For medium to large e-commerce brands and wholesalers, inventory planning comes with additional complexity. You may be operating across multiple online sales channels as well as physical stores in various locations. You may have a large database of customers or be looking to scale up operations in the near future. Plus, sudden market shifts can add an extra layer of complexity to your inventory planning.

Whatever your growing business looks like right now, pinning down a successful inventory plan and management strategy is essential for your future security and success.

Efficient inventory planning and assortment planning offers a fast route to reduced costs tied up in dead inventory, optimized product mix, happier customers, and increased revenue and profit.

But despite the business-critical importance of proper inventory planning, all too many businesses today are not doing everything in their power to plan appropriately.

We want that to stop.

This article will cover everything a fast growing e-commerce retailer needs to know about inventory planning. From what it actually is, to the best technology for the job. What questions should you be asking yourself? What planning method is right for your business?

By the end of this article you’ll be able to answer all of these questions and then some.

It’s time to end shoddy inventory planning and ensure that our businesses are streamlined for the future.

So, let’s get started.

What is Inventory Planning?

Inventory represents often the biggest part of a retail business’s assets – up to 80% of cash is usually tied up in inventory. Holding inventory is unavoidable as it allows organizations to operate continuously. However, having too much inventory is damaging to a healthy cash flow and holds business growth as the money tied up in excessive inventory can’t be invested in other areas of the business.

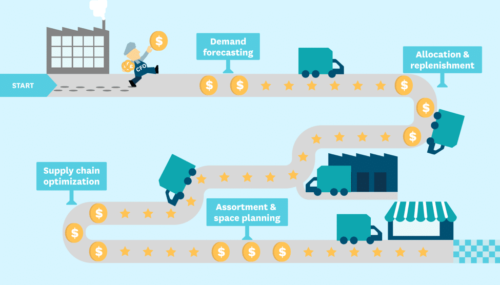

Inventory management planning is an integral part of a company’s supply chain management strategy, alongside order management, accounting, warehouse operations, and customer management.

Inventory planning involves forecasting demand and deciding exactly how much inventory and when to order. When done successfully, this helps companies meet demand whilst reducing expenditure.

In other words, by having just the right amount of inventory at the right time, in the right location, businesses reduce the overall cost of storing merchandise, optimize inventory allocation routes, and ensures that there is always the right amount of stock to meet customer demand (whilst avoiding surplus stock in obsolescence or overstocking).

Image: Shopify

As a result inventory planning improves customer satisfaction rates by preventing overselling. Consistent service levels also breed loyal customers.

In order to establish a reliable inventory planning, businesses and organizations must do three things. These are:

- Demand forecast: using historical sales data, KPIs and variables like seasonality, promotions and market predicts to make data-driven forecasts.

- Control costs: considering things like choosing the right suppliers, automating purchase order process, reducing cash tied up in slow-moving products etc. –

- Store efficiently: storing the right amount of products in the right place to optimize your order fulfillment routes if you have multiple inventory locations

When these three workflows exist in tandem, inventory flows continuously, seamlessly, and efficiently. But, of course, maintaining such a complex operation comes with some challenges.

Differences Between Inventory Planning and Assortment Planning

Inventory planning is all about optimizing your inventory levels so that you minimize costs but always have enough stock to meet demand. It involves making strategic decisions on when to reorder and in what quantity.

Effective planning requires you to make accurate forecasts by analyzing sales history and emerging trends. You also have to ensure adequate storage for the goods, and understand how factors like supplier lead times and availability of raw materials affect the supply chain.

There is some crossover between inventory planning and assortment planning. Both are reliant on data regarding customer behavior, trends, and product performance. And the aim in both cases is to maximize profit and deliver a great customer experience.

However, assortment planning is more specific. It’s about choosing the range (or “assortment”) of products you want to sell at particular times, and deciding which ones will be sold via which sales channels. This is based on seasonality and demand for each channel or location.

Assortment planning helps you rationalize your SKUs and focus your investments on items likely to bring in the most revenue while avoiding those for which demand is low. You can also plan your inventory around warehouse capacity.

