Inventory management can be a challenge, especially when you’ve got store inventory control to consider, with several warehouses and retail stores to maintain. It often involves a stock-take day, when you count each item of stock in your warehouse and record the results.

Although store management and inventory control can sometimes be tedious, it’s vitally important for a business to stay on-track with its inventory levels.

Holding onto too much stock can disrupt your cash flow, which is bad for business. But not having enough to meet customer demand is equally damaging.

That’s why effective inventory management is vital for a growing business. Luckily, nowadays, there is plenty of useful inventory management software available that can help with stock control, making the process smoother and easier than ever.

So, read on to learn more about the meaning of store inventory control and how it can impact your business.

What is Store Inventory Control?

Store inventory control is the process of keeping track of stock levels across your retail stores. This can relate to both physical and ecommerce online stores. It encompasses everything from purchasing right until the point it reaches the retail store.

That means monitoring incoming and outcoming stock, as well as the stock being held in the warehouse. Inventory control gives you a complete overview of your company’s inventory, including what the products are and where they can be found in the warehouse.

The goal is to minimize the costs that can be incurred through holding onto stock. You’ll also have a better idea of when to replenish stock, sell old stock, and buy new products. Good inventory control techniques will free up space in your warehouse as well as money in your cash flow, and ensure you’re not keeping hold of old or unsellable stock.

According to Shopify, mismanaging inventory has cost businesses nearly $2 trillion. These are mostly hidden costs associated with overstocks, out-of-stocks, and preventable returns.

Why Store Inventory Control is Important

Inventory control gives a business owner a better understanding of their stock levels. It ensures that dead stock is taken care of (or avoided entirely), and that the warehouse is running at optimum efficiency. Here are some other reasons as to why inventory control is important for your business:

- Helps with quality control – Inventory control allows you to keep an eye on your products, wherever they are. That means that every now and again when you conduct inventory counts, you’re also able to monitor quality control at the same time. If you do find stock that falls below your company standards, there is then the opportunity to act. Especially in the event of a product recall.

- Keeps count of stock – Part of the inventory control process is conducting regular stock takes. This involves counting every single item of stock you have. It allows you to monitor stock levels and organize your warehouse.

This is important because it means you know where each unit is located, and the quality and condition of each product. You’re also able to see where you may be falling short on some products and bring in additional stock where necessary. - Helps with inventory accounting – Inventory accounting is a key part of inventory control. It measures the value of physical inventory and costs of goods sold over time.

This means you control dead stock that no longer has value, which reduces waste and makes it easier to calculate your inventory value. This also means you can help your bottom line by only holding the products you need. - Ensures you don’t oversell – Once you know how many products you have, you can be sure that you don’t accidentally oversell an item to your customers or sell out of your most popular product. You can also list your stock levels in real-time on your website, and keep your POS (point of sale) system updated with in-store stock availability.

When items are sold out, customers can grow impatient and look elsewhere to find the same product. Similarly, when a customer buys an item only to find out it’s been oversold and they’ve been refunded, this can also leave them frustrated with your quality of service.

Overall, it can decrease customer satisfaction ratings for your store. Given that customer experience goes hand-in-hand with loyalty, it’s important that you deliver the best service possible.

The 4 Types of Inventory

There are four main types of inventory. Let’s take a look at what they are and how they impact businesses.

Raw materials

These are the materials used to manufacture product components or finished products. In some cases, these materials are kept by the supplier and then shipped directly to you. However, sometimes the materials may be produced by you for easy, quick access. This means they may be part of your warehouse inventory. For example, if your business sells notebooks, the raw materials you need to make them include the paper, ring binders, and covers.

Unfinished products

This type of inventory includes products that are eventually going to be for sale, but are unfinished or not yet ready to hit the shelves. This may include products that are still being made or are waiting for packaging to complete the item. These will be stored in a separate part of the warehouse to ensure everything is categorized and an unfinished product never makes it into a store.

In-transit inventory

This refers to the inventory that has been shipped from the supplier but has not yet reached the warehouse. It’s also referred to as pipeline inventory. This transaction is still included in inventory management, even though it’s not reached the retailer yet. It’s also where the transfer of ownership takes place. When goods arrive with the purchaser, they now own those goods.

Cycle inventory

Cycle inventory is when a business sells a portion of its stock. This stock is then swiftly replenished. Safety stock is used to cover surges and dips in demand, while cycle stock is used to cover the majority of purchases. This means that some small businesses only use cycle stock because they don’t have the capacity for safety stock.

