Introduction

When it comes to order fulfillment and the all important pick-pack-ship process, it’s important to follow recommended retail best practice. Using Brightpearl as an example system, we’ll demonstrate the different parts of the order fulfillment process and how this should work within back office software. You can of course customize this workflow to suit based on your business, supply chain, and whether you’re sending orders to customers or retailers. Get ready for some valuable insight into pick, pack, ship best practice.

Efficient Fulfillment Services

When you run your warehouse through Brightpearl, instead of being logged into multiple sales channels, your staff can work in the same system as every other department. This means that as soon as an order is placed, it’s there for the warehouse team to pick up in real-time; if the accounting department put an order on hold pending payment, they can see this and act accordingly.

And communication works the other way too. As orders are picked, packed and shipped at your fulfillment center, updates are captured in Brightpearl for all to see. If a customer calls with a tracking number, your customer service team can see, in Brightpearl, exactly where that order is.

Pick, Pack, and Ship Process Flow

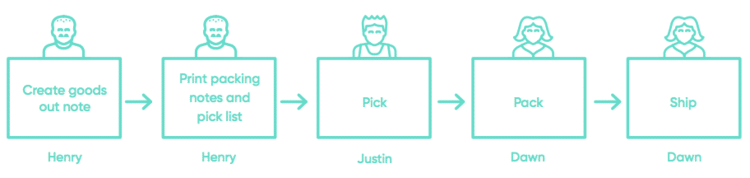

As mentioned in the previous section, goods out notes in Brightpearl follow a Print, Pick, Pack, Ship workflow. This is our recommended and most commonly used workflow, and it’s what we’re going to detail here, but it’s not the only way to work with us. To walk us through the pick, pack and ship process, let’s create a company, a warehouse, and a few members of staff.

Meet the team

- Henry the Warehouse Manager

- Justin the Picker

- Dawn the Packer

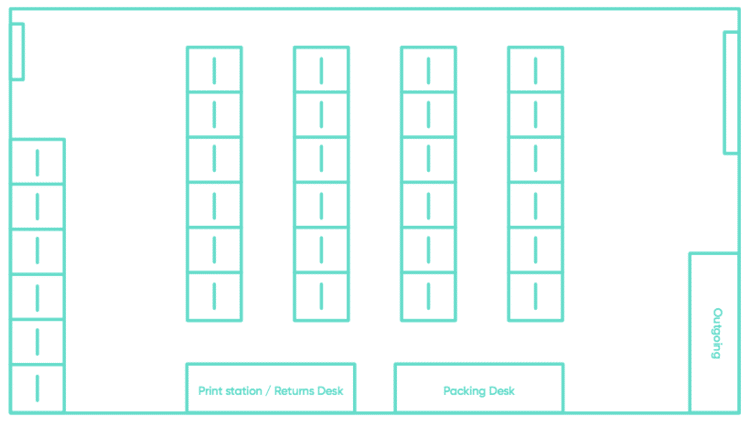

These three superstars form the warehouse team at ‘Outer Heaven Retail’, a relatively small business fulfilling roughly 200 shipments a day from their 2000 square foot warehouse, with each order usually containing two items. Outer Heaven Retail are an apparel company, with around 1000 SKUs recorded in their inventory management software, and their warehouse is set out as below.

The warehouse

To make the most efficient use of Brightpearl, you can also capture all of your warehouse locations, with up to four levels of hierarchy – Aisle, Shelf, Bin and Bay.

So, enough context, here’s an overview diagram of the workflow before we dive into the click-by-click details:

1. Create goods out note

Goods out notes are the first step in Brightpearl’s shipping process. To create a goods out note (otherwise called a shipment note or packing note), you need to fulfill an order. In our workflow, Henry is fulfilling the orders, but in some businesses, this is done by sales or account managers instead.

