in real time to show the number of products removed and from which location.

Businesses with small order volumes usually use single or basic order picking, where the picking staff concentrate on one order at a time. This method ensures a high degree of accuracy, but it’s more labor-intensive and not so efficient for those with larger order volumes.

The next level is multi-order or batch picking, which sees several orders picked at the same time to increase efficiency. The items are then divided into their respective orders at the packing station. Because it saves time by boosting productivity, the labor costs are lower.

Source: erp-information.com

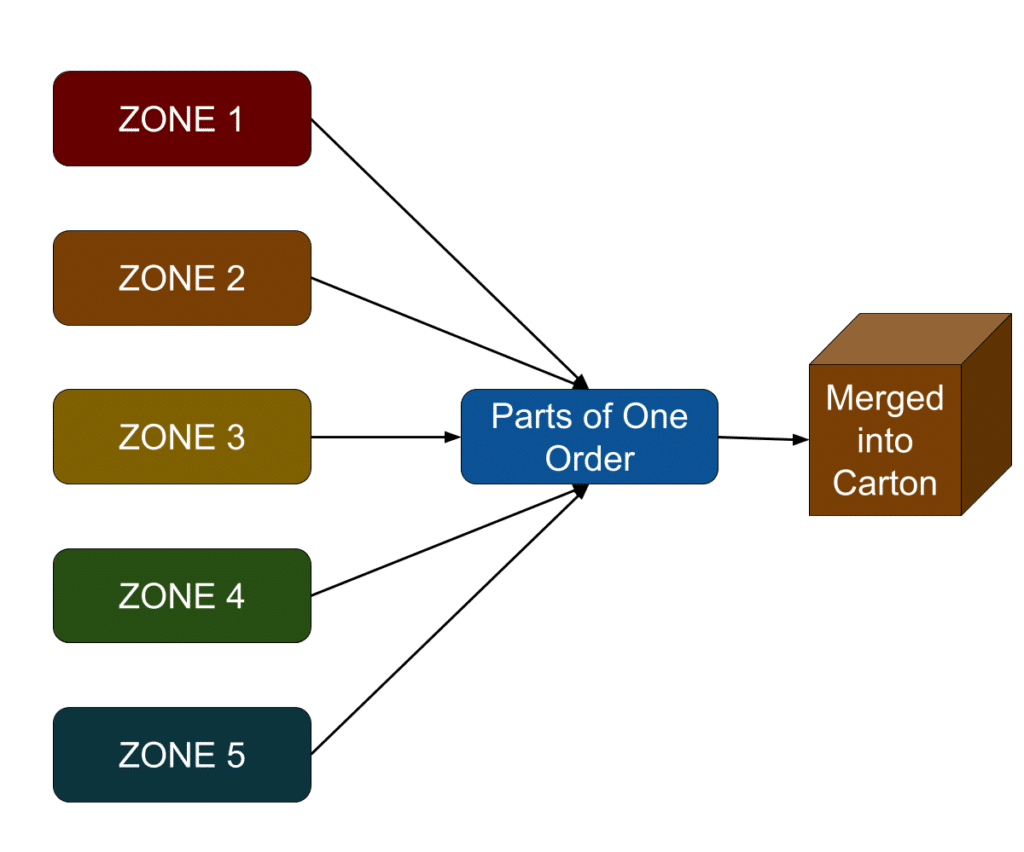

Another option is zone picking. SKUs are sorted into different zones, to which workers are assigned. They only pick items from that specific zone, and orders are moved to the packing station via conveyor belts. This is typically used by large businesses with high order volumes.

Your company may also deal with kitting, when multiple components of a product need to be manually prepared or put together before they are shipped to a customer. This can be an expensive, inefficient, and time-consuming service unless you use a smart system to locate the items quickly.

Packing

Now that the items have been picked, they are transferred to the packing area (a dedicated area of the storage facility, or possibly your kitchen table). In a fulfillment center, the documentation handed to staff may contain details on how an order should be packaged.

Choosing the most suitable packaging materials is crucial, as they need to protect the items while remaining as small and light as possible to reduce shipping costs. In some cases, specialist packaging may be required, such as bubble wrap, padded envelopes, or strengthened cartons. Some fulfillment providers charge for packing materials, while others offer standard packaging for free.

A packing slip or manifest is usually inserted with each parcel. This is a document showing the SKU numbers, weights, dimensions, and the number of units in the package. It’s checked by the packer before sealing the parcel. At the other end, the customer can check that the goods listed were actually received.

Some companies prefer to use electronic packing slips. Amazon, for example, has started to eliminate paper slips from single-box deliveries to help reduce waste.

Finally, the package is labeled. In very small companies, labels are sometimes handwritten—but this quickly becomes too time-consuming as your business grows (and it’s also prone to error). Large firms often use automation to generate shipping labels, including the specific ones required for international shipping.

Source: packworld.com

Shipping

As we mentioned earlier, shipping is a critical stage of fulfillment. It’s also the aspect over which you have the least control, because even if you take care of fulfillment in-house, you’re still trusting your products to an outside party for shipping.

Small companies may take a small number of packages to the local post office themselves, while big firms have shipping carriers collect orders from fulfillment centers. If you’re working with a 3PL partner, they may offer their own shipping—but it’s more likely that they’ll work with a major carrier.

Fulfillment service providers typically use a logic-based system to identify the best carriers for delivering your packages, based on things like weight, speed, and location. With in-house fulfillment, you’ll need to do the math and figure out the most suitable process for each order. Either way, it’s good to offer a variety of shipping options to customers.

