Inventory is one of the most important assets for any business, and effective inventory management is especially critical in the fast-paced world of e-commerce. You have to meet the demand for fast delivery by ensuring there’s always enough stock to fulfill customer orders, but without tying up cash in excess inventory.

In this post, we’ll look at the importance of inventory management, share some tips and examples, and explain why retail inventory management software or better still a retail operating system like Brightpearl is essential for the task.

What is inventory management?

Inventory can include raw materials, components, and finished goods ready for sale. Inventory management is the process of handling and monitoring this stock in the most efficient way possible so that you always have the right amount in the right place at the right time.

It’s about knowing how much is needed and when to order it, and keeping track of everything across multiple locations and sales channels. If you get it right, you can reduce overheads and avoid problems like stockouts or overstocking. When ordering new inventory for your warehouse, you should aim to order the economic order quantity (EOQ).

With Brightpearl inventory management, you can track inventory throughout its journey and make accurate forecasts to ensure you meet future customer demand.

Inventory Management Defined

Technically, the definition of inventory management covers the period between stock arriving from a supplier and being shipped to a customer—that is, the time when it’s in your warehouse or store. But effective management involves tracking goods from the moment you place an order and monitoring the delivery and returns process.

Let’s clear up the meaning of inventory management and inventory control. The terms are often used interchangeably, but inventory management has a much broader scope. Inventory control, order management, supply chain management, and warehouse management can all be covered by inventory management.

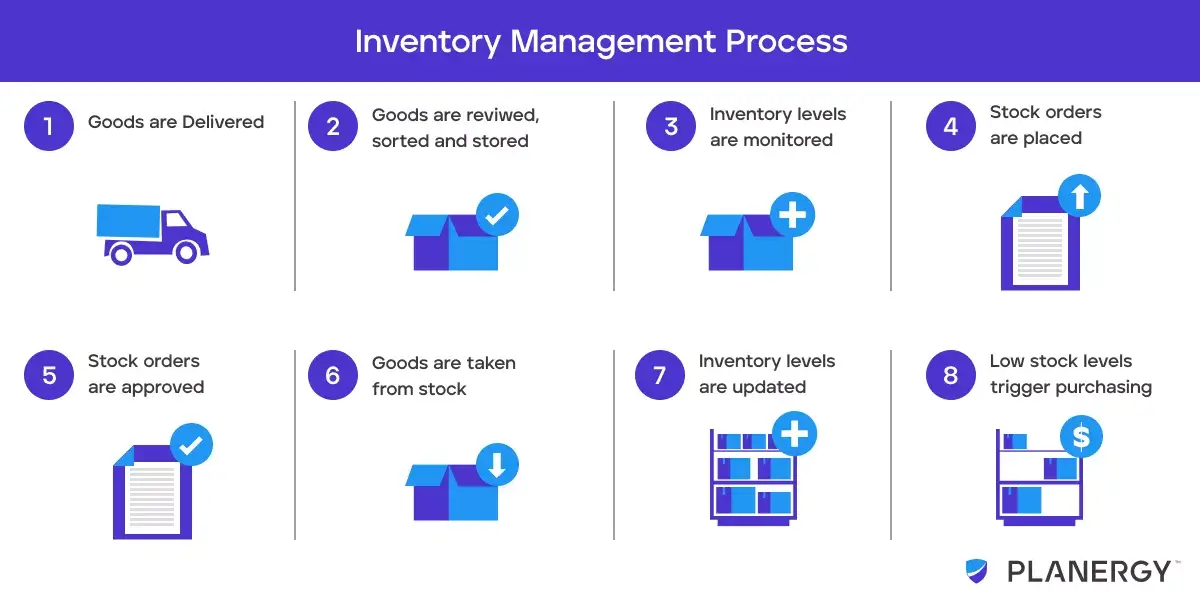

Source: planergy.com

How the Inventory Management Process Works

The process begins when you place an order with a supplier, although you might say it starts even earlier when you use forecasting to predict the required order quantity. As long as there are no delays, the goods will arrive at your warehouse on the appointed date.

Larger facilities will have a specific receiving area where inventory items are inspected and sorted before being put away. Each item is assigned an SKU (stock-keeping unit) code, which is entered into your inventory management system. Goods may also be tagged with barcodes or RFID (radio frequency identification) for easier tracking.

When a customer order is received online, the required item is picked from the shelf, packaged, and loaded onto a delivery vehicle or container ready for collection and shipping. Whether you’re selling online or through a physical store, your system should automatically update inventory levels whenever an item is purchased (and if it’s returned).

All of these stages can be carried out more efficiently with a properly managed process flow so that everyone knows what’s supposed to happen and when. By using automated inventory management to complete these tasks, you’ll save a ton of time and money—and avoid errors such as mispicks or duplicate deliveries.

