If you’re a multichannel retailer, wholesaler, or e-commerce brand, keeping on top of inventory control can be a daunting prospect. Systems, processes, and technology are now available, though, to help companies streamline their supply chain. With the use of inventory control systems, you can efficiently and accurately track your merchandise.

This guide will help you with explanations of what inventory control is, clear inventory control meaning examples, different types of inventory control, and the its importance, and its and challenges of inventory control systems. It will also provide tips for inventory control, discuss some inventory control systems and techniques, and answer the question “What does inventory control do?”.

What is inventory control?

Inventory control, also called stock control, is the process of managing a company’s inventory levels, whether that be in their own warehouse or spread over other locations. It comprises management of items from the time you have them in stock to their final destination (ideally to customers) or disposal (not ideal). An inventory control system also monitors their movement, usage, and storage.

Inventory control means managing your inventory levels to ensure that you are keeping the optimal amount of each product. Proper inventory control can keep track of your purchase orders and keep a functional supply chain. Systems can be put in place to help with forecasting and allow you to set reorder points, too.

Inventory control can include:

- Barcode scanner integration

- Complete inventory counts

- Keeping track of physical inventory with sales and purchase orders

- Product details, locations, and histories

- Reports and adjustments

The general goal is to maximize your profits while the least amount of inventory possible is sitting in your warehouse. Your business must do this without compromising customer satisfaction. While you can handle inventory control manually, there are automated systems that take the responsibility of managing your stock levels, and help eliminate costly human error.

According to the US Census Bureau, in July 2020, U.S. manufacturers and retailers were holding $1.33 of inventory for every $1 in sales. Effective Inventory control allows you to change that inventory/sales ratio for the better. Stationary stock does not do anything for your business or its bottom line. Make the most out of the precious space you have, while ensuring you always meet customer demand.

Difference between inventory control and inventory management

Inventory control focuses on the products already in the warehouse. It involves tracking item locations, maintaining product quality, and organizing inventory to minimize costs. By ensuring items are stored correctly and remain in good condition, inventory control helps keep operations efficient.

On the other hand, inventory management takes a broader view. It includes forecasting demand, planning product replenishment, and deciding when and how much to reorder to avoid stockouts or overstocking. Effective inventory management ensures the right products are available at the right time and in the correct quantities. Improving inventory control ultimately strengthens overall inventory management.

Why is Inventory Control important?

Here are some ways inventory control is important for your business so you can gain an inherent understanding of the purpose of inventory control.

Quality control

Having an inventory management system allows you to implement greater quality control. If you can track and manage all aspects of your stock, you better control quality. The longer you hold inventory, the more likely it is to get damaged. You can avoid that by ensuring that stock gets rotated through your warehouse.

Inventory control techniques also allow you to track the quality of stock you receive from suppliers. How often do you have certain products returned? How often are those that are returned sent back because they break or have other defects? Seeing how products move through your inventory can point to any problems, and help you eliminate write-offs.

Organizational control

Inventory control means that you have organizational control in your business. A well-organized stockroom lets you manage your merchandise and make the most of your investment in physical inventory. This aspect of inventory control is vital for knowing where your stock is and the expediency with which you can access it.

Inventory control in terms of the organization of your stock is vital for the proper running of your company. It will ensure that you have enough units to fulfill orders and have safety stock. Effective inventory control techniques will also help you avoid having any dead stock or overstock. Safety stock acts as a buffer to reduce the risk of an item being out of stock. Dead stock is inventory that doesn’t sell. Which explains in a nutshell why inventory control is required.

Accounting accuracy

Keeping an accurate record of your inventory is vital for managing your assets. It will also help you in the event of an audit. Knowing what you have in assets allows you to know your overall spoilage and understand the value of your company.

Financial accounting rules and tax regulations may mandate your company to have a physical inventory account. All stock should have correct numbers and pricing in your inventory systems and your accounting software. This will ensure your company can go through audits without any question to your business’s accounting integrity.