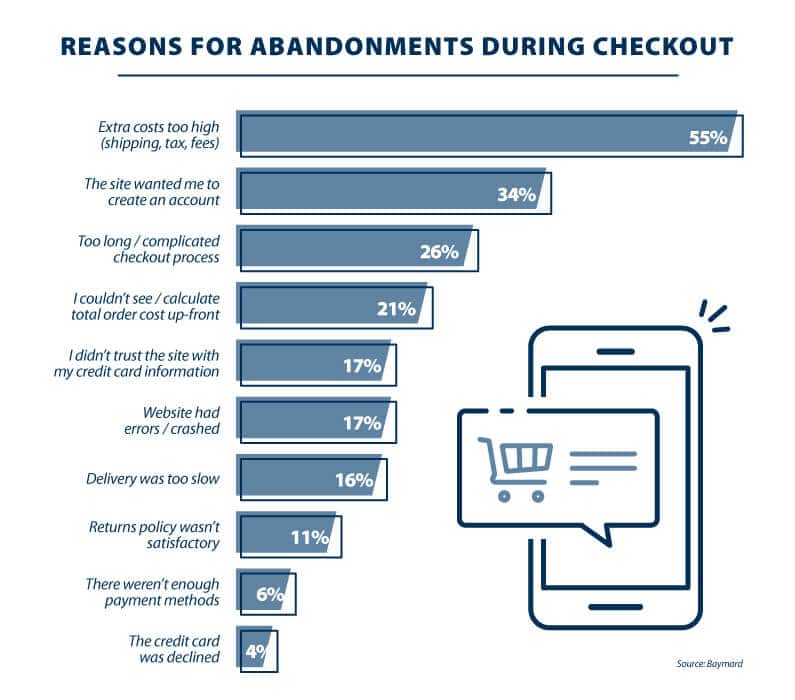

75% of customers now expect free delivery when shopping online, even on orders under $50. Standard ground shipping (within 3-5 business days) is often free, but companies can charge more for expedited shipping such as two-day, overnight, or guaranteed same day.

Once an order has been dispatched, you should receive order tracking information. This will help you keep an eye on the package’s progress, and you can share the details automatically or manually with customers, too.

Returns

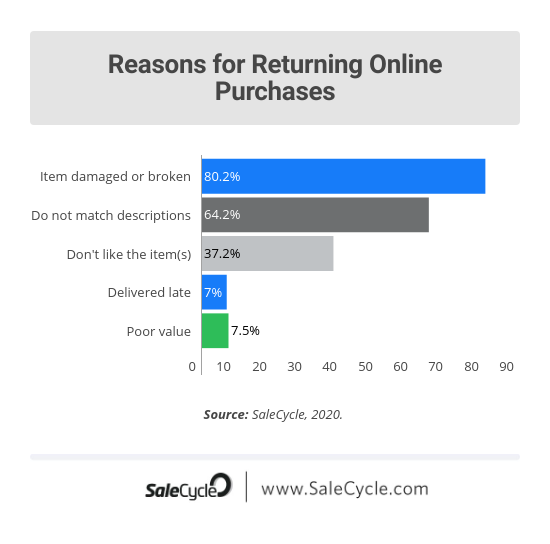

In an ideal world, customers would always receive the correct items, and decide to keep them. But in reality, that just isn’t the case! Online shoppers return 15 to 40% of purchases, compared with 5-10% of items bought in a physical store.

That’s because people can’t physically see or handle goods online, so they’re sometimes disappointed with their choice. And many people buy multiple items online with the intention of keeping just one. Then you have the issue of faulty, damaged, or incorrect orders that need to be returned.

So, some returns are unavoidable—and your warehouse team or 3PL provider needs to have a robust management system in place to handle them. The bigger your fulfillment operation, the more time you’ll spend dealing with returns.

When an item is returned purely on customer choice and there’s nothing actually wrong with it, it can be restocked. The inventory list can be updated and the product routed to the optimal storage location, after being checked thoroughly. If the item is faulty or damaged, it can be disposed of or recycled.

An efficient returns process is a big factor in a customer’s decision to buy from you—65% say they read a company’s returns policy before making a purchase. It also makes life easier for your staff. Some fulfillment solutions provide prepaid return labels and share return tracking information.

There are also integrations that will automatically text return and refund updates to customers, and route returned items directly to the e-commerce business rather than the fulfillment center.

Tips

Here are a few top tips to help you optimize e-commerce fulfillment and shipping.

1. Offer Choice

Customers are always on the lookout for a good deal, and they prefer to be offered a range of shipping prices and options, such as same-day or two-day shipping. Then, they can make an informed decision, depending on how urgently they need the item.

Consider offering a choice of returns options, too, such as buy online and return in store. And a choice of communications channels through which customers can contact you if there’s a problem. This extra flexibility will increase the chance of a sale.

2. Outsource Operations

It can be tempting to handle fulfillment and shipping yourself, especially when you’re starting out in business. But as you grow, and you find yourself spending more time on hand-packing and shipping each order, it makes more sense to implement retail operations software and/or work with a 3PL partner.

The cost of fulfillment services should soon be outweighed by your profits as you ship more items and keep more customers happy.

3. Pick the Best Location

When you’re choosing an e-commerce fulfillment company or a fulfillment center location, there are a number of factors to consider when it comes to location. Instead of just picking the nearest one to you, use your historical data to decide where’s best. Look at the shipping destination zip codes in your order history, as well as shipping zones and average time in transit.

It may seem cheaper to choose a rural fulfillment center with lower fees, but urban fulfillment centers can actually save you money because they’re closer to where most of your customers live. Otherwise, you may end up paying more in shipping costs over time because orders have to travel farther.