Top Inventory Management Techniques

The methods you use will vary according to different types of inventory, with some being more suited to certain businesses than others. Let’s check out some of the main techniques of inventory management:

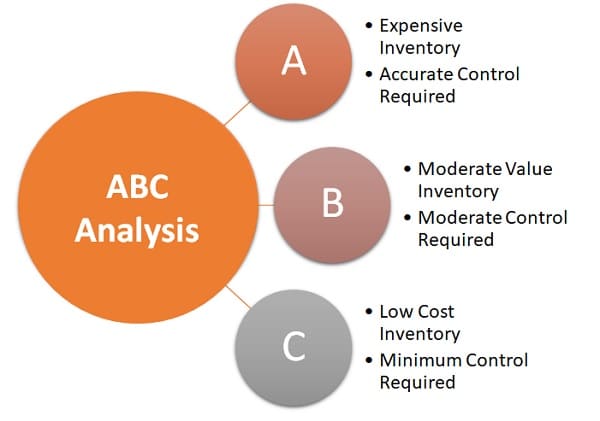

ABC inventory analysis

ABC analysis works by dividing stock into three categories based on their value and quantity. The idea is to identify the items that matter most to your business. (Ideally, you need an automated system to help you do this. Otherwise, it’ll be time-consuming.)

Source: deskera.com

Goods in category A are high in value but low in quantity, while category C items are low in value but high in quantity. Category B items are in between the two. Category A goods are more expensive but sell slowly, so you don’t need so many on hand. Category C products—although they don’t bring in much revenue individually—are essential to overall profits.

JIT (Just-in-Time) inventory

This method sees you strike a balance between maintaining the lowest possible stock levels and still having enough to meet demand. Goods are scheduled to arrive from suppliers only when they’re needed; “just in time” to fill customer orders. You don’t keep any safety stock on hand.

JIT can be ideal for smaller businesses that want to invest as little as possible in inventory and reduce overhead expenses. But it’s not without risk, so you’ll need a really robust inventory management system with advanced analytics and forecasting capabilities.

Dropshipping

The dropshipping technique means that goods are shipped directly from supplier to customer instead of being stored at your location in between. You don’t need to handle your inventory at all—you just sell the items via your website and pass customer orders straight to the dropshipper.

Smaller companies often favor this method because it eliminates the cost of warehousing. However, it’s harder to retain control over the fulfillment process, and you have to place your trust in the dropshipper. If there’s a problem, customers will still complain to you!

Consignment

Consignment inventory is when a consignor (usually a wholesaler) supplies goods to a consignee (usually a retailer) without the consignee paying for the items upfront. The consignor retains ownership of the inventory until it’s sold—at which point, the consignee pays.

The advantage for the consignee is that you don’t have the initial outlay for these goods, which is helpful if it’s a new product line and you’re not 100% sure if it’ll sell. Unsold products can also be returned to the consignor.

Cycle counting

Source: goodfirms.co

This inventory management technique involves regular counting of selected stock, rather than doing a full stocktake. These miniature physical inventory counts help you to ensure that the amount of inventory represented in your management system tallies with what’s actually on the shelves.

Cycle counting is most often carried out for high-value items or fast-selling SKUs. The benefit is that you can count this inventory without impacting your daily operations. However, it doesn’t tell you your overall inventory levels, so it’s not a substitute for a full count.

What are inventory management solutions?

Effective inventory management involves coordinating a lot of moving parts. Inventory management solutions include anything that makes this mammoth task easier, such as tools that help you streamline workflows for maximum efficiency.

The first step is to put together an inventory management plan detailing all the processes involved. Make sure everyone knows the policies for each task, and ask for feedback on what would make things simpler.

This type of inventory management planning will give you a head start as your business expands and your inventory turnover increases.

Even if you’re a small business, trying to handle your stock with entirely manual methods takes a lot of time and leaves you open to costly errors. It makes sense to use inventory management technology and automation such as barcode scanning and to use data analytics for forecasting.

Smart demand planning and inventory management will help keep inventory costs low while meeting customer expectations. Inventory management controls enable multichannel and multi-location fulfillment. In the next section, we’ll look at some of the software solutions you can use to achieve this.

How does inventory management software work?

Inventory management software streamlines your processes with automation and helps you keep track of stock at every stage.

You’ll have digitized, centralized records instead of spreadsheets and the ability to sync real-time data across locations and channels. The benefit is that you get more visibility into your operations, and you can make smarter decisions on how to optimize your inventory.

