Effective stock control is essential for any retail business. Without it, you won’t have a clear picture of the goods you have in stock, whether you have too many or too few of them, and when’s best to order replenishments. And this lack of visibility will quickly lead to serious problems, including unhappy customers.

That’s why you need warehouse stock control software, to help you keep track of your inventory and make the best use of your resources. Whether you have one warehouse or a whole network, the efficiency of your stock control processes will have an impact on the wider supply chain as well as the profitability of your own business.

But what’s the best software to choose? In this post, we’ll take a deep dive into warehouse stock control and find out why it’s important to pick a solution with full functionality for inventory management and more besides (such as Brightpearl).

What is warehouse stock control software?

First, let’s recap on what stock control (or inventory control) actually means. The term is often used interchangeably with stock management (or inventory management), despite them being two different things—but they are very much connected and you wouldn’t really have one without the other.

Stock control typically covers the time when products are in stock at your warehouse, whereas inventory management is broader in its scope, encompassing the adjoining parts of the supply chain and the business processes that take place both before and after the warehousing stage.

There’s plenty of crossover between the two, and both are crucial in keeping the supply chain running smoothly. That’s why you need the right software to organize and streamline your processes, tracking inventory at each stage of its journey through the warehouse (and beyond).

Inventory management features are often found as a module within a wider software solution, such as warehouse management software, an ERP like NetSuite, or a Supply Chain Management (SCM) system. There’s also standalone stock control software such as Fishbowl Inventory or Zoho Inventory, while some accounting systems come with an inventory control function.

Whichever one you use, it has to work seamlessly with your other back-end business functions, such as order management, fulfillment and shipping, customer service, and supplier management. Data needs to sync instantly between all the modules or systems, which is why you’re better off with a comprehensive retail operating system like Brightpearl, where everything is in one platform.

Why is warehouse stock control software important?

If your business is going to remain in control of its warehouse inventory, it’s essential that you use stock control software. Even for a small business, manual processes are time-consuming and prone to human error. So, it’s time to scrap the spreadsheets and move into the 21st century.

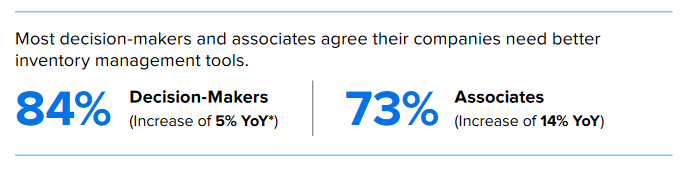

Source: zebra.com

Stock control software vastly reduces your reliance on manual inventory updates, giving you increased accuracy and visibility of your inventory. This helps you to avoid problems like stockouts (which lead to missed sales and unhappy customers), missing or damaged items, or hefty storage costs for excess stock.

The software often includes automated tools for optimization of your workflows, such as barcode scanners that make it easy to locate items and carry out audits. You can categorize products by type, location and SKU (or serial number), generate reports in real-time, and search, filter, and view products. The ability to carry out these tasks quickly and accurately helps you avoid delays in the rest of the supply chain.

It also helps you reduce labor costs thanks to improved productivity, while cloud-based software is significantly more cost-effective than traditional on-premises solutions. It’s highly scalable and allows everyone to access the same system and real-time information from anywhere, on any connected device.

The best software not only addresses the challenges of stock control, but also gives you a strong foundation on which to expand your business with multiple sales channels and locations. For example, it might come with a business analytics feature to help you make smarter decisions, by gathering data from purchases, shipping, storage, turnover, and customer feedback.

If you choose the right stock control software, it will integrate smoothly with your order fulfillment processes, Warehouse Management System (WMS), Point of Sale (POS) app, and e-commerce platforms like Amazon and Shopify. It’s even better if it can sync with other software via APIs or plug and play integrations, too.