4. Be Clever With Costs

A good way to minimize your costs is to sign up for a business account with a shipping carrier. They are generally able to offer discounts, plus online tools such as expense tracking to help you manage the shipping side of your business.

It’s also important to keep an up-to-date list detailing the measurements and weights of all your products. You’ll be able to see at a glance how much it costs to ship each item, giving you a better idea of your total costs. And it will help you provide your customers with accurate pricing.

As a rule of thumb, your fulfillment operation shouldn’t cost more than 10 percent of sales, plus the actual shipping costs.

Source: apicsdotcoach.wordpress.com

5. Measure the Metrics

You can only tell how well your business is doing if you measure key metrics and set benchmarks to judge them by. Pretty much everything in e-commerce order fulfillment can be quantified and measured, such as:

- How many packages arrived on time

- Your perfect order rate (goods that arrived with no issues)

- How many items were returned, and why

- Time between initial order and shipping

- How long packages took to pick and pack

- Cart abandonment rate

- Overall customer satisfaction (CSAT) scores

If you discover more problems than successes, look at the reasons why this happened. Were these factors outside your control (delays due to bad weather or global supply chains), or were they caused by inefficient processes (inability to locate items quickly, damage due to improper storage, being unprepared for seasonal demand)?

Look at what you could do differently, and put the necessary steps in place to fix the problem. Then measure the metrics again!

Best Practices

Optimized fulfillment and shipping won’t happen overnight, but there are plenty of best practices you can adopt in order to lay the foundations.

1. Understand the System

It might sound obvious, but it’s crucial to ensure that everyone in the team understands the overall process and why each stage is important. You need to set up a system that’s robust enough to handle complex fulfillment and shipping processes, but also transparent and easy to follow.

When everybody knows their role and is aware of how it fits into the bigger picture, your operations should run more smoothly. As well as choosing the fulfillment model that makes the most sense for your business, you should underline the importance of the customer experience so that customer satisfaction is at the heart of every process.

Source: arviem.com

2. Plan for Contingencies

No matter how well you’ve planned and implemented it, there’s no such thing as a perfect system! Sometimes things will go wrong—some are beyond your control, others you can do something about. The key is to put contingency plans in place to mitigate against potential problems.

These could include spoilage or theft of stock, a natural disaster that delays delivery, or a partner such as a supplier or shipping carrier going bust. Unprecedented spikes in demand can also throw a spanner in the works. What would you do in those situations? How could you work around the issues to deliver great service?

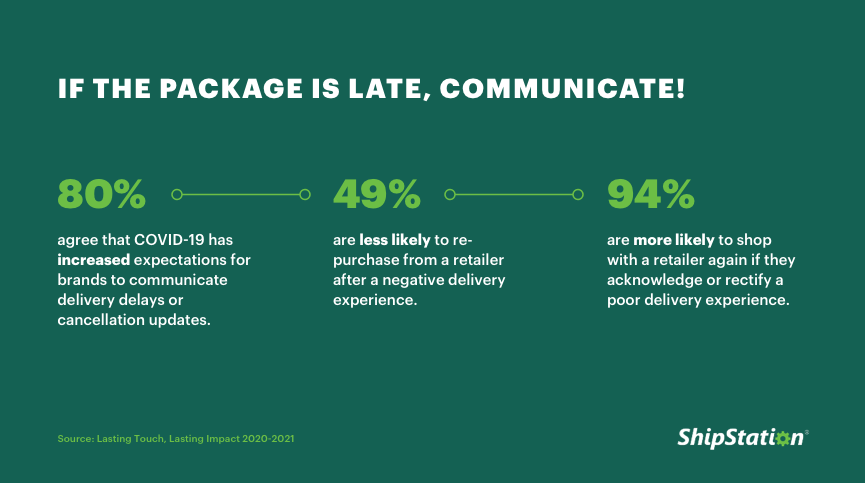

In the event of problems, it’s vital to have great customer support in place. You need to communicate with your customers, and handle complaints swiftly and politely. But don’t forget that your business also requires great support from fulfillment partners and software providers.

Brightpearl, for example, gives you a dedicated Customer Success team, as well as unlimited phone and email support.

3. Be Transparent

Whether things are going swimmingly or a problem crops up, it’s always good practice to keep customers in the loop. You can inspire customer confidence in your company by providing lots of information on your website without them having to search for it.

For instance, you can display a choice of shipping speeds at checkout, as well as details of things like additional customs fees. Customers can then make more informed decisions, and they won’t be surprised by unexpected costs.

Give them the option of tracking their package—78% of consumers say they want to receive updates on the status of their orders. And if there’s going to be an unavoidable delay in receiving their order, let them know.

4. Optimize Productivity

Productivity is the key to everything from reducing business costs to keeping customers satisfied. Having an efficient fulfillment and shipping system will help your staff to be as productive as possible, but you also need to ensure every team member knows how to do their job and has the means to do it well.

Optimized storage, barcode scanning, and detailed packing slips are all ways to boost productivity, as they reduce the amount of time needed to pick and pack each order. You can then operate with fewer staff at slower times. It goes without saying that a safe and pleasant working environment improves worker happiness, which also improves productivity.

5. Use the Best Tools

Optimizing productivity and efficiency requires the best tools for the job, including things like warehouse automation, real-time inventory updates, and advanced forecasting.

If you’re still using spreadsheets and manual data entry for your inventory, you’re wasting time and risking costly errors. And a lack of automation means slower processes and less transparency (for you and your customers).

The best software has all the core functionality in one handy package, so that the entire fulfillment and shipping process is handled from one central hub.