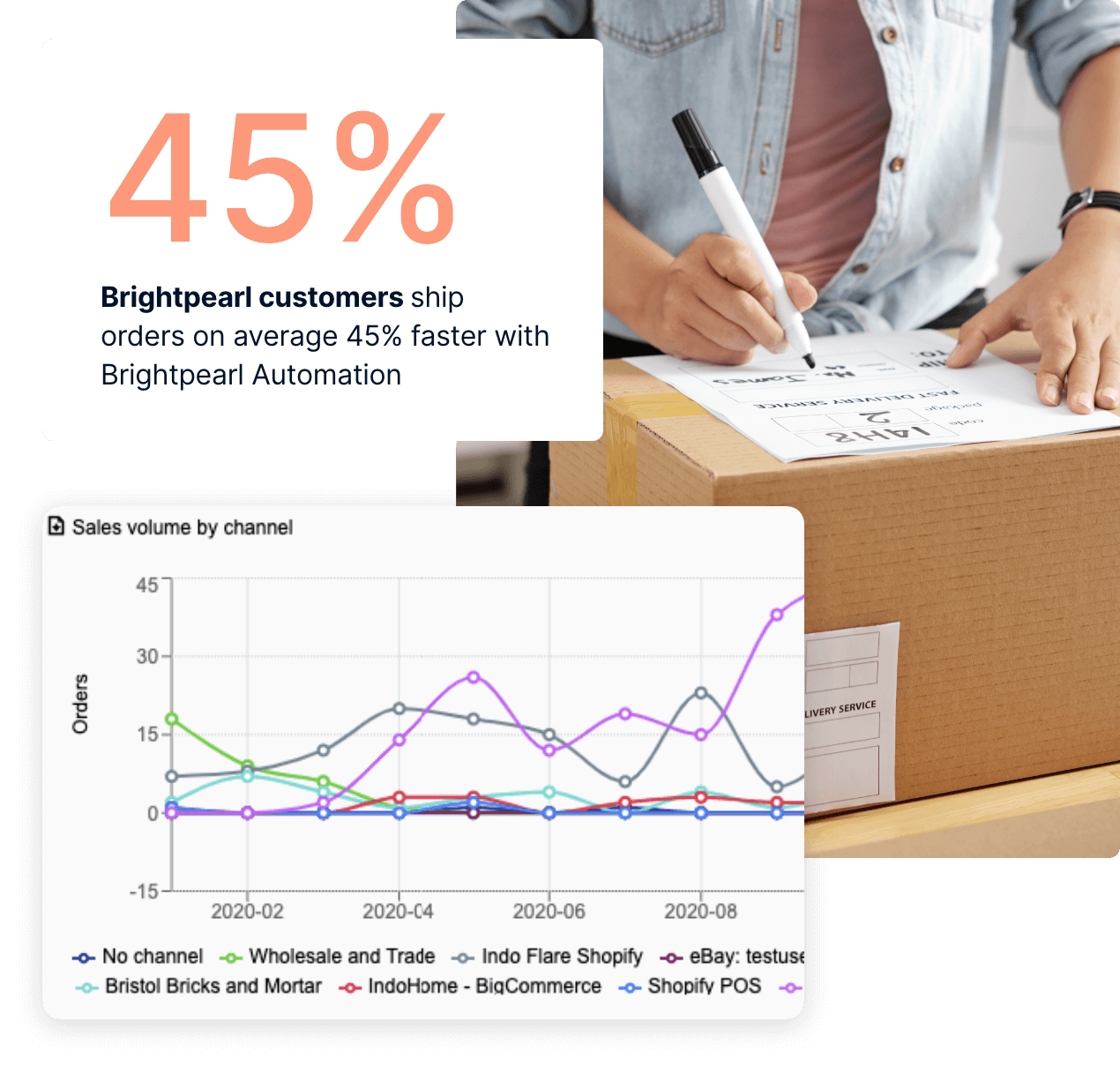

Why Brightpearl Is Built for Smart Inventory Management

Brightpearl is a comprehensive Retail Operating System that’s designed specifically for omnichannel merchants. It includes inventory and sales order management, order fulfillment and shipping, warehouse management, accounting, business intelligence, and built-in POS (point of sale) and CRM. It’s also endorsed by Shopify and BigCommerce.

Accurate inventory

Accuracy is everything when it comes to inventory tracking. Brightpearl automatically updates your inventory across all sales channels immediately after any new orders, replenishments, returns, and warehouse transfers. The integrated POS also syncs your online and offline channels in real time.

You can make full or partial cycle counts based on things like product performance, item value, and location and even track raw material inventory. Barcode scanning helps you to avoid shipping mistakes that can be costly and time-consuming to rectify.