Advantages of warehouse stock control software

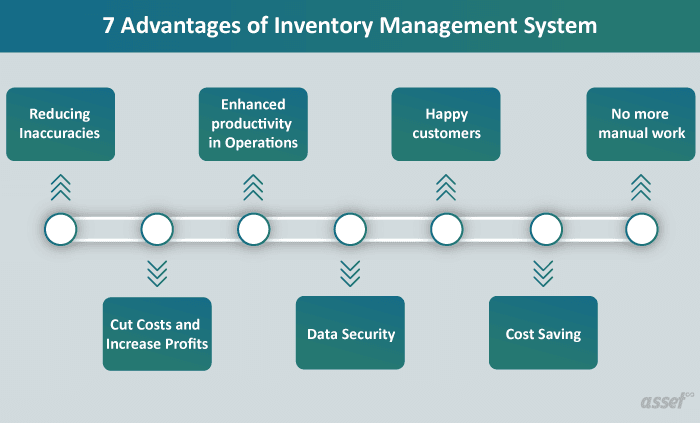

Source: assetinfinity.com

There are many benefits of using stock control software, and the improved efficiency means you should see a fast return on your investment. Here’s why:

Reduced cost

Using warehouse stock control software will reduce your costs almost immediately. For one thing, it’ll minimize the errors that have been costing you money—such as ordering more stock than you actually need. With a clear view of your inventory levels, you’ll be able to identify the optimum times to reorder. This means you’re less likely to get stuck with dead or obsolete stock that you can’t sell (and have to pay to dispose of or recycle).

You could even go one stage further and switch to the just-in-time inventory model—also called lean inventory—where you only order stock just as it’s required and keep as little as possible on hand. This model only works effectively if you can track inventory levels closely, but it means you don’t have to pay so much for warehouse storage space, employees to handle the goods, or insurance.

There’s another potential cost saving that comes from increased accuracy and visibility. Customers are less likely to receive wrong or damaged items caused by a lack of quality control, so you won’t end up sending replacements. Nor will you have to compensate customers for late deliveries due to problems with stock availability.

Increased visibility helps you organize workflows and staff more efficiently in order to reduce labor costs, while automation does the same thing by boosting productivity. Plus, with cloud-based software, you get a lower total cost of ownership with all maintenance carried out by the provider.

Stock accuracy and efficiency

The bigger your business, the harder it is to keep tabs on your inventory. In fact, on average, 87% of decision-makers believe that maintaining real-time visibility of stockouts is a significant challenge. But stock control software means you can ensure your records are accurate. It’s easy to see exactly what you have and where it is, even if you operate multiple warehouses.