How to control inventory costs effectively

Inventory control software helps to record stock, packing, and shipping information in one place and, therefore, optimizes your business’s procurement process. Real-time updates on stock movements can help you automate control of stock levels for accurate sales performance and inventory analytics. All of that helps you to control inventory costs.

How inventory control improves retail operations

Effective inventory control is more than just tracking stock—it’s a powerful way to optimize operations and drive growth. By maintaining accurate inventory levels, businesses can reduce costs associated with overstocking, storage, and spoilage while ensuring customer satisfaction through timely order fulfillment. Automated systems streamline processes, eliminate manual errors, and provide real-time insights, enabling data-driven decisions that refine purchasing strategies, enhance supplier relationships, and boost overall efficiency.

As businesses scale, robust inventory control ensures smooth operations across expanding product lines and locations. It supports financial accuracy, simplifies audits, and protects profitability by minimizing risks like stockouts and damaged goods. Ultimately, inventory control equips businesses with the tools needed to adapt to market changes, meet customer demands, and achieve long-term success.

Common challenges with inventory control systems

Inventory control is vital for effective business operations. It can also come with challenges. It may seem difficult to find the time and resources, and developing a complete picture of your inventory can be difficult, especially if you have a larger company or multiple inventory locations.

However, these challenges can be overcome to ensure effective control over your inventory. The best way to manage all these challenges is to automate your inventory control process. Look into the best inventory management software for your business.

Below are a few of the challenges you may face.

Resource allocation

Doing inventory management manually requires substantial resources. Money and staff hours are required for manual inventory control. However, if you do not prioritize inventory control, you will lose more time and money later on. Take the time to implement a regular schedule to dedicate to inventory control. Also, make sure to include inventory control in your budget.

Visibility

Companies with large stock, complex warehousing, or that are selling on multiple channels can have many moving parts to their inventories. This can create challenges with visibility. Businesses must have a complete picture of their business’s inventory for replenishment, accounting, cash flow, and sales purposes. Losing sight of your inventory can lead to the degradation of inventory quality and can lead to dead stock. This is why it’s essential to learn how to control warehouse inventory.

The reports you can obtain through inventory control software systems can help you improve visibility. For instance, you can get alerts when inventory level is low Having high visibility on how your inventory moves limits obsolete stock and helps determine how much inventory of each product you keep to meet customer demand.

Human error

Human errors are unavoidable when businesses have a constant flow of inventory in and out of their warehouses. For example, vendors need to send accurate invoices and they need to be matched with purchase orders and physical inventory. Any inaccuracies that occur at this stage can impact your inventory control.

You can mitigate human error by the optimization of your inventory control system and integrating your solutions. This will allow your software to alert you if there are any discrepancies between what was entered in the accounts payable and the physical inventory counts.

Types of Inventory Control Systems

There are a number of types of inventory control systems and related techniques that businesses can utilize. So, what are the types of inventory control that your business needs?

Each has benefits and disadvantages based on your inventory size and company operations. Retailers may find that they have different needs to a wholesaler, for instance. Start by defining your business goals and metrics to get an idea of your current and future needs and pick an ideal inventory control method.

Then, determine if your business should use a:

Spreadsheet to control inventory

The use of a spreadsheet as a manual inventory control technique works best for smaller businesses that don’t keep much stock or have a lot of different kinds of inventory. Keeping a spreadsheet is less expensive than the other two, but inventory control can be harder to maintain. Your team members will not, though, have to spend time learning to use an automated system for inventory control purposes.

While you may feel it gives you a better sense of control, manual inventory control through the use of a spreadsheet is far more prone to human error and is labor-intensive. Supply chain management may also be harder to maintain because it will require an employee to keep track of multiple moving parts. The replenishment of stock will also be harder to track in a manual system.

Periodic inventory system

A periodic inventory system usually relies on physical inventory counts. Inventory information is updated periodically when a physical count is conducted. This type of inventory control system is super time-consuming for businesses that deal with large amounts of inventory or frequent inventory moves. However, inventory control methods like this can work for companies that don’t handle many orders.