Data-driven demand planning

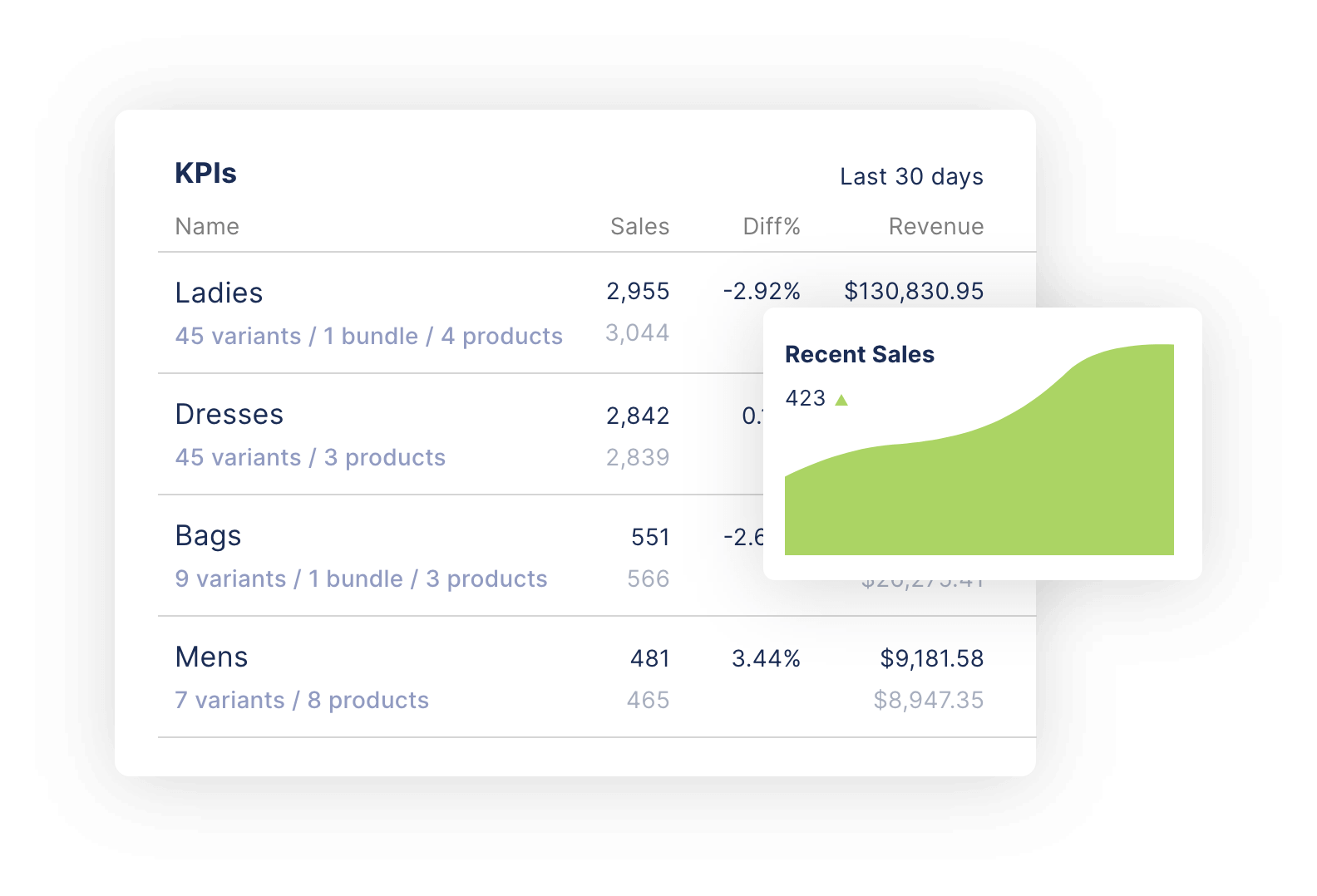

Brightpearl’s integrated Inventory Planner provides data-driven demand forecasting alongside robust analytics and reporting capabilities.

You can monitor changing customer demand, market changes, and new trends, as well as the sales performance of each item—taking seasonality into account. The system also gives you replenishment recommendations when an item is running low.

Time-saving automation

Brightpearl has a powerful Automation Engine that speeds up your critical operational workflows, potentially saving you two months a year on average. It also lowers labor costs by 50%, cuts shipping time by 92%, and reduces human error by 65%.

You can automate multi-location fulfillment (such as order routing, splitting, backorders, and dropshipping), allocate orders to different warehouses, and transfer inventory between warehouses. Automation also extends to printing shipping labels.

Product performance analysis

By combining data from all your sales channels, Brightpearl shows you which products are selling well and which could be doing better.

You can base this judgment on metrics such as the number of units sold over a given time, order volume, revenue, or even customer lifetime value. This analysis also helps with forecasting and warehouse optimization.

Instant financial insight

Brightpearl is backed by Sage, and advanced accounting capabilities are built right into the platform.

From the central hub, you can gain real-time insight into sales performance, profitability, and costs. Choose the FIFO (First-in, First-out) accounting model or account for your COGS (Cost of Goods Sold) at the point of shipment or invoice, and easily calculate landed costs.

Seamless reordering process

Enhanced visibility means you can easily see when something’s running low, but Brightpearl makes life even simpler by automating the reordering process. You can set your own reorder point, and the system will alert you when it’s reached.

The handy Replenishment Report shows you which products need to be reordered and in what quantities. It’ll even suggest which supplier to use, and you can create purchase orders in one click.

How to choose an inventory management program

When it comes to choosing inventory management services, it’s helpful for business owners to make a list of required tools and features. Encourage input from the employees who will be using the new system, fix a budget, and research the solutions available.

It’s always worth getting a free trial of the software. As well as ease of use and scalability, you’ll want to look at security, uptime, and level of support. Be aware of any hidden fees, and check if integrations are pre-built by the vendor.

Some businesses choose to use standalone inventory software and connect it to a WMS or OMS platform. You could also implement a modular ERP (Enterprise Resource Planning) solution, but in both cases, you’ll likely end up paying more than you would for an all-in-one platform like Brightpearl—and you still won’t have full functionality.

Best examples of effective inventory management

Here are a few examples of companies that have nailed their inventory management strategies:

Toyota

Toyota pioneered the JIT method in 1970, and it proved so effective that they’re still using it today.

In their strategy, raw materials for auto manufacturing are not brought to the production floor until a customer order is received. Toyota can minimize the amount of inventory it holds, which not only reduces costs but also enables them to adapt to changing demands.

Apple

Apple also uses JIT principles within its manufacturing process but in a slightly different way.

Apple’s strategy is built on strong supplier relationships, which allows production to be outsourced in order to keep costs down and reduce the risk of overstocking. Apple has 150 key suppliers worldwide but just one warehouse in the US—and most of its inventory is housed in its own retail stores.

IKEA

The global retail business has remained highly competitive in a very saturated market thanks to efficient inventory management.

IKEA has a replenishment process with maximum and minimum settings for reorder points. For each product, they know exactly how low the stocks can fall before reordering becomes necessary and the maximum amount they need to order at one time.