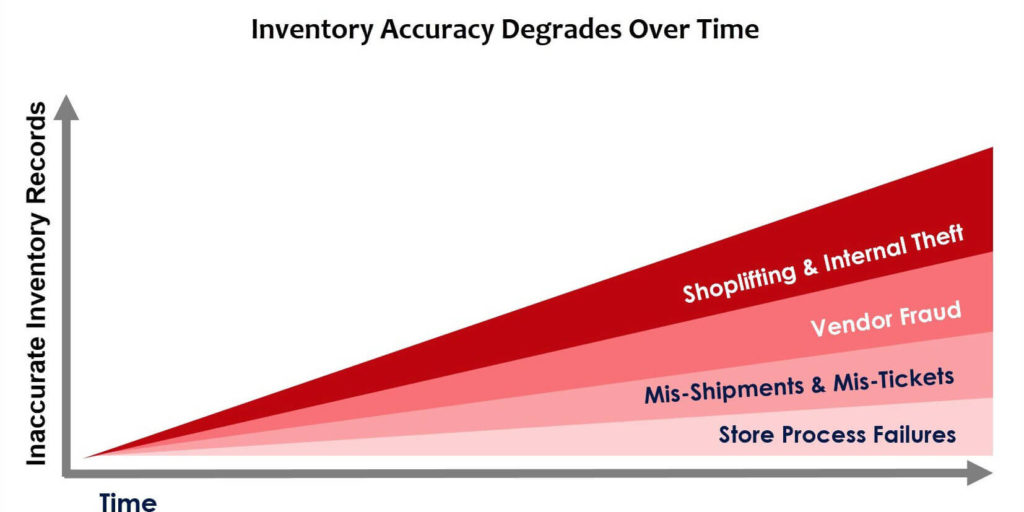

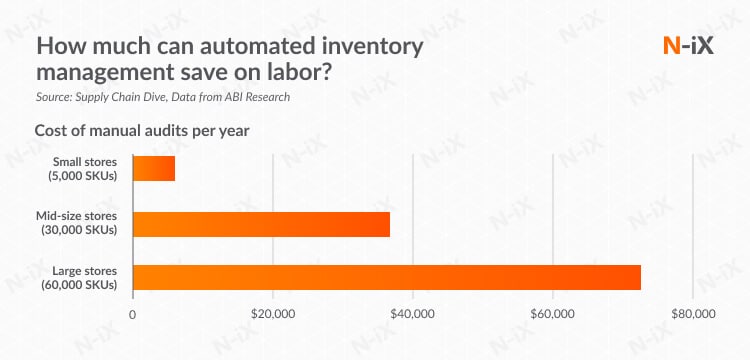

Source: datascan.com

When you have a complete overview of your inventory, it’s also faster and easier to carry out cycle counts and audits, no matter how many SKUs you have. Smart software lets you choose to run stocktakes by warehouse, bin location, or product group. That means the task can be done with minimal disruption to your daily warehouse operations and without hindering productivity.

You can also make the warehouse run more efficiently by organizing goods and workflows based on demand (for example, storing best-sellers close to the loading dock), and setting up rules for FIFO (first-in, first-out) or FEFO (first-expired, first-out) inventory methods. Pickers will always receive accurate instructions because the system is aware of what’s available and where it’s located.

Your software will streamline the process of inspecting and logging received goods. If you receive the wrong amount or the items are damaged, you can reconcile the order, return the shipment, and adjust the amount you pay to the supplier.

Enhanced data visibility and planning

As well as showing you what you have in stock at any given moment, stock control software also helps you to plan ahead. With full inventory visibility, replenishment reports, and product performance analysis, you can decide which products to buy and when is the best time to buy them.

Software with advanced analytics enables you to look out for emerging trends, using both real-time sales information and historical data. You can use this information to make accurate forecasts for future purchases and sales, predict peak times, and ensure you have enough staff and equipment to meet demand.

Business intelligence data from a smart inventory management system is also useful for your marketing team. It helps you identify VIP customers, adjust your marketing efforts to boost conversions, and increase profitability. Your business can remain agile, responding quickly to changing market forces or customer behaviors.

By combining inventory control with financial data from your accounting system, you can check that you are getting the best deals and service from your suppliers and shipping partners, and renegotiate with them if necessary.

Source: fool.com

Better customer service

Effective stock control means you should always have enough goods in the warehouse to meet customer demand. The best software will constantly update your sales channels with the latest information, so shoppers won’t get frustrated by trying to order an item listed as being available, when it’s actually out of stock.

Streamlined workflows will ensure orders are picked and packed ready for loading, so deliveries are more likely to arrive on time. If your software is synced with shipping carriers, you can manage customer relationships by sharing real-time updates on their deliveries. That saves them from having to ask the carrier the question themselves, and relieves the burden on your support team.

Stock control software may also integrate with your CRM (or have built-in CRM functionality, in Brightpearl’s case), which helps you get to know your customers and personalize the service they receive. You might send out gifts, custom delivery notes, or special offers on bundled products or shipping fees.

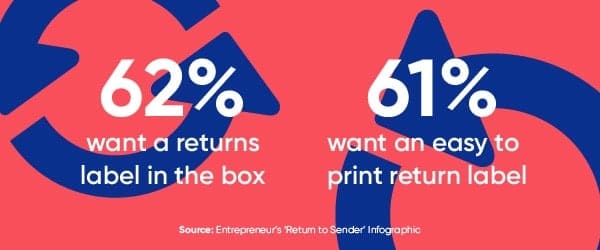

A simple and fair returns policy backed by efficient returns management is another way to keep customers on-side, as is a commitment to data security. Great customer service encourages good reviews and repeat sales.

Save time with automation

Automation is a boon for warehouse inventory control, for businesses of all sizes. It helps you speed up all processes like cycle counting and fulfillment of complex sales orders, using technology such as barcode scanners, RFID tags, and auto-generated pick and pack lists and shipping labels. You can set your own rules and customize workflows to suit your business needs.

