What is inventory management?

If you’re in the process of just starting out in retail or wholesale, you may be asking yourself “What is inventory management?” or “What is inventory control?”

Effective inventory management and inventory control are one in the same – and the definition is pretty simple to understand.

Inventory management refers to the process by which you track the amount of product you have on your warehouse shelf, in store or sitting with other retailers and distributors. This ensures that your inventory levels are always up-to-date for order fulfillment.

When effectively tracking and controlling your physical inventory, you’ll know how many of each item you have, when you might be running low on products and whether you should replenish that item in order to keep selling it.

What is an Inventory Management System?

You’ve now got an overview of the basics of inventory management and how they’re part and parcel of your day-to-day operations. It’s all about tracking stock, supplies, and sales. In short, everything that impacts the resources you have at hand.

Inventory management systems are your means of organizing all the elements that go into inventory management. It’s the process by which you track goods from one end to the other along your supply chain. Ensuring throughout that you know what you have, where it is, and how to manage it.

There are many types of solutions. No one option will suit every business. Each organization has its own needs and principals. In general, though, automated inventory systems fall into two categories:

- Periodic Inventory Management Systems

- Perpetual Inventory Management Systems

Periodic inventory management systems

This is what is probably best termed as ‘old-fashioned’ inventory management. In fact, the name ‘stock-taking’ is perhaps a better descriptor. Companies count their stock at consistent but comparatively long intervals.

A typical periodic system might see a firm perform a stock take every three or six months. At that time, staff will check warehouses or storerooms, and count the units of inventory on hand. They will typically also calculate the financial value of the stock, as well as raw materials on-site.

At the point of each stocktake, an organization can check that inventory levels make sense. Any decrease in inventory would need to match up with sales figures or wastage. This is the only way to spot any discrepancies that could be damaging to the bottom line.

Periodic inventory management is far from ideal. It’s generally only suitable for the smallest of retailers. It’s only firms that hold and sell minimal volumes of inventory that can get away with a periodic approach. For other firms, such an approach makes it far too easy for costly errors to arise regularly.

Failing to track stock continually, for instance, can allow either overstocking or understocking. Both of these occurrences are hugely damaging to a business. Overstocking means you have valuable inventory sitting idle. You’re also wasting critical warehousing space on that slow-moving stock.

Understocking is just as detrimental to operations. When you don’t have enough inventory, you must refuse orders, or worse, fail to fulfill all the orders you do accept. Having to take either of those avenues will hurt your reputation with customers.

There are also financial and reporting downsides to choosing periodic inventory management. This handy guide to inventory management and accounting can teach you all you need to know for both periodic and perpetual systems. Speaking of which.

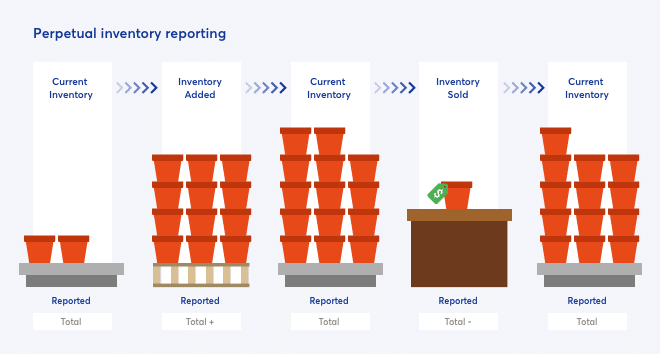

Perpetual inventory management systems

The other principal type of inventory tracking solutions are the perpetual variety. With perpetual systems, everything related to a firm’s inventory and supply chain gets tracked in real-time. Stock levels and associated reports get updated with every sale, delivery, or breakage.

Most retailers use a perpetual inventory management system of some kind. These systems have a raft of advantages over the periodic alternative. In general, perpetual systems allow a higher level of accuracy. That makes for better-informed future planning.

Types of Inventory Management System

Different types of systems are available to help you manage inventory based on your current needs. Here are the major types of inventory management systems or alternatives.

How to Choose Inventory Management System

For fast-growing retailers, selecting an inventory management system entails more than just streamlining current operations. It’s crucial to choose a solution that can effectively handle the increasing complexities that come with business expansion.

In this section, we will outline the key components of a scalable inventory management system, allowing you to evaluate any system under consideration and ensure it meets your evolving needs.