Other well-known examples of smart inventory management include that implemented by Amazon. The online retail giant uses machine learning algorithms to provide customized restocking strategies.

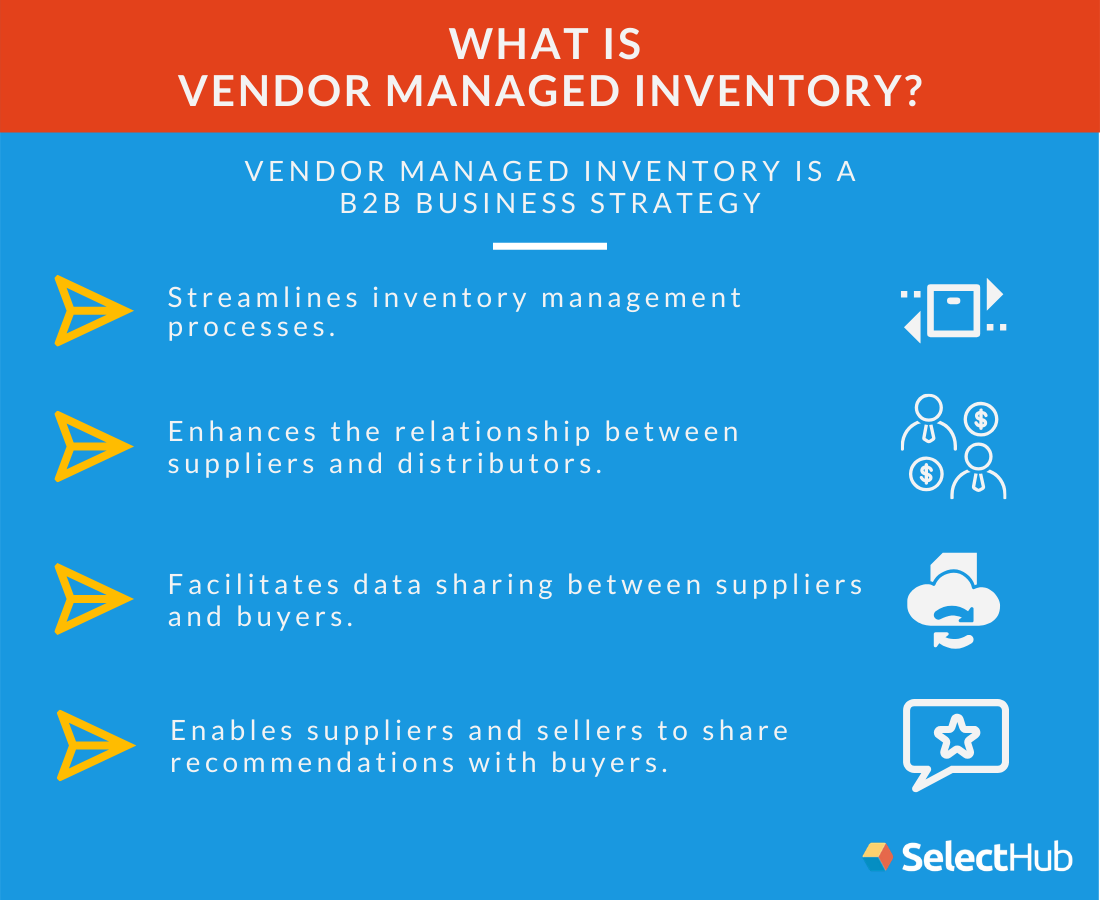

Walmart’s vendor-managed model, meanwhile, means suppliers can access their own data from Walmart’s information system and have more control over their inventory management requirements.

Source: selecthub.com

Inventory Management Tips for Small Businesses

1. Understand your inventory

Effective inventory control starts with understanding what you have in stock, how it’s performing, and when you’ll need more of it. You need to keep accurate records for each item and ensure your system updates every time there’s a change to the inventory.

If you don’t do this, how will you know if any products are missing or if they’re stored in the wrong place? This is especially important for perishable items that must be stored correctly.

2. Know your priorities

Each business has different priorities, so you should determine what you want to achieve with an inventory management system. Are you most concerned about reducing storage costs? JIT or dropshipping methods can help.

Are your goods frequently out of stock, leading to disappointed customers? Consider keeping safety stock or changing suppliers. Of course, a robust inventory management solution can handle all these issues and more.

3. Consider manual stock counting

There’s a strong case for automation in inventory management, but sometimes there’s room for the human touch.

Manual stock counting acts as a backup for your digital systems, and it’s useful for counting low quantities of high-value items. You’re more likely to discover obsolete, stolen, or damaged stock if you check it in person.

4. Build the best practices

First of all, think about any inventory-related problems your business faces, such as lack of visibility, mispicks, or spoilage. Then consider the ways you can address them. Often, this will be through using technology.

For example, introducing barcode scanners will help warehouse staff locate the right items and optimizing warehouse layouts will save them time. You could also upgrade your packaging to avoid damaged shipments.

5. Connect with your suppliers

It’s vital to maintain a strong relationship with your suppliers, and it’s not just about being aware of lead times. With regular communication, you’re better placed to negotiate good deals, and you’ll get an early heads-up if there’s a supply chain delay, giving you time to source products elsewhere.

You should monitor your suppliers’ performance and ensure you’re getting the best value. Brightpearl gives you a dedicated portal for supplier management.