By reducing the time spent on manual data entry, the technology ensures that employees can massively increase the number of items scanned, counted, picked, and packed on a single shift. This frees up resources so your staff can spend time on more complex tasks and you can save money by operating a smaller workforce.

It’s worth noting that advanced automation is only available with the top software—such as Brightpearl, which has an Automation Engine that can save you a ton of time (and money).

Source: n-ix.com

Good coordination across different locations

For a growing business, expansion is essential. Operating warehouses in multiple locations has the advantages of extra storage capacity and lowering transportation costs, while multichannel selling offers convenience to shoppers. But it’s harder to coordinate—unless you have the right stock control software!

It’s vital that you have a full view of all your warehouses and stores, so that you can see at a glance which items are currently in which location, and accurately reflect stock availability on your e-commerce platforms. This includes managing logistics for virtual inventory, dropshipping, or consignment inventory that’s stored away from your premises.

Stock control software makes it easy to coordinate all your locations and channels in one place. For example, Brightpearl syncs and updates the data whenever there’s a change to inventory levels. With cloud-based solutions, all users enjoy secure access and real-time collaboration across locations.

Features to consider when choosing your warehouse stock control software

Each stock control software alternative has different features and capabilities, so it’s important to do your research and find the right one for your specific needs.

Prices vary, too, so look for value for money based on your challenges and goals. Larger businesses will need advanced tools that can handle high order volume and complexity, while smaller organizations will want a scalable solution. Swift implementation and general ease of use are also important.

Here’s some fundamental features to look out for:

Real-time inventory tracking

This is a crucial requirement of any inventory management software. You need to see any changes to stock levels in real-time. It’s no good if the system takes five minutes to update when an item’s been sold, because in those five minutes a customer may have placed an order for that same item on another channel, and you only have one in stock.

It’s also important that you’re able to see where items are within the warehouse—are they in the receiving area, at pick and pack stations, or on the loading dock? The central system should update each time an item is scanned, so you have a clear idea of how long the order process is taking. Real-time information makes it much easier to do a quick inventory count.

If your software integrates with other back-end systems, you can also track goods while they’re en route from the supplier, being transferred between warehouses, on trucks bound for customers, or in the returns pipeline. It’s also helpful to track the real-time value of your stock, and get a live view of profit margins by channel, product, location.

Barcoding

Barcoding is a method of tracking goods electronically. The system generates an adhesive label for each item, containing basic information like name, SKU, and manufacturer. This enables it to be read by a hand-held barcode scanner, using a beam of light to read the black and white pattern.

Barcodes are scanned whenever items are received, stored, transferred, processed, and shipped, which instantly updates the central system so that everyone can see the current status or location. Collecting, storing, and organizing this inventory data makes all your operations faster, especially as the scanners are so easy to use.

It also improves accuracy. There are no errors caused by manual data entry, and you can ensure that all items are in their rightful places. Barcoding makes goods on shelves or pallets much easier to locate for cycle counting, sorting for cross-docking, and picking (including bundled orders or kitting).

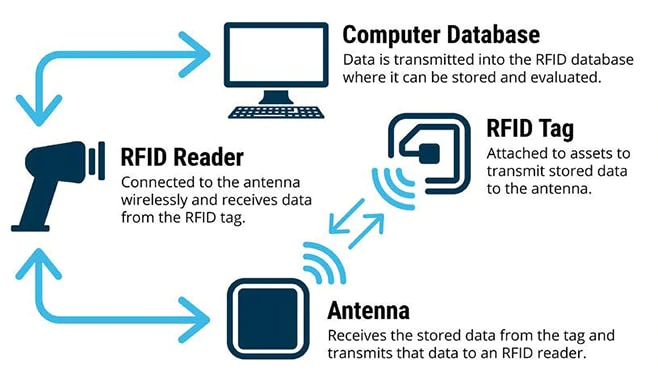

Tagging

Tagging is similar to barcoding, except that the tags are digital, and are read by RFID (radio frequency identification) devices that use radio waves to identify the chip in the tag and transmit the data. Tags also include extra details such as product maintenance information and expiry dates, and this data can be added to, whereas barcodes are read-only.

Source: shopify.com

This method allows you to scan multiple tags at once for speed. RFID allows you to track each individual item, even those with the same SKU, so you can avoid scanning the same thing twice. The almost-total accuracy eliminates the need for work to be double-checked.