For example, Brightpearl’s advanced retail system speeds up order fulfillment by providing the ability to automate all the time-consuming tasks, as well as automatically updating multichannel inventory levels and accounting data as soon as items are shipped.

Your E-Commerce Fulfillment Strategy

With customer expectations increasing, efficient order fulfillment is more important than ever—so you need a successful strategy to handle it. This will depend on all sorts of factors, such as your business size and type, your location (and that of your customers), which sales channels you use, and how much customization you need.

There are a number of different fulfillment options to choose from, and you should do some careful research before deciding which provider or method will best suit your business.

How to Develop a Fulfillment Strategy

First, you need to choose whether to handle fulfillment in-house, or outsource it to a partner. Let’s take a look at some of the choices.

Types of Fulfillment Provider

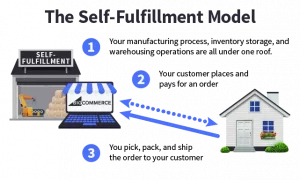

In-House or Self-Fulfillment

This basically means that your business completes each step of the fulfillment process by itself, with no outside assistance. It’s often used when companies are just starting out, maybe working from home or a small office. However, some large businesses also prefer to keep fulfillment in-house, as it gives them total control over their operations.

As a small business owner, you’ll be accepting orders and packing boxes yourself, and taking them to the post office or sending them via a carrier like FedEx. If you only have low order volumes, it’s a good way to reduce costs—but as your business grows, you’ll want to spend more time on things like customer acquisition, product development, and marketing campaigns.

Eventually, as the operation outgrows its startup roots, you’ll need somewhere to store your products. You can either rent warehouse space or buy your own facility. Either way, costs will increase as you’ll be responsible for recruitment and staffing, warehouse equipment and management software, and insurance.

If all this becomes too much of a headache, you could consider outsourcing order fulfillment and shipping to a third-party provider.

Source: bigcommerce.com

Third-Party Fulfillment

Third-party logistics (3PL) fulfillment sees businesses pass the responsibility for post-purchase operations to an expert partner. You might choose a 3PL company based on its location, specialization, or promised turnaround time.

3PL firms handle most or all aspects of supply chain management and logistics, including order processing, warehousing, and shipping orders. This solution is ideal for e-commerce companies that are ready to scale up.

Your 3PL partner stores your inventory at one or more fulfillment centers, which are designed to turn inventory over quickly—great for companies whose products are selling fast. Because you’ll have access to more space, inventory can be purchased in bulk in order to improve your profit margins.

When an order comes in, your fulfillment partner will automatically be forwarded the order to pick, pack, and ship it on your behalf. Inventory is stored so it is ready to be shipped as soon as an order is placed, and inventory levels are synced with your e-commerce store.

Fulfillment by Amazon (FBA) is a prime example, where an Amazon seller sends their products directly to Amazon fulfillment centers to be stored and shipped. The Shopify Fulfillment Network operates on similar lines. Using an advanced Retail Operating System like Brightpearl, along with FBA and/or SFN allows you to make the most of each fulfillment provider.

There are many benefits to outsourcing fulfillment. For example, 3PL partners use automation to boost efficiency, and they are able to negotiate cheaper shipping rates because they ship large quantities for multiple vendors. No investment is required for warehouse space, or for staffing. You also don’t need to license your own warehouse management software.

Shipping times are also reduced, because you can choose to store your inventory closer to the majority of your customers. Urban fulfillment centers are on the rise as they allow businesses to quickly and affordably ship to customers in big cities with large populations.

Source: beyondwarehousing.com

However, the downside of 3PL fulfillment is that you don’t get total control over your processes—you have to trust your partner to deliver a quality service. You need to choose wisely, as the experience they provide will have a huge effect on customer satisfaction and customer lifetime value.

A 3PL fulfillment center is usually more expensive than a storage-only center, especially if you have lots of product lines (it’s most cost-effective for those with a low SKU count). Costs vary based on the center you’re using—some charge by pallet or per unit, others by hours of work.

Each 3PL will offer varying services, possibly including things like kitting, B2B orders, temperature control, or refrigeration. But if you want something unique, such as custom packaging, you’ll have to pay extra for it.

If you’re happy to hand over the whole operation to logistics experts, there’s another option. Fourth-party logistics (4PL) firms manage and optimize a business’s supply chain from end to end, including all 3PL services (compared to a 3PL provider who focuses on the day-to-day operations of your supply chain logistics).

Dropshipping

An alternative to in-house or third-party fulfillment is dropshipping. This is when the manufacturer who produces your products is also responsible for storage, picking, packing, and shipping. When a customer places an order with you, you pass it to the manufacturer which delivers the goods directly to their destination.

In this model, you are never actually in possession of the products sold on your online store. Instead, you act as a “middleman”. All you need to do is to display the items on your website for the customer to see, and handle the sales aspect of the process.

This can be an attractive solution for new and small businesses because of the lack of overheads. If you want to expand into new areas or test the viability of a new market, you can establish a dropshipping service in that location without the cost and risk of setting up a warehouse there.

Source: nexcess.net

Dropshipping is very competitive because the overheads are so low and virtually any company can do it. The problem is that you don’t get full control over inventory management and order fulfillment, so it’s harder to keep an eye on quality—and there’s much less visibility when it comes to tracking.

The shipping process is completely in the hands of the manufacturer, which might even be based overseas. This often means transit times are increased and subject to unforeseen delays—and delivery can prove very expensive.

Dropshipping also makes it difficult to offer custom products, so it’s harder to establish a unique brand. And as the business scales up, you might find yourself facing the logistical nightmare of coordinating with multiple dropshippers.