Online Inventory Management & the Power of Cloud

Manual inventory management methods used to be widespread, and some small businesses still use them. But the problem is that manual work is time-consuming and error-prone.

Paper records can easily be lost or destroyed. If you’re counting inventory and writing figures by hand, you can easily get distracted and add an extra zero. And the larger your inventory gets, the harder it is to track manually.

By taking inventory management online, you can digitize your records, automate processes, and keep everything in one place.

The system should update automatically whenever there’s a change. Alongside increased visibility, many online systems include analytics, reporting, and forecasting capabilities to inform your inventory planning and help identify growth opportunities.

Cloud-Based Inventory Management: Why It Matters

Even if you’ve digitized some processes, you might still have an on-premises system with the software installed on your own computers. As you’re responsible for maintenance and upgrades, you’ll need an in-house IT team—not to mention space to keep bulky servers.

The alternative is a cloud-based solution, where all your systems and data are housed and maintained by your provider, and your whole team can access the system from anywhere. Cloud-based inventory management makes it easy to scale, as you pay a flat monthly subscription and add more users or features when you need them.

Choosing the Right Inventory Management Program

Brightpearl isn’t the only solution for inventory management on the market (although, in our opinion, it’s the best). Here are a few alternative solutions and how they stack up:

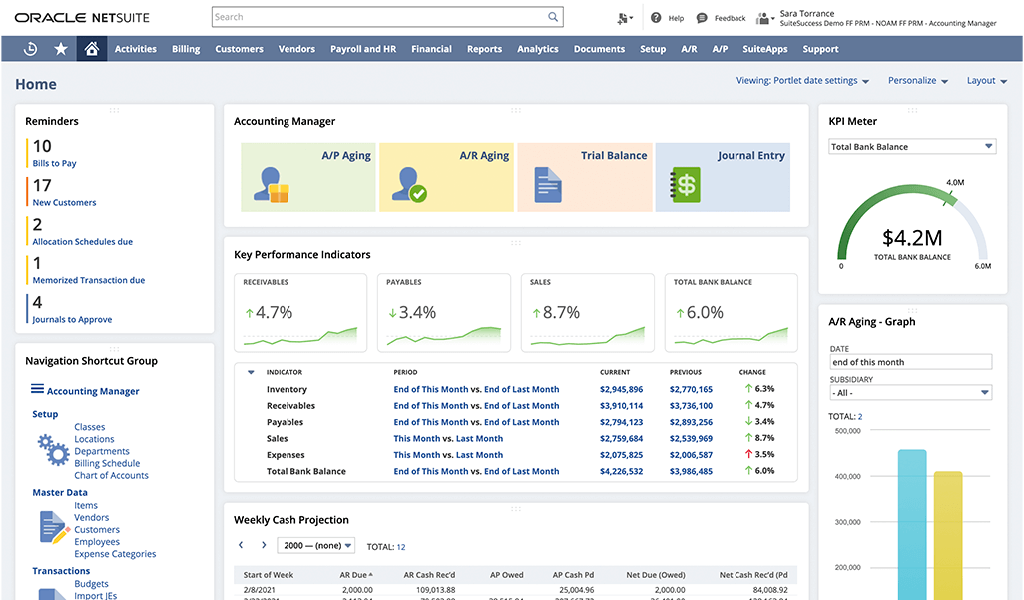

NetSuite

Source: Capterra.com

NetSuite is a modular ERP system that includes inventory control. It provides a real-time view of inventory and minimizes manual processes with automatic tracking.

It enables multi-location fulfillment, demand-based replenishment, cycle counting, and lot and serial tracing. The versatile features mean there’s a steep learning curve, though.

NetSuite is very much a one-size-fits-all solution rather than being retail-specific. It doesn’t have many integrations, doesn’t use APIs, and charges extra for Shopify Connector. If you’re an omnichannel retailer, you’ll likely require customizations to meet your requirements. Plus, you’ll be paying for features and elements you don’t need.

Your annual license fee covers the core platform, optional modules, and the number of users. You can add new modules and users when required for an extra charge. There’s also a one-time implementation fee.

The average implementation time is 420 days, compared to Brightpearl’s 120 days. Even then, traditional ERPs like NetSuite experience failed implementation 50-75% of the time, while Brightpearl has a 97% success rate.