Periodic inventory generally uses the formula:

Cost of Goods Sold (COGS) = (Beginning Inventory + Purchases) – Closing Inventory.

This inventory control system is easy to implement and requires minimal information. However, your stock levels will rarely be up to date, leading to delays and increased write-offs. It also relies on inventory audits rather than an automated system that updates in real-time.

Perpetual inventory system

Perpetual inventory systems update your stock in real-time when a transaction happens or new stock is received through technology solutions. Around 72% of all retailers plan to adopt real-time visibility in their supply chain using automation, sensors, and analytics. It allows you to easily implement inventory management techniques like Economic Order Quantity (EOQ). EOQ makes sure inventory meets demands while minimizing holding and storage costs.

Perpetual systems give you better visibility on your inventory than periodic systems. These types of inventory control system functions lower the cost and time spent on physical inventory counts.

Inventory control system examples and use cases

Here are some ways in which robust inventory control will help your business:

- When you’re carrying out an audit, the computer system says there should be 1000 pairs of sunglasses on the shelves, but there are only 980. What happened to the rest? Have they been stolen or did the supplier send the wrong amount? While you investigate, you can update the system to reflect that only 980 pairs are available for sale on your website, so customers aren’t trying to buy something that doesn’t exist.

- While reviewing stock levels, your inventory control manager notices that a particular type of candy bar has been sitting on the shelves for a while, and the expiration date is approaching. Once this is flagged up, the company could decide to sell the items at a discount or bundle them with some other popular candy, to get stocks moving.

- Another example is store inventory control, which specifically involves monitoring stock levels, quality, and availability of products in your physical and e-commerce stores. It’s important that your inventory management software syncs data across channels, so you can easily see if any items are running low or close to expiry. In physical stores, a POS system will instantly tell staff whether or not a certain item is available from another location.

6 Inventory Control Techniques

Inventory control is a complex business. There’s no one way to get it right, and different inventory control techniques will suit different businesses and situations. Here are just a few popular techniques and aspects of inventory control to consider:

JIT (Just in Time)

This technique, pioneered by the Toyota auto company in the 1970s, sees businesses holding the least amount of inventory possible. Rather than buying in advance and keeping the products on your shelves, you only purchase inventory when it’s needed—and the shipment arrives “just in time” to meet demand.

This enables you to operate smaller warehouses (reducing overheads and staff wages), spend less on inventory, and avoid the problems associated with excess stock. However, you also run the risk of a stockout if there are any delays, as you won’t have any safety stock as a backup.

Bulk shipments

Buying and shipping goods in bulk is almost always cheaper, whether you’re ordering them from a supplier or sending them out to your network of warehouses, distribution centers, or stores. When buying products in bulk, you need to be confident they’ll sell, or you’ll end up with excess stock.

This method is best for items with stable demand and long shelf-lives. It means investing more cash upfront, so check that this is offset by the cheaper prices. Bulk shipments may also cost more in terms of container space, but you’ll have fewer shipments to send out.

Dropshipping

Dropshipping is a way of saving money by cutting out the middleman. Instead of receiving goods from a supplier or manufacturer and storing them at your warehouse, you work with a partner (the dropshipper) who delivers orders directly to your customers.

Your business is responsible for processing customer orders and passing the details to the dropshipper, but you never actually see or handle the products you’re selling. This reduces your overheads, but it means you’re not in control of quality or delivery speed. And customers will still complain to you if there’s a problem!

Consignment

Consignment is when you place an order with a supplier and they deliver the goods to you, but you don’t actually pay them until the goods have been sold. In this method, the supplier is referred to as the “consignor” and your business is called the “consignee”.

If you end up not selling the items, you can send them back to the consignor without being charged. It’s a good way to experiment with new product lines when you’re not sure how well they’ll sell, without tying up cash in a large upfront payment. It’s the consignor who bears most of the risk.

