In a company’s inventory, nothing can hurt the bottom line more than over or under stocking a product. Employing modern inventory management can help businesses maximize their profits and mitigate risks. But it’s not enough to track what’s in your warehouses and stores, you need to factor in your pipeline inventory, too.

Maintaining an up-to-date view of your entire stock is crucial for efficient and effective inventory management. More accurate inventory counting will aid budget analysis, carrying costs, and sales forecasting. By tracking pipeline and decoupled inventories, businesses can guard against inventory loss and gain a competitive advantage.

What is pipeline inventory?

Pipeline inventory refers to the products that a business has en route. Typically, when a retailer orders a product from a supplier, there is a lead time until the order will be received. But no matter how long the lead time is, the product counts as part of the buyer’s inventory as soon as it has been paid for.

Other than raw materials, most products will require some type of manufacturing time. And almost all types of production will require some type of transportation. Because of this, it’s highly unlikely for a retail business to not have any pipeline stock.

The ultimate destination of pipeline inventory could be an e-commerce warehouse or a brick-and-mortar store. When it arrives at that destination, it immediately becomes part of the standard inventory count.

Pipeline inventory is not to be confused with in-transit inventory which is a type, but not the entirety, of pipeline inventory. In-transit inventory specifically refers to the stock that has been collected for transport to the purchaser. Pipeline inventory encompasses stock at all points post-purchase. This is regardless of whether the product is physically on its way via freighter, or still on the factory manufacturing floor.

Calculating your pipeline inventory helps you see how much cash is tied up in inventory, along with other overheads, such as transportation and carrying costs. It’s especially important for businesses with long lead times.

This past Christmas, there was a disconnect between the supply and demand of a certain next-generation gaming console. Many stores sold pipeline inventory. This was because console lead time was several weeks to months long. Gaming retailers sold their entire inventory, despite not physically having the consoles at the time of sale.

Businesses that had accounted for their pipeline inventory were able to pre-sell the items and meet the extremely high demand. With known lead times, customers were aware of the delays in their receipt of goods. Without awareness of what stock was in their pipeline inventory, businesses would not have been able to meet demand, and would have lost valuable sales.

As another example, let’s take a clothing wholesaler. The company orders some jeans and some dresses from China. After payment, the jeans are loaded onto a freighter and are on their way the next day. They are now part of the wholesaler’s pipeline inventory, even though they may not arrive at the company’s warehouse for another two weeks.

How to calculate pipeline inventory

Does your e-commerce business want to stay on top of pipeline inventory? Then you first need to know how to calculate it. Let’s consider a scenario where a retailer orders a ready to sell item from the manufacturer. The products have been paid for by the retailer. But now there will be a lead time between payment and the receiving of the products.

Once we know how long the lead time is, we have half of the equation. Next, we need to know what the demand rate for the item is. That is, how many units are sold with regards to time. This could be per week, per month, or per quarter. But to keep it simple, a demand rate per ordering period is optimal.

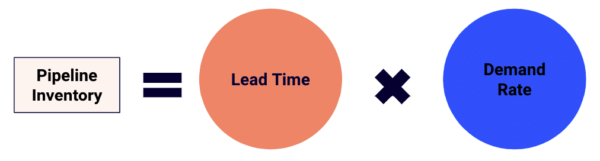

So now we can look at pipeline inventory with the relevant terms:

Let’s look at the gaming console example again. Our lead time is the amount of time it takes the retailer to get the console. Shipment from the manufacturer is four weeks. And our website is selling one hundred consoles per week. That would be the demand rate. So, calculating the pipeline inventory we get the following:

4 weeks * 100 units per week = 400 units

That means we would need to order four hundred console units per order to maintain consistent inventory levels.

An alternative to calculating the pipeline inventory would be to calculate the economic order quantity (EOQ). This number tells a retailer how many units should be placed in an order. But also with an aim to reduce inventory carrying costs. The limitation of using EOQ is that you must first have an annual demand rate, fixed costs (including your annual pipeline inventory cost), and an annual carrying cost per unit.