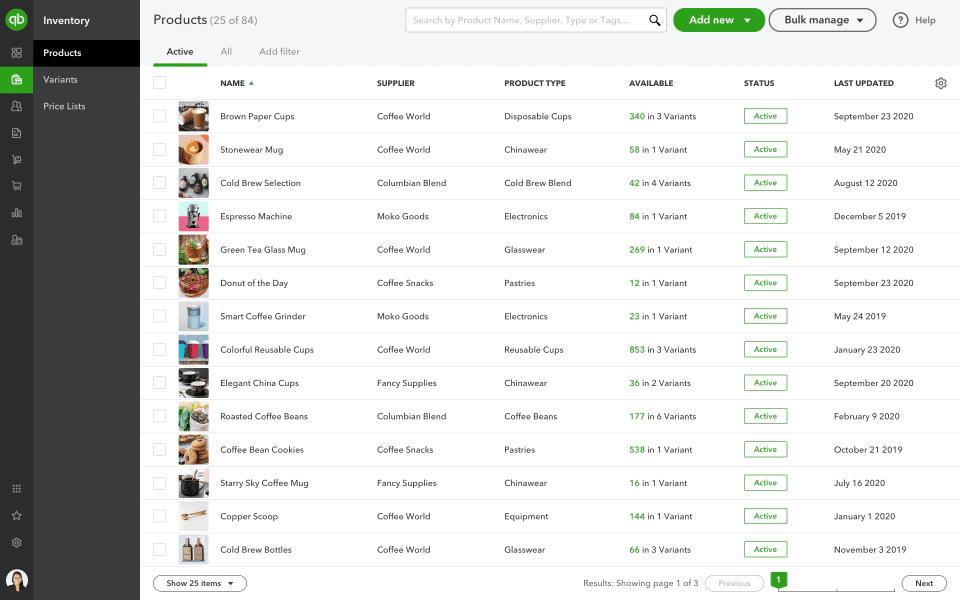

QuickBooks Commerce

Source: capterra.com

QuickBooks Commerce is a B2B-focused cloud-based system that comprises inventory management, order processing, and supply chain management. Inventory levels update automatically, and the solution includes reporting, reorder alerts, and barcode scanning.

It’s designed to work seamlessly with QuickBooks Online’s accounting suite, but Commerce is only available as part of that bundle. It’s still affordable, currently $52.50/month for the first three months (regular price: QuickBooks Commerce $50/month and QuickBooks Online Essentials $55/month). If you already have QB Online, you can add Commerce for $25/month for the first three months.

However, compared to Brightpearl, QuickBooks Commerce may not be able to handle complex operations like flexible fulfillment, dropshipping, or backorder management. It doesn’t have flexible payment options or high-volume connectors (the integration with Xero is unreliable).

Neither does it support any POS integrations, which isn’t ideal if you have physical stores. Generally, the features are less advanced than Brightpearl, especially when it comes to customizable workflow automation. The website describes QB Commerce as “currently available to a limited group of customers” and mentions a wait-list.