- Henry filters and selects all orders that match his criteria of ‘Due to ship’ and ‘Paid in full’

- Selecting to fulfill the orders gives an option to update the sales status, which Henry does to ‘Processing’, and leaves the shipping method as ‘Inherit from sale’

Tip: Any filters that you use on a regular basis can be set up as favorites, meaning that they are only one click away rather than having to build the filter every time!

2. Print packing notes and picking list

Next, Henry needs to kick off the next batch of goods out notes by producing the individual packing notes, and a consolidated picking list to help with an efficient pick process.

- Under Goods out note > Due to Ship, Henry selects a batch of 50 goods out notes and selects to Print and Pick them

- The result of this is that the goods out notes are marked as printed and picked; all packing notes are produced in one tab, and the picking list in another

- Henry prints them all out, and hands them over to Justin who’s eagerly waiting with his trolley

Tip: If you select ‘Show Filter’, we have a range of other filters available so that you can find and select goods out notes as fits your prioritization. For example, if you’ve had a flash sale, you can opt to just return single item shipments, to clear them out first.

3. Pick

Justin works from the pick list rather than the packing notes, meaning that he’s running around filling up his trolley with all the items required to fulfill the current batch of goods out notes. There are a few different piece picking methods. In this warehouse, Justin is likely to use discrete order picking, doing one order at a time. However, businesses with larger warehouses or more staff might opt for batch picking or zone picking.

Once he’s finished the run, the trolley is parked at the packing bay along with the stack of packing notes.

4. Pack

Time for the final step in order assembly, where the full trolley gets divided up into the individual packages and assigned shipping labels. It’s also time for quality control – Dawn needs to check all the items she packs are intact and correct. Her pack process is as follows:

- Picking one at a time from the batch of printed packing notes, Dawn works her way through each by selecting the items from the trolley and boxing them up with appropriate packing materials

- Once complete, she selects the goods out note in Brightpearl and hits ‘Pack’

- Outer Heaven Retail uses a carrier integration, such as ShipStation or Shiptheory (more on this later), and this is set to automatically generate and print the shipping label at this point

- Dawn adds the packing slip, seals the package, sticks the shipping label on, then puts the package in the ‘awaiting pickup’ bay

For companies that use multiple carriers, the pickup bay may be sectioned between Fedex, USPS, and other shippers.

Tip: Within the Pack modal, there are some optional features to alert the customer that their shipment is ready and awaiting carrier pickup, which is great for customer service. There’s also a field for capturing tracking references. Any references added by your packer, or via a carrier integration app, will be relayed back to your sales channel automatically.

5. Ship

This is the only compulsory step in the pick, pack and ship process.

Clicking ship in Brightpearl not only triggers inventory adjustments and accounting entries, but also sends updates back to your e-commerce sales channels, letting your customer know their order is on the way to them. Outer Heaven’s ship system is:

- When the carrier arrives, Dawn pulls up the goods out notes that are ‘Due to Ship’

- Selecting them all, she hits ‘Ship’

- The result is that these goods out notes will now be cleared from view, and locked from further editing. This will have also updated the sales order or warehouse transfer that they belonged to, as well as posting accounting entries for the inventory level adjustments.

Tip: If you’re using multiple carriers for any reason, we have a filter for ‘Shipping method’, so you can find the goods out notes that need updating as quickly as possible.

Pick, Pack, and Ship Software examples

There are plenty of software solutions to help you achieve pick, pack, ship best practice. Here are three examples:

Brightpearl

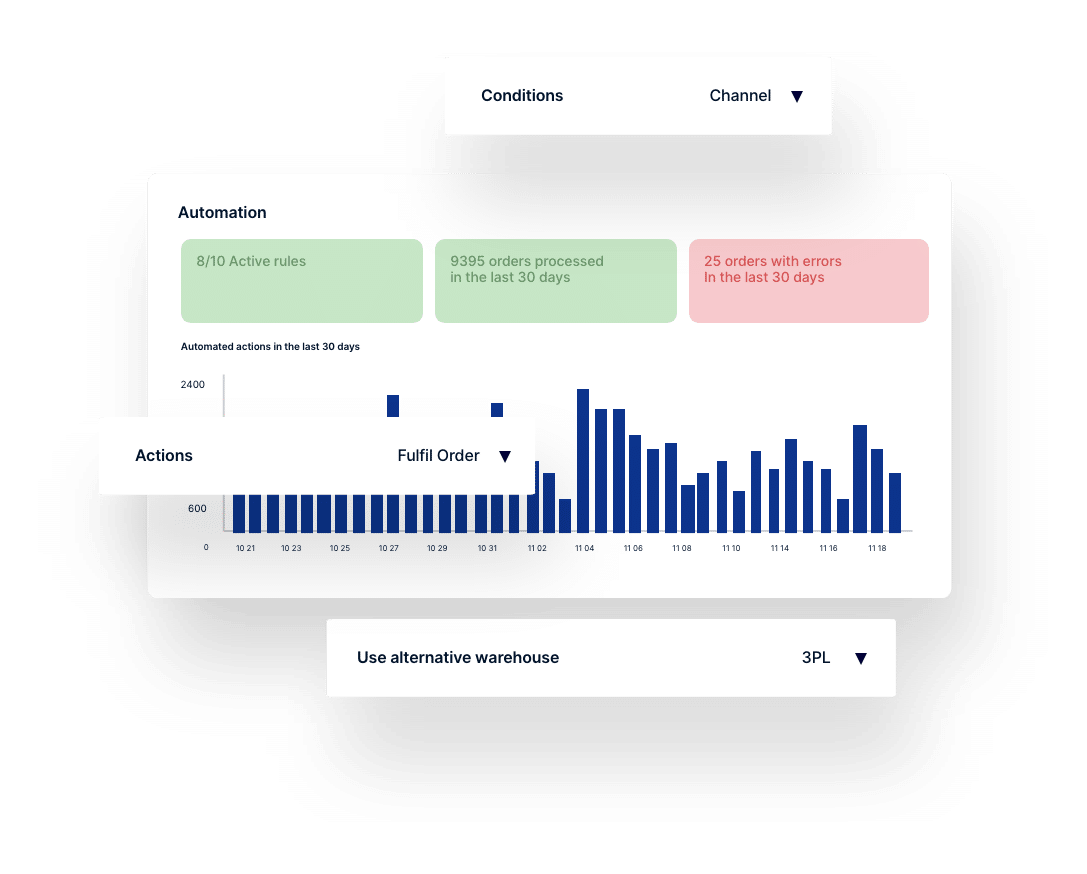

Brightpearl is a comprehensive Retail Operating System that offers advanced pick, pack, and ship capabilities, alongside all the other features you need to run a successful retail or wholesale business. It’s built by industry experts and designed to scale with your company.

Brightpearl incorporates order fulfillment and a warehouse management system alongside inventory management, demand forecasting, and business intelligence. As well as built-in accounting and CRM, the suite of Plug & Play integrations gives you a fully adjustable tech stack.

The powerful Automation Engine optimizes your workflows and processes orders up to 70% faster, with barcode scanning, batching, and auto-generated shipping labels and pick/pack lists. It reduces human error by 65%, cuts shipping time by 92%, and lowers labor costs by 50%.

You can set up dropshipping, partial fulfillment, or channel-specific shipping, and manage all your carriers in one place. Every order, shipment, or return is synced with the rest of the system, so you always know where everything is.

The quote-based pricing lets you add unlimited users at no extra charge, and includes top-notch security, 24/7 customer support, and a dedicated Customer Success Manager. Brightpearl is the best choice to streamline your pick, pack, and ship operations.