4 Challenges of Inventory Planning

Inventory planning involves bringing together lots of different factors and variables. Planning inventory accurately can be challenging even for businesses operating on one sales channel.

When a business or organization relies on multiple channels, with multiple warehouses, and possibly even multiple 3PL providers, things get even more complex. Especially when demand fluctuation and seasonality are also added into the mix.

Dealing with so many separate operations and variables at once poses some unique challenges. Even small hiccups can spell disaster. Typical challenges include:

- Disparate data

Effective inventory planning requires a lot of data from a lot of places. And bringing all this data together is a complex task. Inventory planners will need to collate historical data and retail reports that may be dispersed across many different legacy systems.

Planners will need to collate sales orders, accounting, fulfillment, suppliers and point-of-sale (POS) data.

This is not only time consuming but, if done poorly, may result in biased demand forecasting leading to over-stocking, under-stocking, or missed opportunities.

- Guesswork

Making predictions is never easy. If you don’t have the right KPIs in place to guide your inventory planning, guesswork will always be there, even if you have analytics tools. Plus, unpredictable market variations can make the forecasting even more complex.

2020 was a testament to that very fact.

- Multiple locations

Allocating inventory that is stored across multiple locations is challenging. Without a suitable inventory tracking system, it’s difficult to know exactly where to allocate your merchandise all the time.

Plus, storing merchandise in the wrong place could result in added shipping costs and longer wait times for customer order fulfillment. A poor picking process will not only reduce productivity, but increase travel times across the whole supply chain.

- The human component

Technology is not the whole solution. Inventory management planning is ultimately controlled by an inventory planner. When the role is taken over by somebody else, there is a lot of historical knowledge that needs to be transmitted to the new person in charge.

The new planner will initially lack the brand awareness of the outgoing planner and may struggle to understand the historical reasoning behind the current inventory management system.

And the human component doesn’t just apply to senior staff. Even with the best inventory software in tow, if staff aren’t sufficiently trained to use it, your business won’t see the best results possible.

Poor training impacts management and breeds miscalculation. Likewise, poor communication between procurement, production, and quality control departments will ultimately impede efficiency.

Why Inventory Planning is Essential for E-Commerce

Inventory planning and control is the pillar of successful e-commerce. That’s because a business without a solid inventory plan or inventory planning solution to support it is significantly more vulnerable to overselling, understocking, and delayed order fulfillment. At the end of the day, this all comes crashing down on customer experience.

1. Avoid overselling

Overselling is harmful to customer experience and is often a cause of bad reviews. Customers are less likely to return for repeat purchases and will take their custom to your competitors.

2. Release cash

When too many slow-moving products accumulate in the warehouse, e-commerce retailers are often forced to discount or liquidate in order to release this excess of cash held in stagnating merchandise, in order to invest in more profitable products

3. E-Commerce is booming

78% of people are set to increase their online purchases over the next year. To meet this increased demand, e-commerce retailers will need to scale their inventories with effective and flexible planning.

4. Meet customer expectations

Customers’ expectations are always high on e-commerce brands, even during the pandemic. Since the COVID-19 crisis, up to 36% of customers have reported being let down by online orders. More and more customers are turning to online reviews before buying, and more than three-quarters admit to leaving negative reviews following a bad shopping experience.

Dealing with negative reviews costs serious money. Money that could be easily saved by avoiding these problems in the first place with robust inventory planning.

Effective inventory planning can meet customer expectations by offering the right products, speeding up the order processing time, eliminating avoidable mistakes that cost a business time, money, and brand reputation.

By investing in appropriate e-commerce inventory planning software and experienced planners, retailers can avoid these money-draining situations and boost their customers’ experiences. Effective, data-oriented, planning helps retailers reduce time, scale, and optimize product allocations and pricing.

Considering the unexpected nature of the Pandemic, it is possible to understand why retailers were taken by surprise. But the crisis has taught us all some valuable lessons as well.

Retailers with flexible, scalable, inventory management plans already in place were able to meet accelerating customer demand head-on. Now there’s no longer any excuse.

Ask yourself, is my business post-pandemic proof?

The Pandemic has shown us, first-hand, the importance of maintaining an inventory plan that is robust enough to succeed through unforeseen events.