For larger businesses that have safety stock, they may still avoid dipping into it unless it is needed to meet increasing customer demands. Keeping cycle stock as low as possible saves money on shipping and storage, which can be useful for smaller businesses.

Challenges of Store Inventory Control

Inventory management can be challenging for retail businesses for several reasons. The biggest challenges are:

Issues with supply chain

The supply chain goes from the manufacturing stage right through to the warehouse, and the products on the shelves. Below are some typical supply chain issues.

When there is an issue at any of these stages, it can affect the whole chain. One of the challenges of inventory management is to be prepared when a problem arises. You must act quickly to fix it.

For instance, you should re-order your best-selling product frequently so that you can keep large quantities in your warehouse. So, if there’s ever an issue with sourcing raw materials or delivery of the products, you’ll have enough stock in the warehouse to prevent stockouts until new stock arrives.

Managing warehouse space

Inventory control techniques aim to minimize the stock levels in your warehouse. Sometimes, this is out of your control – like when there are issues in the supply chain, for example. Your warehouse may only have enough space left for your incoming products, but a problem with the supply chain may mean some products are delayed.

Therefore, they could all arrive at the same time. It’s important to ensure you’ve got excess space for eventualities such as this.

Planning and designing efficient, effective warehouse spaces isn’t easy, but you can better control the timing of new stock deliveries when you organize your warehouse spacing.

Customer demand

It may also be the case that you bulk buy products because of demand, but then trends change and they fall out of fashion. You’re then left with thousands of products in your warehouse taking up space that could potentially house new, more successful ones.

On the other hand, you may buy small quantities of a certain product but then find out that it’s growing in popularity. If you haven’t got enough stock in your warehouse, then this may cause delays in getting products to the customer. Let your supplier know when you’re generating a lot of purchase orders so they can ramp up production. Ensure you’re using a fast and reliable supplier that can do this for you.

Forecasting trends can be difficult, so it’s important that you use demand forecasting. This is when you analyze data to predict how many products are going to sell within a certain time-frame. You can ensure you have enough for peak times like the holiday season.

Poor communication

Retail managers should be highly-skilled communicators. If communication between suppliers or manufacturers breaks down, it can cause issues for inventory levels. Good communication is particularly necessary if your business operates on a large scale and has both physical and online stores.

Managers need to be able to implement the company’s inventory management techniques, as well as train other employees in the warehouse. It’s important to document lead-times and supplier information. To ensure this is available across multiple warehouses, the information needs to be digitized. Sometimes a warehouse management software system can be the easiest solution.

Poor communication can affect your bottom line, too. Here’s why:

Increasing competition

Increasing competition can present a couple of problems. One being that you need to keep your product in stock at all times, because if repeated stockouts affect the loyalty of your customers, they won’t be afraid to shop elsewhere for the same thing.

Another issue is that the demand for raw materials or for your products from suppliers may increase in line with supply and demand. You can compete for high-demand materials, but this will come at a cost.

Changes to packaging

As consumer tastes change, so do products and their packaging. If ingredients change or there’s a limited edition product, you can expect the packaging to change with it. This can be tricky for inventory management, as you’ll have a lot of products that are suddenly out-of-date.

This may mean some of your products have a shorter shelf-life than you were expecting, and you may make a loss if you aren’t able to sell them on. Of course, the product inside may be exactly the same as it always has been—but the customer will want the shiny new packaging design!

8 Inventory Management Techniques and Examples

If you’re wondering how to control inventory in retail stores and warehouses, keep reading!

Depending on the business, there are various types of inventory control techniques. Here are eight examples of inventory management systems in business:

1. First in first out (FIFO)

As the name suggests, this technique means that your oldest stock gets sold first. It’s a good way to keep track of the re-order point for stock, and avoid the issue of dead stock. For food and beverage retailers like Starbucks, this is a particularly important technique needed in order to keep products fresh. Even if you’re not selling perishable products, it can still be a good idea to use the FIFO method. If for no other reason than to ensure packaging is always in good, up-to-date condition.

A FIFO system only really works well with an organized warehouse. One where you know the location of each product in order to keep replenishing stock. Warehouse management software like Brightpearl can be useful for this. It enhances warehouse visibility so you can stay on top of your inventory. It also eliminates costly warehouse human errors thanks to its barcode scanner and automation options.