Hybrid

Of course, if you don’t think any of those options is entirely right for you, it’s possible to implement a hybrid solution combining two or more of them. This model works well where there is a diverse supply chain, because you might find that one method is better suited to a certain product, while a different solution could be used for other items.

For example, maybe most of your products are purchased by customers living in close proximity to your business. But you also sell a smaller percentage to consumers farther afield.

In this case, you could use in-house fulfillment for the local orders, but outsource to a 3PL to fulfill the national or international orders. And if you sell extras alongside your main high-value product, you could choose dropshipping for these.

If you’re using the hybrid method then using an advanced system like Brightpearl is key. You can easily automate the choice between 3PL, in-house & dropshipping by using pre-set conditions.

Your E-Commerce Shipping Strategy

As we’ve mentioned, shipping is an essential component of e-commerce fulfillment, and you need a specific strategy to cover it. This stage is all about balancing the needs of your business and those of your customers—you need to find the most cost-effective way to ship your products while meeting increasingly high customer expectations.

Transparency is important here, as you need to make all the costs clear to your customers at the outset. You should also ask for full visibility of shipping fees charged by your 3PL partner, to ensure they’re giving you the best deal.

Key Factors for Defining Your Shipping Strategy

Now let’s take a look at the major factors involved in your shipping strategy, and how they fit together.

Shipping Costs

All shipping carriers base their costs on a variety of factors, such as:

- Package size and weight

- Origin and destination address

- Product costs

- Transaction fees

- Customs/duties (for international shipping)

- Tracking and insurance.

Carriers usually include shipping calculators on their websites so you can get an accurate idea of costs in the US or overseas. You can work out your average shipping cost, and factor this into your overall budget.

We know that customers have come to expect expedited shipping, but shouldering the cost of this can put a big dent in your profit margins. So, you need to decide whether you’re going to pass the full cost of shipping on to your customers, or absorb some or all of it yourself.

Offering your customers free shipping is one of the best ways to reduce cart abandonment, but you may have to increase product prices to cover the costs. However, customers may not mind or even notice this, as they will be attracted by the idea of free or discounted shipping even if the cost of the item itself is a little higher than average.

Source: blog.wishpond.com

You could decide to introduce a small product price increase that would partially cover the cost of shipping. Or you might offer a discount code for free shipping to certain customers, but not all of them at once. Alternatively, you could pay the full price of shipping out of your margins, in order to offer free shipping without hiking product prices.

Shipping insurance and tracking are optional extras rather than essentials, but they are important to customers—and with most carriers, they’re relatively inexpensive. It’s worth considering insurance on high-value items.

Shipping Rates

Next, you need to decide what type of shipping rates you’re going to offer. One popular option is flat-rate shipping, which keeps things simple as the fee doesn’t vary according to product type. Both you and your customers will know exactly what the price is. The main thing to remember is not to drastically undercharge or overcharge your customers.

Flat-rate shipping is most suitable when all the products you sell have fairly similar dimensions and weights, such as jewelry items. FedEx offers a flat rate shipping service called One Rate, where you don’t have to weigh or measure the package if it’s under 50lbs. It also works well for subscription fulfillment, which is the shipping of products on a regular, predetermined basis.

As a rule of thumb, if your largest product can fit into one of the standard boxes, you can charge a consistent shipping rate. But if your products vary widely in size and weight, things become more complicated and less effective—you can’t charge the same rate for both a wardrobe and a sweater!

Instead of flat-rate shipping, you could charge real-time carrier rates. Many e-commerce platforms can integrate in real-time with carriers like USPS and Canada Post to generate shipping options and live pricing. This allows your customers to choose and pay for the exact service they want.

Another alternative is to offer shipping rates based on the total price of items in a customer’s cart, or on a minimum order amount. This rewards customers who spend more, and also encourages them to buy that extra item they weren’t quite sure about, in order to qualify for free or cheaper shipping. It helps you offset the costs of shipping by helping to increase your average order size.

Shipping Methods

Customers appreciate multiple shipping options, which give them the choice of paying more for urgent items, or paying less and waiting longer for others. A massive 88% of consumers say they are willing to pay extra for next-day or same-day delivery. High-end retailers, whose customers expect exceptional service, often offer expedited delivery options.

At the user end, customers will see a menu of shipping methods to choose from, such as same-day, next-day, two-day, or standard. But in order to offer these choices, you need to work out which mode of transportation will allow you to deliver in the chosen time frame.

You can decide to send goods by road, rail, sea, or air, depending on the customer location, the delivery speed, and the overall price. The costs and timings will also vary according to product type and time of year.

If you work with a fulfillment partner, then it’s up to them to work out which is the best method and carrier for each order. Overland transportation is suitable for heavy goods, while air is best for perishables as it’s faster—but it’s also more expensive.

For local customers, you might choose to set a delivery area using a radius or a list of zip codes. Customers within this defined area can select “local delivery” as a shipping method at checkout, and take advantage of the cheaper price.

Source: nexcess.net

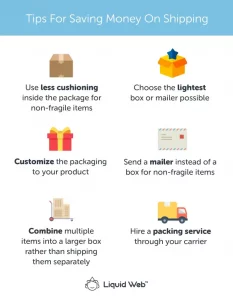

Packaging

The cost of packaging also needs to be factored into your shipping strategy. Obviously, the most important thing is that it protects your products from damage, but you need to strike a balance between protection and weight. If the packaging adds too much weight to an inexpensive product, your shipping costs could total more than your profits.

Size is also important—can your products fit into flat envelopes, or do they need to be in boxes? Poly mailers are good for items that don’t need much structure or cushioning, as they’re lightweight and can be adjusted to different product volumes and weights. But if you sell fragile products, be prepared to pay more in shipping costs.