Tags don’t have to be visible to the scanner either, they can be embedded in the packaging or within the item itself. Some tags even contain sensors for temperature or humidity, while “active” tags run on batteries and emit a ping every few seconds, guiding any reader in the area to their location instead of waiting to be scanned.

Both barcodes and tags are a great way to save time and reduce errors. Plus, 70% of associates feel more positive about their employers when they provide them with useful technology.

Inventory forecasting

Your stock control software needs to incorporate forecasting capabilities, and the more advanced the better. With accurate planning, you’ll be confident that you’ve ordered the right amounts of stock at the right times, avoiding the perils of carrying too much or too little. This way, you can reduce waste and holding costs, while keeping customers satisfied.

An analytics feature is required so that you can keep an eye on product performance and look out for changes in the market that will inform your purchasing. When your software is synced with other parts of the supply chain, you’ll get early warnings if there is a delay with product manufacturing or delivery. That means you can make alternative arrangements to meet demand. You can also use inventory forecasting to boost your sales and marketing efforts.

Inventory alerts

Even with a smart software solution, there’s still the possibility that you could experience a hitch in your warehouse stock control process. But with inventory alerts, you don’t even have to remember to check the central system—you’ll be kept informed of critical changes via SMS or email.

Using your available data, you set an appropriate reorder point (the optimum moment at which to replenish your inventory to avoid a stockout). The system will then notify you when stock is about to reach this level, providing a reorder report of all the items that are running low.

You can then quickly generate a purchase order, or program the software to do this for you. Brightpearl will automatically choose the most cost-effective supplier and place the order based on your predetermined settings. You might also want to receive alerts about order status, which you can pass on to customers.

Purchase management

Stock control software should help you stay in control of your purchasing. It goes without saying that when you have full visibility into the location, amount, and value of your stock, you’ll find it much simpler to figure out how much you need to buy and from which suppliers.

With automation, there’s no need to manually transfer your inventory data or supplier details into your purchasing process. You can generate and autofill your purchase orders as well as invoices, and sync the whole process with your accounting system.

If you have all your supplier details housed in one place, it’s easy to view your transaction history and communicate effectively for the best deals and relationships. You can also schedule inventory for arrival at the most suitable times based on your available labor, equipment, and storage space.

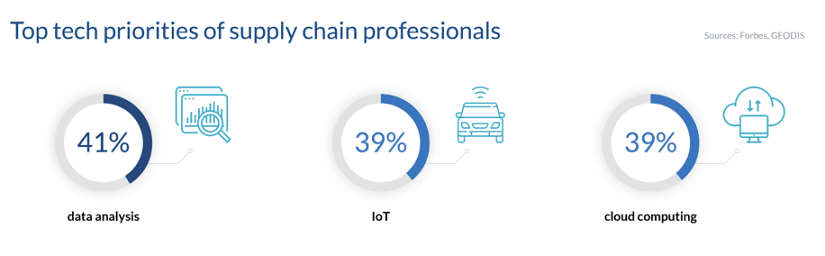

IoT integration

IoT, or the Internet of Things, is a network of objects connected to the internet that use built-in sensors to collect and exchange data. The global IoT market size is expected to reach $875 billion by 2025, at a CAGR of 26.9%, and the technology has obvious applications for warehouse stock control.

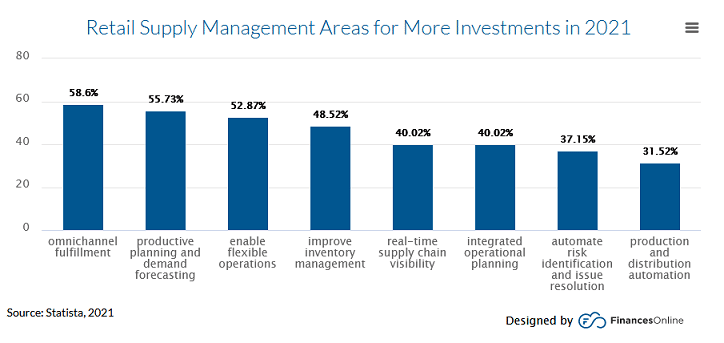

Source: financesonline.com

With hand-held mobile devices such as barcode and RFID scanners, mobile apps for iOS or Android, and wearable tech, employees can move around the warehouse and still be connected to the central system. This enables real-time tracking and instant inventory alerts. And in your physical stores, a POS shows real-time stock availability in all locations and automates backorders.