2. Last in first out (LIFO)

This technique means that the inventory you’ve most recently received will be sold first. The reason for using this method is all about pricing. If prices rise, this means the inventory you most recently bought will be the highest cost. When you sell these items, you’ll generate lower profits and therefore, have a lower taxable income.

One of the downsides of this technique is that you’re more likely to generate dead stock. If it’s left for too long, it may be unsellable.

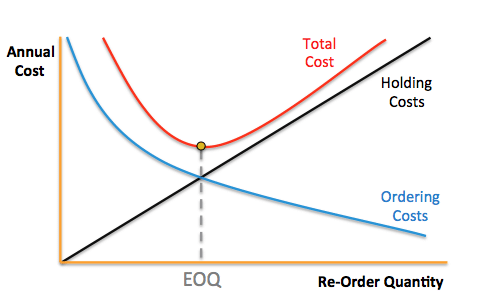

3. Economic order quantity (EOQ)

Economic order quantity is a formula used to calculate the ideal order quantity a company needs. It includes total costs of production and consumer demand. This technique is used by businesses to see the minimal amount of inventory they can buy, while keeping the business ticking over. It helps to free up cash when it’s needed most.

The formula is:

EOQ = √(2DK / H), or the square root of (2 x D x K / H)

D = Order costs (per order)

K = Demand rate (per year)

H = Holding or carrying costs (per unit, per year)

The graph below demonstrates the EOQ equation:

Image: Medium.com

4. ABC analysis

This inventory management technique splits products into three categories to help better organize your stock, and identify those items that cost the most to store. It also helps you manage the profitability of the items based on their category.

- A – The most valuable products that you generate the most profit from.

- B – Products that aren’t the most valuable, but also not the least valuable. They fall somewhere in-between.

- C – The least valuable products that help to generate a small, steady profit.

5. Minimum order quantity (MOQ)

The minimum order quantity technique is the smallest amount of stock that the supplier is willing to sell. For example, if you’re trialing a new product, you may not want to invest in large quantities until you know how much demand there is from the consumer.

Higher-priced items usually have a smaller MOQ because they are typically more complex to make. Smaller, cheaper items usually have a high MOQ because they’re cheap to make.

6. Just in time (JIT)

The JIT method is all about minimizing the amount of space your inventory takes up in the warehouse. One of the downsides is that it is risky, because if the product doesn’t arrive on time, you’ll be left with some unhappy, frustrated customers.

The car giant Toyota experienced this first-hand. They first adopted a JIT inventory control model in the 1970s, but in 1997 the manufacturer of their brake valves was hit by a fire that destroyed all their stock. This meant Toyota had to find an alternative supplier quickly. They were forced to shut down for two days which cost them $15 billion and 70,000 cars.

If you can find a balance between waiting until the last minute to replenish products and avoiding a stockout situations, then JIT can be effective. However it may not be possible for certain products with a long lead time.

7. Radio frequency identification (RFID)

RFID allows a business to track products as they make their way through the supply chain. Using radio waves, products can be located via a tag and a reading device. The tag is a small microchip, so it’s easy to install and lightweight.

The tags are then fixed to the pallet or truck as it makes its way from manufacturing to the retailer. The tag can then emit radio signals that the reader collects. The reader is kept at the warehouse for management teams to keep an eye on incoming inventory.

When asked ‘What challenges do you face helping your retailer customers with cross-border ecommerce?’, 29% of supply chain managers who deliver goods across borders felt that tracking deliveries was challenging. RFID helps with this, which is why it can be such a vital part of inventory control.

8. Bulk shipments

Bulk shipments can be preferable for large businesses that typically have a high turnover of stock. It’s often cheaper to buy in bulk, and you also need to buy less often because you have everything you need in the warehouse until stocks run low.

However, one of the downsides can be that it costs more to keep stock in the warehouse as it takes up more space. If the product is selling fast, though, it may not stay in the warehouse for long.

How Will You Manage Store Inventory Control?

Inventory control is vital for keeping your business running smoothly. When there are issues with your warehouse or inventory levels this can cause delays, which is bad news for your customers.

By investing in smart software like Brightpearl, you’re able to optimize your workforce and manage inventory right through from purchase to sale. It also includes automated multi-location inventory tracking so you know when to expect your next shipment. So, if you’re implementing any new store inventory control procedures in your business, be sure to use the best software to support you and your employees.