Keeping your packaging as small and light as possible is not only better for your profit margins, it’s also better for the environment. Some firms are now using eco-friendly packaging, even if it costs more, to do their bit for the planet and appeal to green-minded customers.

You can order free packaging from some carriers such as USPS, UPS, or DHL, but you may want to use custom packaging to enhance your brand identity. Paying attention to the presentation will also impress customers, so think about personalized inserts or notes, branded stickers, and maybe even a small free gift.

If the “unboxing” experience is impressive enough, the recipient may even share it on social media, which means free advertising for you!

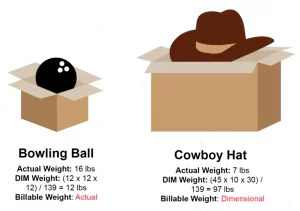

Product Weight and Packaging Weight

As we mentioned earlier, it’s a good idea to keep an up-to-date list of product measurements and weights, so that the information is readily on hand for you, your carrier, and your customers. If you’re using standardized packaging, you should list its weight and dimensions, too.

Carriers usually have predefined limitations on package sizes and weights, so it’s easy to find out how much they’ll charge for certain items. Some carriers calculate the weight of your products by not only the item’s weight, but the shape and size of the parcel as well.

Source: oberlo.com

This is known as DIM weight pricing (dimensional weight pricing), where the length, width, and height of the parcel are multiplied to get a number which equals cubic inches. That number is then divided by a DIM divisor (chosen by the carrier) which gives you the total “weight” in pounds.

Policies differ between carriers, but if your dimensional weight is larger than your order’s weight, your customer may be charged for the dimensional weight of the order.

Inventory strategy

To be able to fulfill and ship orders efficiently, you need to ensure you always have the right inventory in the right places at the right time—and for that, you need a great inventory management system.

You don’t want to order too much and be left with obsolete stock, nor do you want to run out of products and disappoint customers. A smart system will also reduce the risk of inaccurate orders being sent out by mistake, and take the stress out of locating products and carrying out audits.

Your inventory management system should allow you to set a reorder point or Periodic Automatic Replenishment (PAR) level, which is the minimum quantity of products you need to have on hand at any time. It should also automatically trigger a reorder when a product reaches that level.

There are several different types of inventory strategy:

- Push, where seasonal products are procured and “pushed” to customers at the optimum times

- Pull, where items are “pulled” from the store or warehouse as and when customers order them

- Just-In-Time (JIT), when products are timed to arrive at the last moment to avoid keeping lots of stock.

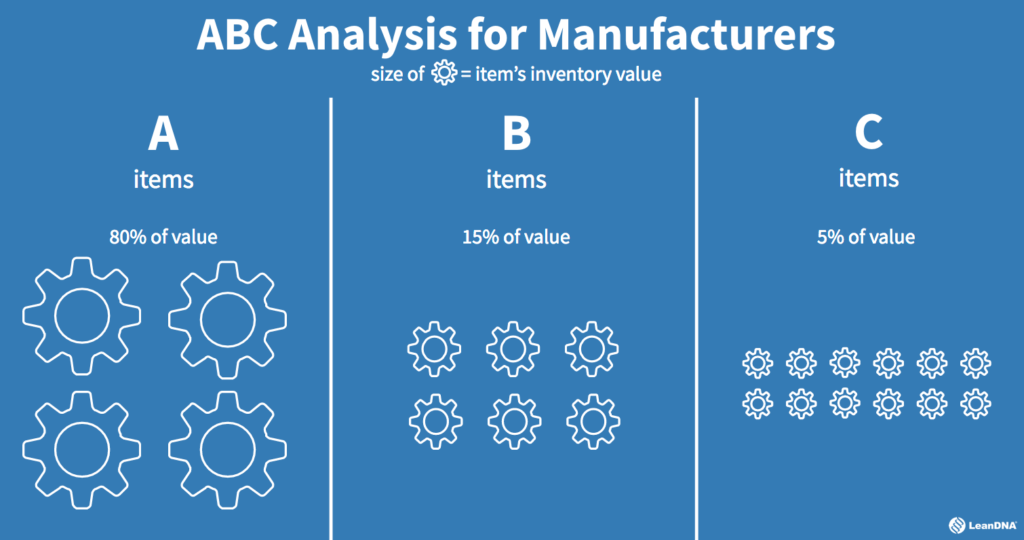

Many businesses use the ABC method to prioritize high-selling products. This is where you categorize items according to how important they are to your business—so “A” products are worth 80% of your sales, “Bs” are worth 15%, and “Cs” 5%. “As” are the ones you never want to run out of.

Source: leandna.com

Storage and Warehousing

Just like inventory, warehousing also needs to be optimized to ensure accurate and timely fulfillment.

Warehouse staff should be able to locate products quickly when an order comes in, and get them picked, packed, and shipped as soon as possible. For this, they need efficient tools and automation, such as barcode scanning or RFID (radio frequency identification).

It’s also important to ensure appropriate storage space for your products, whether it’s in your own warehouse or at a fulfillment center. You need to know exactly what you have and what’s due to arrive, so that you can choose the right facility—it’s not efficient to pay for space you’re not using, or to cram stuff into a small area.

The right storage is especially important for fragile or perishable goods, as damage or spoilage will cost you money and delay fulfillment. Using First In, First Out (FIFO) rules is helpful as they make sure the oldest stock is sent out first. This also works for non-perishable items, where you don’t want to send dusty boxes or out-of-date packaging to the customer.