What is safety stock, and why does it matter?

So, you’ve figured out your average pipeline inventory. Accounting for pipeline stock makes inventory management efficient and more precise. But it doesn’t mitigate risks from production stoppages and transit slowdowns. In this case, retailers will eventually see their inventory run down to zero.

During this waiting period businesses will miss out on potential sales. As an insurance policy against the loss of sales, retailers can keep a reserve stock.

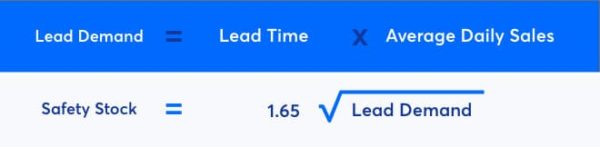

This will increase a company’s holding costs. Therefore, costs must be weighed against benefits. For each business, the reserve stock numbers will depend on many factors. However, a basic formula for calculating safety stock is:

(Max Daily Usage x Max Lead Time) – (Average Daily Usage x Average Lead Time)

This will give you the amount you need to have in stock as a reserve.

A simpler method for calculating safety stock is to take the average number of item sales per day and multiply it by the number of days you would like to keep in reserve. This way even small e-commerce retailers can find a holding stock level that works for them.

What is decoupling inventory?

Decoupling inventory refers to a separation of stock into components. The purpose is to overcome unforeseen stoppage in production or other mishaps. In this way, decoupling inventory can be seen as a type of safety stock. In other words, decoupling inventory is a safety net for businesses to rely on when unexpected slowdowns or fluctuations occur.

The inventory is decoupled into different points and components that usually come from different suppliers. And these components will each have their own variables and lead times.

The goal of decoupling inventory is not to be able to deal with peak season or spikes in demand. That is a part of inventory management that would be better served by sales forecasting for optimal stock levels. Decoupling inventory is an insurance policy against any issues that may affect the pipeline inventory.

Examples of decoupling inventory

Decoupling inventory is typically used by manufacturers. Let’s say a guitar producer needs guitar necks, guitar bodies, and electronics from three different suppliers. One of each item will allow for the assembly of one guitar.

We could only count the completed guitars in stock. But manufacturers can gain much more insight from the decoupling inventory. That is, how many guitar necks, guitar bodies, and guitar electronics are in stock. This will ensure a lack of over or under stocking assembly components.

The decoupled inventory can also work like pipeline inventory with regards to lead times. Components can be ordered to fit different lead times and production durations. But with the decoupled inventory system, the producer can also maintain an inventory of the necessary parts at levels that make sense.

Some items in the decoupled inventory will be produced at different rates and be received in varying waves. This can be even more pronounced when dealing with overseas shipments.

Essentially, assembly parts are ordered at levels that eliminate bottlenecks in production. This allows for predictable holding costs and reliable inventory levels of consumer-ready products.

Without bottlenecks, retailers should expect consistent lead times and maintain optimal stock levels. This allows a business to maximize its cash flow. But also helps to maintain production. This is by better preparation for unforeseen delays in the supply chain.

5 expert tips for managing pipeline and decoupled inventory

Accurate tracking of pipeline inventory will help businesses keep a healthy bottom line and provide a true picture of your company’s cash flow. And well-planned decoupling can hedge against inevitable obstacles in production lead times. Here are a few tips for managing the pipeline and decoupling:

1. Track your inventory at every stage

The first step to managing pipeline and decoupled stock is to track where they are in the supply chain. There is no use in segmenting inventory if you have to guess the actual levels of transit stock. You should know where they are in the manufacturing process and at all points in-transit to the retailer.

Most manufacturers and suppliers will supply real-time logistics updates. And the same applies to any freight or supply courier services. Make use of real-time scanning technology via barcodes, stock keeping units (SKUs), and smart devices. These technologies should be easy for most businesses to implement.

2. Monitor external disruptions in your supply chain

Retailers must never ignore what is happening in the world around them. Disasters, political crises, pandemics, and more can have immediate short and long-term effects on businesses.