Workflows of Inventory Management Systems

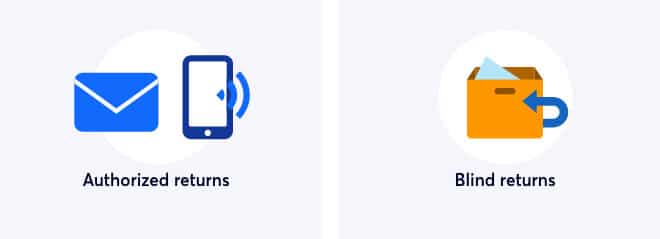

Inventory management systems help you take care of lots of workflows. The exact nature of those workflows depend on how you’re using your inventory management system, and they’ll vary depending on whether your software is designed for things like multichannel inventory management.

We’re now going to take a closer look at four of the most important workflows that are handled by just about any inventory management system:

11 Benefits of effective inventory management

Keeping track of your inventory is fundamental to your success in retail. At the most basic level, after all, your job is to supply the products to meet consumer demand. You can’t do that without effective inventory management.

Listed on the right are the top eleven benefits of effective inventory management that choosing the right system, as detailed above, can deliver your business. They all combine to explain the importance of accurate real-time tracking of stock, and can be easily achieved by using dedicated inventory management software.

Best Inventory Management Systems

For those of you wondering which is the best inventory management system, we’ve compiled a list of five solid choices you might consider.

We would be remiss not to mention that Brightpearl is our top pick for scaling retail and wholesale businesses. It’s the only built-for-retail operating system designed to streamline and automate inventory management, order management, inventory forecasting and purchasing, warehouse operations, accounting, and reporting.

If Brightpearl is not the right solution for you, though, we’ve also selected other systems that will work for different types of businesses at various growth stages.

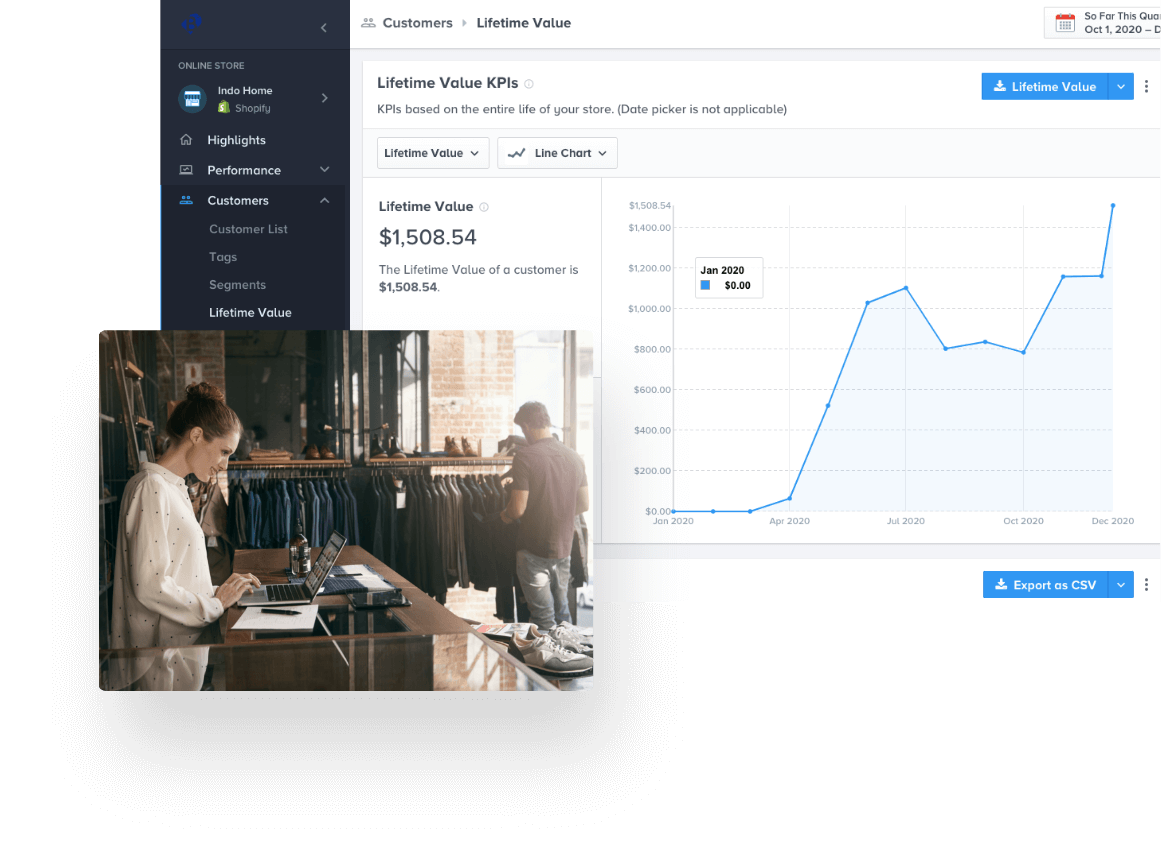

Brightpearl: Retail Operating System for advanced inventory management and beyond

Brightpearl that is designed to handle complex retail operations, from inventory and order management to accounting and retail analytics. Here are the key benefits.