IoT tech also includes smart sensors in the warehouse and in packages, which can monitor conditions such as temperature, time spent on shelves, or time in transit. This is ideal for perishable goods, and also helps with tracking delivery drivers. And IoT connectivity also helps to improve security against theft and loss.

Inventory reporting

As well as displaying real-time and historical data on a central dashboard where everyone can access it, your stock control software should also generate inventory reports. These may include data on current stock levels, inventory turnover rate, backorder rate, stock age, and profit margins. You could ask the system to report on predicted demand and staff performance, or create a list of product weights and dimensions for shipping.

Reports should be simple to understand, using charts and graphs alongside the numbers. They can help you to see the big picture or drill down into a certain aspect of stock control, meaning you can make faster business decisions and spend resources wisely. For example, Brightpearl’s product performance analysis shows you which lines are popular and which you might want to ditch.

Brightpearl’s warehouse stock control software

So, we’ve shown you the key features to look out for—now let’s take a look at how Brightpearl checks all the boxes.

Benefits of working with Brightpearl

Brightpearl is a retail operating system that gives you a set of advanced tools in one place—not just stock control, but also warehouse management, order management, shipping and fulfillment, purchase and supplier management, business intelligence, accounting, and CRM.

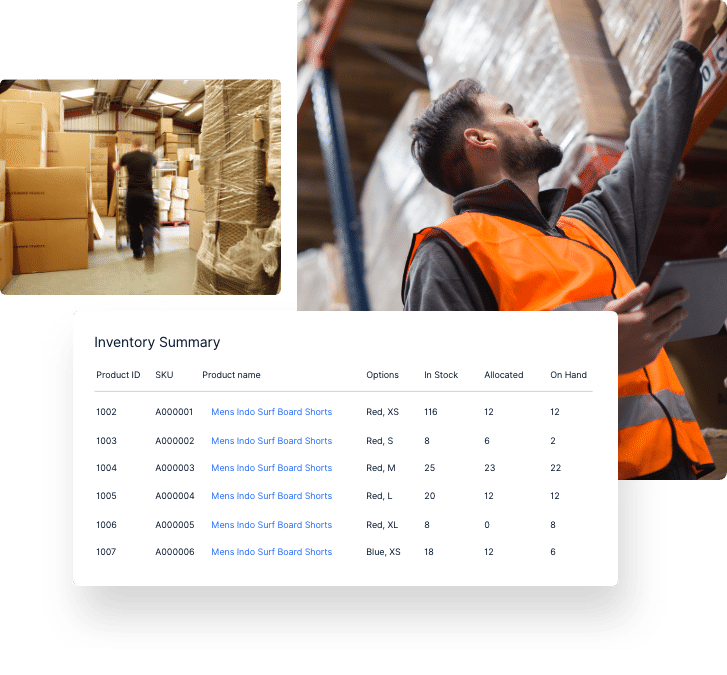

This gives you a real-time overview of inventory levels across locations and channels, with handy dashboards that highlight things like stock on hand, items on purchase, items that need to be reordered, and the most overstocked items.

Brightpearl is specifically built for retail and wholesale e-commerce businesses, so the features are designed for your needs. And the implementation, training, and 24/7 support is delivered by retail experts. The Grow Fearlessly ethos means the system is highly scalable, with no limit on the number of users (or products, suppliers, and locations) you can add.

Scalability is also assured with the plug and play integrations, enabling you to switch up your tech stack as you grow. The native connectors are super-fast and minimize glitches and delays in data exchange between different systems and platforms. Brightpearl is a certified partner of Shopify and Shopify Plus, BigCommerce, and other e-commerce platforms.

Brightpearl’s cloud-based and leased on a monthly subscription, giving you a lower total cost of ownership and accessibility from anywhere. The system is easy to deploy and to use, but robust enough to cope with high order volume and complex orders (thanks to the powerful Automation Engine).