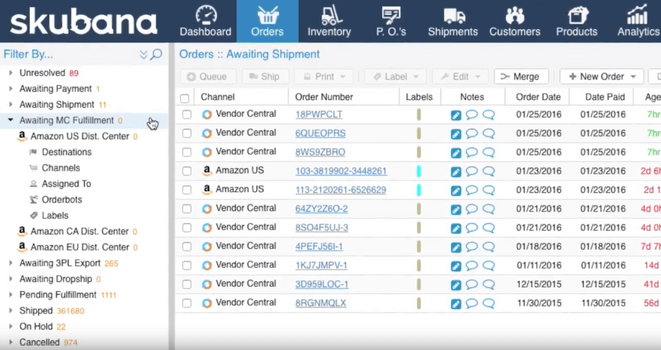

Skubana

Source: capterra.com

Skubana is an all-in-one solution for e-commerce inventory and order management, syncing your data and displaying it on one dashboard. Automated tools include an Orderbot, which automatically applies routing directions and pick, pack, ship instructions.

The system can handle bundling and order splitting, and also comes with predictive analytics, a shipping rates calculator, and plenty of integrations. However, it doesn’t have built-in accounting or CRM, nor multi-currency support.

There’s limited customer support (Eastern time zone hours only). Pricing starts at $1,000 for up to 1,000 orders/month, but you’ll get an individual quote based on things like workflow complexity.

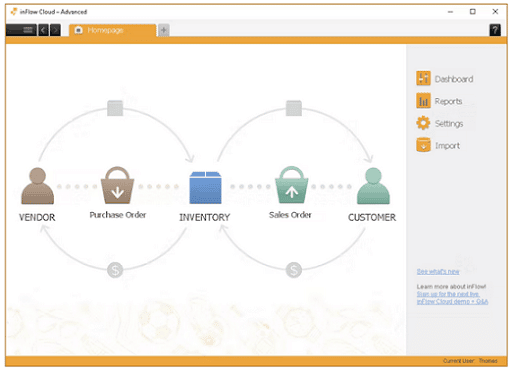

inFlow

Source: capterra.com

inFlow describes itself as inventory management software, but it does have fulfillment capabilities too. Picked products are automatically deducted from your inventory, and you can buy and print shipping labels within the app. Partial shipments are accommodated.

Use a smartphone to fulfill orders and update inventory, or use the inFlow Smart Scanner—for an additional $999! The system lets you browse carrier rates, track freight costs, and generate reports, and there’s unlimited support on all plans.

InFlow has four pricing bands, starting at $75/month for 100 sales orders. You’ll need the third pricing tier to get unlimited integrations—and you have to pay for extra team members and access to API.

Power Ups and Integrations

Here, we’ve identified a few integrations that will help to power up your pick, pack and ship operations.

Carrier integration

As mentioned within the Pack stage above, Brightpearl can be integrated with your chosen carrier to remove the need for manually typing addresses and order weights into their software or websites.

Once you hit around 50 orders a day, even the most efficient member of staff will be spending an hour managing this, and that’s assuming no mistakes! There’s a range of apps that do just this for you, but our top recommendations are ShipStation for the US & Canada, and Shiptheory for the UK. Integrating these systems with your pack services can save time and cut down on errors.

Channel branding

If you’re selling under multiple brands, or even just on multiple channels, you can setup individual packing note templates per channel to customize your messaging. This is particularly useful for chasing feedback from channels such as eBay or Amazon, without cluttering the stationery for your webstore orders.

Warehouse management systems (WMS)

Using scanners as part of your warehousing setup? Great, it’s the way forward; it cuts down on mistakes whilst speeding everything up. Our integrated warehouse management system enables you to easily scan barcodes when picking, packing and shipping orders, and when performing inventory counts. Find out more about our WMS here.

Conclusion

So that covers the recommended workflow of getting items out of the door through our Pick, Pack and Ship process. This is a core area of Brightpearl, and should also be priority functionality within any back office or ERP solution you decide to implement. With pick, pack, ship best practice, you’ll be able to fulfill every order on time.