Cross-docking

This is another technique that reduces the amount of inventory you hold, or eliminates the need for storage altogether. At a dedicated cross-docking facility, goods arrive from a supplier and are inspected, sorted, and prepared for shipment. They are then loaded on to delivery vehicles and sent out immediately.

If you operate your business entirely on a cross-docking model, you’ll only need a small premises to carry out receiving and reloading. Or you could use this technique only for certain products. For example, items promised for same-day delivery or those with a very short shelf-life.

Cycle counting

Most retailers hate doing full stock takes. They’re tedious, they’re time-consuming, and they divert staff away from other tasks. You might even have to close your physical store for the day. Cycle counting, where you regularly count small amounts of inventory, is much more convenient.

By checking just one type of product at a time, you can verify that the actual stock matches the numbers recorded in your inventory management software. If it doesn’t, you’ll know there’s a problem and you can perform a wider audit. Cycle counting doesn’t mean you never have to do a full stock take—you can just do it less frequently.

7 Inventory Control Best Practices

Now that we have a foundation of what inventory control is and the inventory control systems you can utilize. Here are some tips when it comes to inventory control.

1. Use real-time inventory tracking

The value of automation cannot be understated. Real-time tracking gives you the most accurate, up-to-date information which guides your financial and business decisions. It can help increase your ROI and reduce your carrying costs. Automatic inventory tracking is extremely helpful when selling on multiple channels. Overselling can be damaging to the customer experience but can be avoided when all the orders and inventory information is synced in real-time across all channels.

2. Be consistent with your labeling system

Modern warehouse management gives companies a wide range of options when it comes to labeling and identifying inventory. Find a system that works for your business and then be consistent with label strategies.

For example, SKUs make your inventory easy for your team to manage. Barcoding your inventory allows you easier multi-location inventory control, and multichannel inventory management.

Your company might also use Radio Frequency Identification (RFID) to identify individual products and components. RFID isn’t just for raw materials, it can be used just as effectively with finished stock and can track items throughout the supply chain.