Inventory Forecasting

You can only hold the right amount of inventory if you have some idea of how many customer orders to expect. This makes inventory forecasting an essential part of fulfillment—it helps you predict peak times and current trends so that you know how much stock to order and when.

Take a look at your historical orders and see which products sold best at what times. Seasonal peaks, market changes, and the actions of your competitors can all have a bearing on your forecasts, helping you to evaluate your PAR levels and budget for things like marketing.

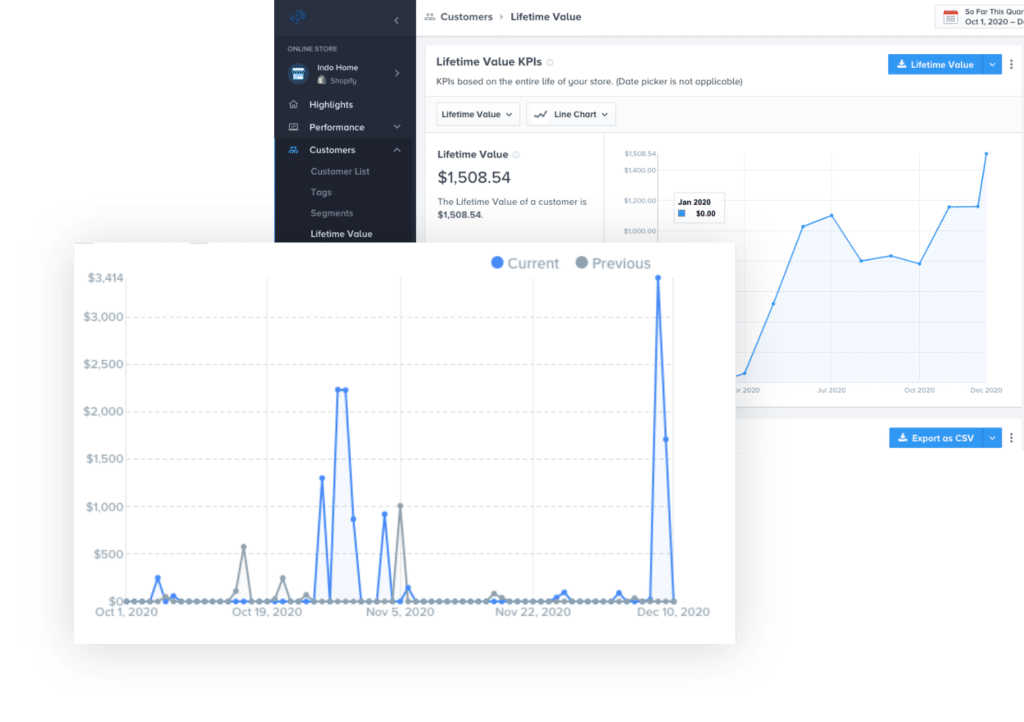

This is where advanced software like Brightpearl comes in, giving you real-time data and detailed reports so that you have all the information you need.

How Brightpearl Can Help

In order to achieve successful shipping and fulfillment, you need to be super-organized—so it makes sense to use software that keeps all your vital data in one place. Brightpearl does just that, while its many advanced features have been designed especially for retail and wholesale businesses.

Features

Brightpearl has a powerful Automation Engine that enables you to automate your entire order-to-cash process. With inventory levels automatically updated and barcode scanning tech to quickly find products in the warehouse, you can easily manage large operations across multiple channels and locations.

The tool automates all repeatable order management tasks, with customizable rule-based workflows that take minutes to set up and change. You can set it up to automatically route products to a warehouse, replenish goods via the low inventory report, or select shipping carriers.

Complex order fulfillment is also possible with this level of automation, allowing you to pick the best fulfillment option for each sales channel—including partial fulfillment, dropshipping, multi-location fulfillment, or Fulfillment By Amazon.

Another of Brightpearl’s amazing features is the intuitive Inventory Planner. By bringing in your historical sales data (taking into account any sales or peak periods), you’ll get recommendations on the best products to stock up and even those slow-selling products that you should discount or liquidate so you can optimize your product mix. You can even create a Purchase order from your replenishment report with just a couple of clicks.

Further features include purchasing and supplier management, advanced analytics and reporting, and business intelligence.

Integrations

Brightpearl has a vast range of pre-built, high-performance Plug & Play integrations and connectors to third-party apps and services. Because these are maintained in-house, they come with enterprise-class reliability and can handle high-transaction volumes.

Seamless integrations and two-way syncing with online marketplaces and e-commerce platforms such as Shopify, Amazon, and BigCommerce make it easy to sell on multiple channels without losing track of your inventory. The central system is immediately updated when a sale occurs anywhere, and sales credits and refunds are taken into account.

Brightpearl also integrates with various 3PL partners, plus shipping carriers such as FedEx, UPS, Royal Mail, and ShipBob, so that you have full visibility of your order status.

Benefits

Speed and Accuracy

Brightpearl’s automation speeds up all your repeatable processes for increased productivity, and ensures greater accuracy of everything from picking and packing to forecasting. With all your systems in one place, it’s easier to get every order right the first time.

Cost Reduction

This enhanced efficiency leads to cost savings, as stock will be processed faster and you may require fewer warehouse staff and smaller storage spaces. Smart systems also mean less obsolete or damaged stock, as well as fewer returns.

Scalability

Brightpearl supports your business as it grows, with tools and integrations enabling you to expand your operations to cover multichannel selling. Physical stores are connected by POS, and you can even go global with multi-currency support.

Happy Customers

Inventory tracking helps you avoid stockouts and disappointed customers. You can also offer fast shipping times to attract more custom, and consumers will be delighted to receive the correct order in the optimum time (with personalization to build your brand).