Keeping an accurately tracked and accounted inventory will give your business more time to deal with unforeseen customs delays with overseas imports. Safety stock can be a lifesaver for a small retailer during a manufacturing strike. Retailers should have contingency plans in place to respond to a variety of unexpected disruptions.

3. Consider Safety Stock

In most cases, pipeline stock is completely out of the retailer’s control. No matter how accurate a pipeline inventory count is, businesses can always plan on the unplanned occurring. This can be even more likely when dealing with imported products.

Decoupling stock helps coordinate lead times to get consumer-ready products with consistent cycles. But it isn’t the only contingency plan a business should have in place. And for most retailers, a lot of stock simply can’t be decoupled.

A good insurance policy is to maintain certain levels of safety stock. This backup inventory mitigates production slowdowns due to transit delays, or manufacturer issues. If shipments are delayed, safety stock can ensure customers get their items when expected, meaning more happy – and more loyal – customers!

4. Use automation to streamline inventory management

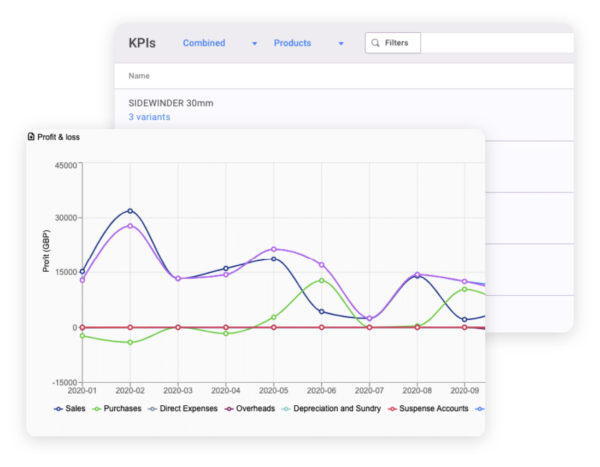

It’s well worth making use of third-party automation to help manage inventory. Calculating your pipeline inventory is just the beginning. An inventory management platform can provide stock reports and make reordering more efficient. And most software will allow for auto-replenishment to maintain a set amount of inventory.

Many platforms integrate with e-commerce tools, and allow for predictive lead times and sales forecasting. This means pipeline stock can be adjusted on-the-fly and automatically to ensure you are able to fulfill all of your customer’s future orders. E-Commerce retailers can optimize order storage and fulfillment with Brightpearl, leading to more efficient processes and higher customer satisfaction.

5. Use a real-time Inventory Management System

As well as automating what they can, retailers should look to modernize with inventory management software. Inventory is in a state of constant change due to sales, returns, orders, and receipts. Staying on top of an accurate inventory count can be difficult. By using a real-time inventory system, retailers have access to accurate stock data as needed.

Real-time inventory management will help you prepare for the unexpected, and you can make use of available data to gain valuable insights. Solutions like this let you detect inventory problems as early as possible, leading to quick solutions.

Additionally, it’s easier to track a decoupled inventory with a management platform. You can use the solution to optimize individual supplier order cycles by making use of valuable metrics and data. The precision of decoupling stock eliminates the growing pain of newly implemented stock control.

Aligning your inventory strategy with modern retail realities

Effective inventory management today is no longer just about knowing what’s on your shelves. It’s about staying one step ahead—anticipating stock needs, balancing cash flow, and responding quickly to market shifts. That’s where pipeline inventory and decoupling inventory strategies come into play.

Learning how to calculate pipeline inventory and implementing safety stock or decoupling techniques can help your retail operation avoid costly delays, missed sales, and customer dissatisfaction. These approaches help you maintain continuity even when your supply chain hits a snag.

Whether you’re facing long lead times or managing global suppliers, having visibility into your pipeline stock ensures unexpected disruptions do not blindside you. Decoupling adds another layer of flexibility, letting you respond dynamically to production slowdowns without halting your entire workflow.Modern inventory planning systems, like Brightpearl, can help you track and automate these strategies—offering real-time updates, demand forecasting, and reliable stock insights.