Other Top Inventory Management Systems

What is a retail Inventory Management System?

- A robust, native e-commerce integration, for example, is a must-have if you’re running an online store. Your system should be able to integrate seamlessly with popular e-commerce platforms like Shopify, Amazon, and Etsy, among others.

- If you’re also running a brick-and-mortar store, you need a system that can connect with your POS system. This will ensure that your orders and inventory are synced seamlessly across all channels. Integrated, automated inventory planning is also a must-have. It simplifies inventory planning and purchasing and allows you to make data-driven decisions about when to restock and how much inventory to purchase.

- Automated order fulfillment is also an essential feature that will help you avoid errors and streamline your operations. It allows you to allocate inventory and fulfill orders with minimal intervention, saving you time and reducing operational costs.

Integrating an Inventory Management System with your retail tech stack

We’ve touched upon the importance of integration a couple of times already. Standalone systems – for any business process or area – are not the way forward. At least not for the majority of businesses. Having disparate solutions leads to data silos. They put up barriers to your firm working as efficiently as possible.

There is a raft of options when it comes to software and tech tools to support your business. This retail tech stack report should give you some insight. When choosing any addition to your retail tech stack, ease of integration should be a key concern.

Fortunately, it’s straightforward to unify inventory management systems with your other solutions. The best systems and tools now get built with integration in mind. They boast high-performance integrations with many third-party apps and services. They include examples such as Amazon, Shopify, and more.

The highest-end solutions, too, are comprehensive retail platforms. They don’t only provide dedicated inventory management; they offer that function and more. They can streamline warehousing, back office, accounting, and plenty of other vital processes.

What’s the cost of an Inventory Management System?

The cost of inventory management systems varies depending on the specific system in question. Most systems will charge on a monthly basis, though some offer discounts if you pay an annual fee rather than a monthly one.

Another matter that complicates the cost of an inventory management system is the fact that each user’s needs are unique. That means that anyone using an inventory management system will have different requirements for it, which in turn can lead to paying for different features. With some providers, those features are priced individually (or in bundles), so it’s difficult to give a straight-up, one-size fits-all answer.

However, this only means that the pricing is flexible.

If you’re interested in discovering how much your ideal inventory management system would cost you, it’s worth getting a quote at Brightpearl. Simply tell us what you need, and we’ll be able to give you a clearer idea of how much you should expect to budget to meet those needs.

Wrapping up; How an Inventory Management System could be vital to your success

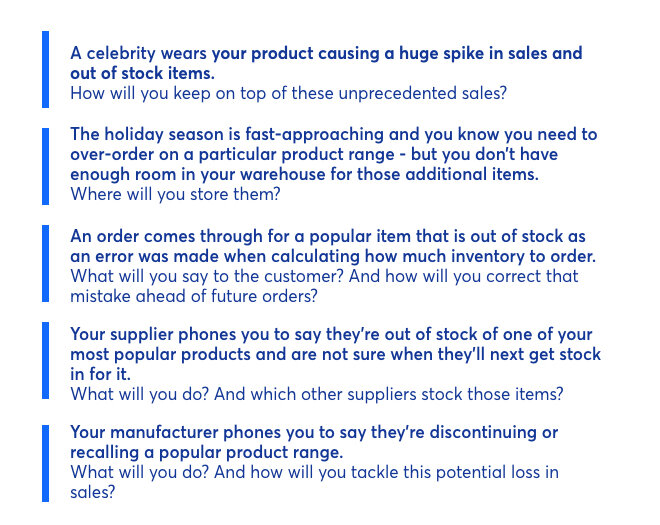

When you boil it down, retail is about having the correct goods to sell at the right time. There are few things more fundamental to the sector, therefore, than inventory management. That’s why you need the right inventory management system to support you in your daily work within the retail sector.

Inventory management systems give you the support you need to ensure your stock is always in the right place at the right time—and that you’ve ordered any item in the right quantity. That’s why excellent inventory management systems like Brightpearl come with a built-in forecasting feature that gives you an accurate idea of the future popularity of any given item in your stock.

In short, inventory management systems are there to make your inventory handling as seamless as possible. This makes them vital to your success.