Built for Retail

Because it’s built specifically for retailers, Brightpearl has all the features you’ll need—which means no costly customizations are required.

Constant Support

You’ll receive 24/7 support throughout the partnership, with retail and technology experts accompanying you from scoping to implementation and beyond.

Optimize Your Shipping and Fulfillment

Shipping and fulfillment are essential components of any e-commerce business, and you need to nail them if you want to keep your customers and outshine your competition. Brightpearl’s dedicated retail operations platform can help you optimize the process with advanced automation, extensive functionality, and expert support.

With an efficient fulfillment and shipping system in place, you can ensure all orders arrive quickly and accurately—with no need for returns. The increase in productivity and reduction in costs will enable you to grow your business, reach more customers, and boost your profits.

FAQs

How do I Fulfill Orders on Amazon and eBay?

Amazon offers three options. The first, Fulfillment by Amazon (FBA), sees Amazon manage every stage of the order on your behalf. You’ll want to sell products quickly, as there are additional fees for products held in their distribution centers for longer than six months.

Fulfillment by Merchant (FBM) makes you responsible for order management, but you get full control over customization and customer experience. You have to keep on top of things, though, as Amazon doesn’t tolerate mistakes. And FBA merchants are usually prioritized above FBM merchants in search results.

Seller Fulfilled Prime (SFP) lets you avoid the high costs associated with Amazon fulfillment, yet still reach the wider Amazon audience including Prime members. For this, you have to meet a strict set of requirements.

eBay doesn’t have its own in-house fulfillment network, but there are other options. You can choose manual updates within eBay, which is okay for low-volume sales but quickly becomes time consuming and prone to errors.

eBay also offers Fulfillment by Amazon, where you use Amazon fulfillment centers for eBay orders. It gives you global reach, but your orders will arrive in Amazon packaging, which can confuse customers! Amazon also charges a premium to fulfill orders that haven’t been bought via Amazon itself.

Another choice is to use an eBay fulfillment partner such as Radial or Selery. They have the experience to negotiate discounted shipping and courier rates, but you’ll lose control over quality. Finally, you could implement order management software that integrates with eBay (like you get with Brightpearl) so you can fulfill and ship from a centralized system.

How do I Fulfill Orders on Shopify?

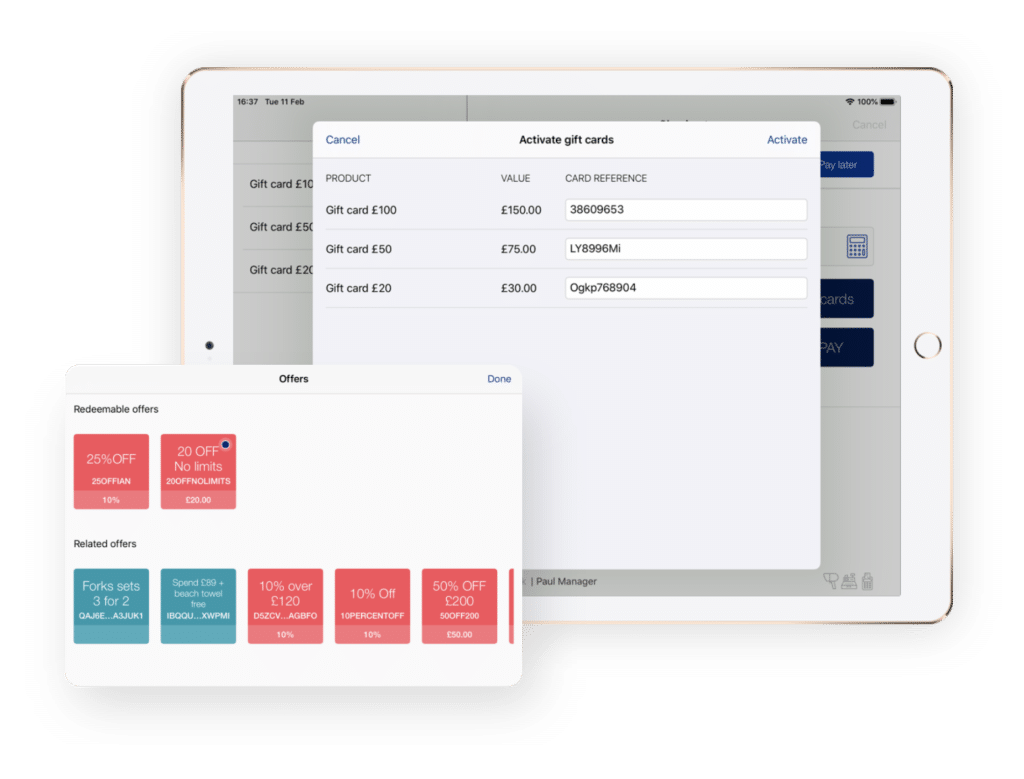

You can choose to fulfill your own orders, use third-party fulfillment services, or a combination of methods. When you add a product to your store, you select a fulfillment method for it (you can change the setting for multiple products at once by using the bulk editor).

You can then fulfill orders automatically or manually. With the manual method, you have to manually open and fulfill an order after it’s been placed. Automatic fulfillment is the least time-consuming method, but it can’t handle partial fulfillment, local pickup orders, or multiple locations.

Your best bet is to use Brightpearl’s Shopify integration to take advantage of the automated fulfillment tools and save yourself a lot of time.

What is a Fulfillment Center?

Not to be confused with a standard warehouse, a fulfillment center is a physical location belonging to a third-party logistics (3PL) or fulfillment provider. These providers use the centers to fulfill customer orders on behalf of e-commerce retailers.