3. ABC Analysis

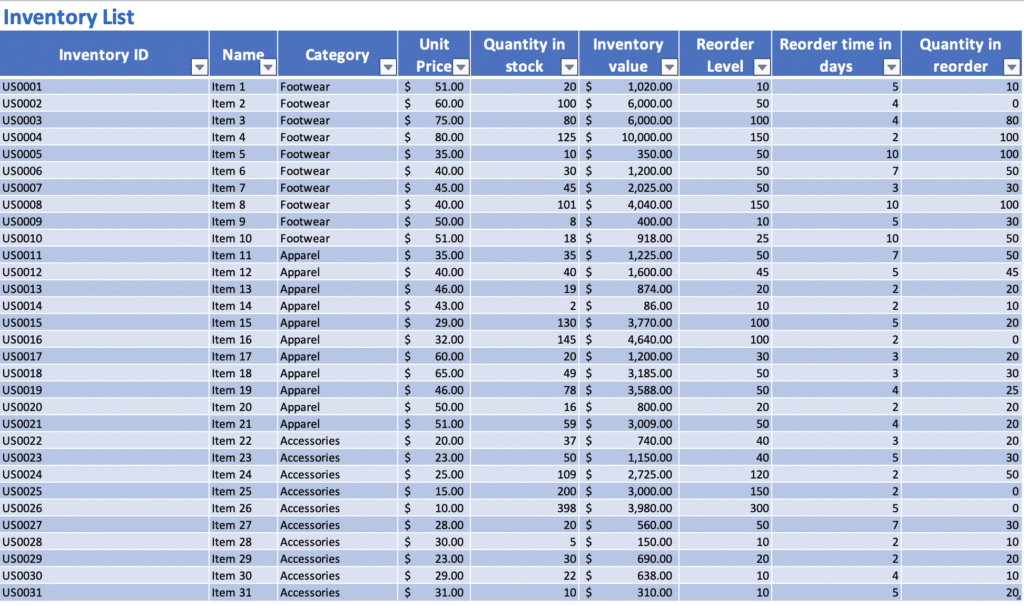

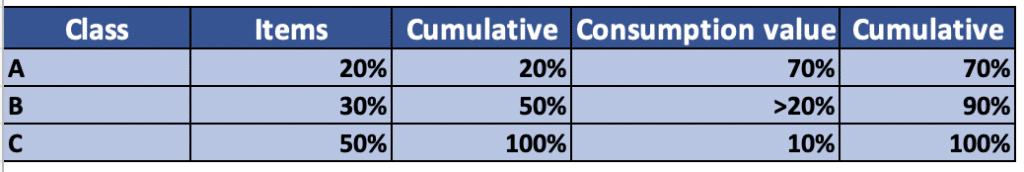

One strategy you can use in a perpetual system is ABC analysis. This classifies inventory items based on the item’s consumption value. That value is the total value of a piece of inventory consumed over a specific time frame. The letters stand for the different categories items can be placed into.

- A items refer to goods with the highest consumption values. This will be a low number of items with a high consumption value.

- B items are the category with less consumption value than A but higher than C items.

- C items have the lowest consumption value. The risk on this stock is low, but so are the returns. They often make up a good portion of your stock.

The table below is an example of how this system would be implemented in practice:

4. Set reorder points

This may seem obvious, but reordering can be a tricky part of inventory control. You want your customers to have quick access to stock without having to deal with the carrying costs of dead stock. With inventory control software, you can set these levels to alert you when a product gets below a certain level. You can set individual products to reorder points using EOQ or ABC analysis.

It can also help you have better control over your lead time. Lead time is the time that passes between when an order is placed to replenish inventory and when it is received. This factor affects the amount of stock you need. Dead stock takes up valuable warehouse space. On average, space in warehouses and distribution centers in the US costs $5.08 per square foot. To enable a more accurate replenishment, you can also adopt a data-driven inventory planning system.

5. Organize your warehouse

It’s imperative that your warehouse is well organized, with all products exactly where they should be and all properly labeled. That way, there’s no time wasted on searching for items, and it’s immediately obvious if something is damaged or missing. Goods should be checked as they arrive, and logged into your computer system.

Automation, such as barcode scanners and auto-generated pick lists and shipping labels, will help streamline your processes, as will an efficient layout. Place best-selling items nearest to the packing station or group products that are frequently ordered together. It’s also crucial to store perishable items correctly.

6. Back-up your data

The only potential problem with a computerized inventory management system is that it could crash, causing you to lose your data. This could be catastrophic for your business—you wouldn’t know how many items had been sold that day, which orders had been fulfilled, or whether new goods had arrived from a supplier.

That’s why it’s vital that you keep your data backed up, and a cloud-based software system will do this automatically on a regular basis. Brightpearl backs up all data nightly, stores it for 30 days, and can even perform a point-in-time restore, down to the nearest minute.

7. Perform regular audits

Even if you use inventory control software, you should still perform regular checks for theft, spoilage and possible human errors. You also want to ensure that each department is in communication regarding your inventory. Make sure your systems are accurately communicating with your accounting department the cost and count of your inventory.

Start improving your inventory control with Brightpearl

Effective inventory control is vital for any business, from a newly established brand all the way up to Amazon. It allows you to optimize your cash flow and reduce resources spent in inventory control. By using automated inventory control software systems and inventory control techniques, you can implement a strategy for inventory control that tracks your assets in real-time. Giving you visibility and control over your stock.

Even if your business has a relatively small operation, you can choose between a periodic or perpetual inventory system. However, if you have a large volume of stock or more complex processes, a perpetual inventory system is definitely a more suitable option. And if you look to complete your retail tech stack, research the best inventory system that can be seamlessly integrated with the rest of your business operations.

Discover how Brightpearl can transform your inventory control today. Book a free demo