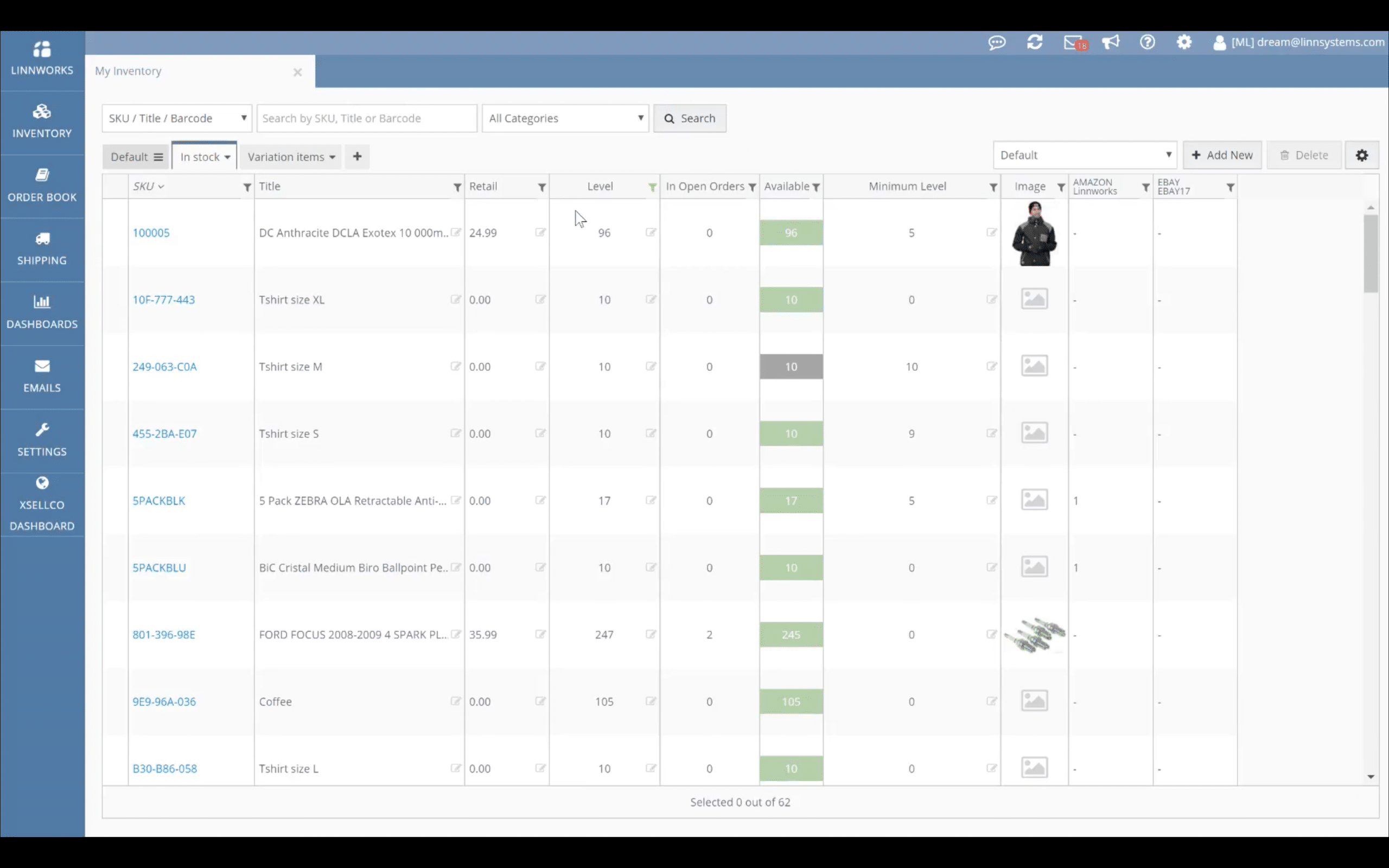

Linnworks

Source: capterra.com

Linnworks is a cloud-based platform for e-commerce retailers, enabling you to manage sales and inventory across selling platforms. It has order management automation (including purchase orders) and demand forecasting with real-time data and the ability to manage supplier relationships.

There are 70+ marketplaces and multichannel integrations, and you can connect major carriers and fulfillment services. But it doesn’t have integrated real-time accounting or native integrations to third-party accounting software.

Linnworks has only limited automation rules, and you’ll need some coding knowledge to set them up. In comparison, Brightpearl allows you to automate more workflows. Linnworks doesn’t offer integrated payments or flexible payment and invoicing options, and it doesn’t have built-in POS, CRM, or WMS.

No pricing is shown on the Linnworks website, but some reviews mention changes to the pricing structure and limits on order numbers. Those reviews also cite a difficult setup, glitches, and clunky workflows.

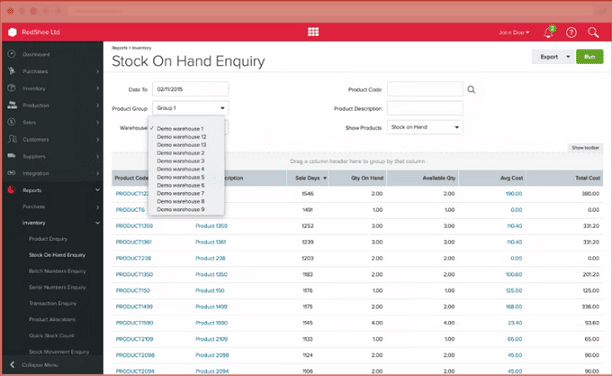

Unleashed

Source: capterra.com

Unleashed is a cloud-based solution that lets you track stock in real-time across multiple locations. You can set minimum and maximum stock levels and receive sales alerts telling you which orders need to be fulfilled. You can set up batch and serial number tracking, and there’s a mobile app for Android and iOS.

There are no native integrations to BigCommerce, Magento, and eBay—you’d have to build a custom connector. There’s no advanced reporting, integrated inventory planning, flexible fulfillment workflows, or POS or WMS capability. Another downside is that you can only use the average landed costs methodology, not FIFO/LIFO.

Quite a few features are paywalled, such as modules for B2B e-commerce, business intelligence, and shipping. You also pay extra for a customer success plan (that’s included with Brightpearl) and mandatory remote onboarding packages. The three pricing plans all have fairly limited user numbers—the most expensive only accommodates 20—but you can pay to add more.

Reinforce your inventory management strategy with Brightpearl

If you’re looking for all the functions of an advanced inventory management system, Brightpearl gives you everything you need.

Thanks to the great integration partner ecosystem and APIs, you can create a tech stack that scales as you grow. As well as complete visibility and accurate forecasts, Brightpearl automates complex order processing and fulfillment workflows to save you time and money.

Brightpearl is made for retail and wholesale businesses, and you’ll be guided by retail operations experts at every step. They’ll ensure that you and your staff are fully trained before your account goes live, and you also get a Customer Success Manager plus unlimited phone and email support as standard.

FAQs about inventory management

Why is inventory management important?

– The objective of inventory management is to ensure there’s enough stock to meet demand while keeping overheads and labor costs low. If you get it right, you’ll avoid problems like shortages and dead stock, as well as improve your cash flow.

Effective inventory management gives you improved forecasting capabilities and supplier relationships, and helps you optimize warehouses to reduce spoilage.

How can you improve inventory management?

– Inventory software is vital for good inventory management, so use the tools of inventory management to your advantage!

Instead of spreadsheets, invest in a cloud-based system (like Brightpearl) that keeps all your data in a central hub, syncs your channels, and updates inventory levels automatically.

This real-time visibility will help you make smarter decisions, especially if you can also manage orders, warehousing, and suppliers on the same platform.

How does inventory management work?

– Inventory management involves keeping track of your stock as it moves through your business. It’s vital that you can trace any item at any given time, so many businesses use barcode or RFID scanning to enter SKUs into the system. It should then update whenever goods are sold, shipped, or returned.

Inventory management also involves planning ahead, so you’ll need forecasting tools and low-stock alerts. That way, you’ll always have the right amount of stock in the right place at the right time—which will keep customers satisfied and improve your bottom line.

How does inventory management work in e-commerce?

– It uses software to sync inventory across warehouses and sales channels, automate stock updates, and forecast demand to ensure timely fulfilment.

What are the best tips for managing inventory?

– Use automation, maintain accurate records, do regular cycle counts, forecast demand, and build strong supplier relationships.

Why is inventory management important?

– It ensures you always have enough stock to meet customer demand without overspending on storage or stock that doesn’t sell.