Features of Brightpearl to help with warehouse stock control

Real-time visibility

Brightpearl gives you instant, automatic inventory updates across all your e-commerce platforms, marketplaces, and physical stores. This happens after any new order, replenishment, return, or warehouse transfer. If you’re selling on Amazon, you can reconcile inventory directly in Brightpearl when stock fluctuations occur.

You can make full or partial cycle counts based on criteria like product performance, item value, and location, and even track raw material inventory for the bill of materials. Barcode scanning and audio alerts for pickers help to ensure speed and accuracy.

Replenishment

With replenishment reports based on your sales history and various forecasting metrics, you can quickly see the types and quantities of products that need to be reordered.

The system factors in fluctuations like seasonality, out of stock periods, and promotions, and lets you create purchase orders in one click, directly from the replenishment report. You can even automatically specify which suppliers to order with when you hit the reorder point, and the date you want items to be received.

POS

Brightpearl’s built-in POS syncs inventory, orders, and customer information between your online and offline sales channels, so you always have an accurate picture of stock availability (and product details) in order to avoid overselling. It also lets customers browse and order products that aren’t currently in stock—you can automatically fulfill orders from external warehouses or mark items to be back-ordered.

Automation Engine

As we mentioned earlier, only the most advanced stock control software gives you full automation (and Brightpearl does a lot more besides stock control). The Automation Engine allows you to set up customized rules to automate time-consuming tasks, from inventory allocation and order fulfillment to shipping and accounting.

You can automatically allocate orders to different warehouses based on stock level, destination, and order contents, and transfer inventory between locations—including partial transfers when not all the items in an order are available from one place.

Product performance analysis

By analyzing product performance data across all your sales channels, you can make smarter decisions on purchasing. Brightpearl makes it easy to identify your best and worst sellers based on metrics such as order volume, revenue, margin, or customer lifetime value and view product data by channel, ad platform, geography, customer segment, or seasonality.

Once you spot the products that are selling slowly and taking up valuable space in your warehouse, you can discount or liquidate them to free up cash and reinvest it in more profitable lines.

Demand forecasting

Brightpearl’s integrated Inventory Planner provides data-driven forecasting and replenishment recommendations, using metrics chosen by you to reflect your business goals. You can compare real-time and historical data to see how your inventory is performing over time, and spot emerging trends and opportunities.

The open-to-buy reporting feature helps you figure out how much inventory to buy on a monthly basis, and allocate corresponding budgets for vendors, categories, and brands to meet sales projections.

Returns management

Returns can be a logistical nightmare for businesses, but customers expect the process to be simple and affordable (if not free). Brightpearl takes the stress out of the return and refund process for both customers and employees, by automatically initiating the sales credit process as soon as the returned items are received in the warehouse. It’s also easy to reconcile deliveries and returns.

Retail accounting

In Brightpearl, financial and inventory management work seamlessly together, whether you use the built-in retail accounting feature or the integrations with Xero and QuickBooks. With all the data in one central hub, you’ll gain real-time insight into sales performance, profitability, and costs across all channels.

You can also understand the true value of your inventory with FIFO (first-in, first-out) inventory valuation, automatic product cost calculations, and accurate landed-cost reporting for overseas sales. Meanwhile, the ability to generate batch invoicing also saves a ton of time.

Supplier management

Another advantage to using an all-in-one platform for stock control is that you can manage all your suppliers in one place. That means it’s easy to keep track of all activities, including communications, orders, and payments due.

You can view a complete audit log of your supplier contact records, and even provide suppliers with access to a web portal to eliminate manual tracking and data entry.

Final thoughts

As we’ve seen, effective management of your stock is crucial to the smooth running of your business and the success of the entire supply chain. With the right inventory management solution, you can save time and money, avoid the pitfalls of stockouts or excess stock, and improve the experience for customers and warehouse staff alike.

Stock control tools work best when they’re paired with other business systems, like warehouse management solutions, order fulfillment, shipping, and accounting. You should make sure your chosen software is flexible and scalable so that you adjust and expand your operations over time without compromising on control.

Brightpearl gives you all that and more—it’s the complete package for retail operations. For more information, visit the website and request a demo or a chat.