In fact, according to a 2020 survey by Statista, roughly one-fifth of businesses plan to have more inventory in the aftermath of the pandemic, whilst 27% state that they will be making adjustments to their supply chain networks.

To sum up, inventory planning will help you:

- Reduce stockouts

- Reduce overstocks

- Optimize inventory locations

- Rotate stock faster

- Increase cash flow

- Increase profitability

- Easily retrieve items

- Reduce guesswork

- Prevent order processing delays

- Anticipate lead times

Key Considerations for Building an Inventory Management Plan

Given that proper inventory planning is so business-critical – now more than ever- what can we actually do to ensure that our inventory plans are robust and ready to go?

To actualize and carry out a successful inventory plan, you’ll want to follow some best practices and procedures. In order to do this it’s imperative that e-commerce businesses familiarize themselves with the important steps involved when it comes to planning inventory.

The important steps involved

There are many important steps involved in planning and executing a successful inventory plan. In general, these roles can be thought of in three parts: context; analytics; the planning.

Context refers to your business’ data history. From micro details to macro level planning. Everything from sales orders, customer knowledge to the competitor landscape and current socio political events should go into informing your inventory planning process.

Analytics refers to inferring information from the data itself. Ensuring that the inventory plan is based on the correct data, sufficient data, and (extremely important) complete data. What does this data mean, and how will it inform a flexible, scalable inventory plan?

Finally, the planning stage is absolutely critical in and of itself.

The planning stage involves:

- Gathering a comprehensive database of historical sales data

- Understanding how stock keeping units (SKUs) have performed

- Using SKU performance to set expectations for upcoming seasons

- Analyzing the competition’s data (pricing, promotions, & trends)

- Setting tentative or strict receipt budgets by product category

- Weekly performance recaps to assess product and category performance

- Setting markdowns and promotions based on weekly performance recaps

- Reforecasting periodically based on weekly updates, trends, and current events

- Managing evergreen inventory with monthly sales forecasts and receipt projections

- Post-season hindsighting of financial and product performance to determine if targets were met and make necessary changes to next season’s strategy

Setting up best practices and procedures

Another key consideration when it comes to inventory planning is maintaining best practices and procedures at all times. Getting inventory planning right is a balance between human expertise (people), intelligent strategizing (process) and the right tools for the job (technology).

When starting to develop an inventory plan, it’s a good idea to ask yourself some rudimentary questions that will inform your strategy going forward.

1. What is your product volume likely to be?

To answer this, dedicate some time to look into your historical data to understand the seasonality, coupling with trends data from tools like your own inventory planning software or Google Trends. Do this before scheduling any orders.

You’ll be able to calculate your regular off-peak sales stock requirements as well as factoring in any anticipated demand spikes. By determining your economic order quantity you’ll identify the optimum quantity of stock to hold at one time and minimize total ordering and holding costs accordingly.

2. What might impact my inventory?

It’s important to anticipate any internal or external factors that might impact consumer demand in the future. Consider retail inventory planning variables such as upcoming advertising campaigns, sales promotions, target market, seasonal demand spikes, and current consumer trends.

3. Am I prioritizing efficiency?

Efficiency is the lifeblood of inventory planning and control. Ask yourself if your warehouse and order process is streamlined for optimal performance. If not, what can you do to make sure that it is?

Think well-organized storage spaces for easy picking and retrieval, sufficient space for extra stock (but not so much that you’re hemorrhaging money), optimal warehouse locations for faster delivery fulfillment, and streamlined communications between inventory and order management teams.

4. Am I using the right KPIs?

Consider whether you’ve been using metrics and key performance indicators (KPIs) to your full advantage. These critical datasets help organizations gauge the success of their inventory planning to date. Make sure that your inventory plan takes the following factors and variables into account – and use KPIs to inform your future strategy.

- Orders delayed by stockouts

- Storage capacity usage

- Forecast accuracy

- System accuracy

- Daily sales

- Movement of inventory

- Customer satisfaction

- Inventory turnover

- Carrying cost of sales

7 Common Inventory Planning Methods

Inventory planning and control systems won’t look the same for every business. As such, there are various different inventory planning models. In fact, there are three main examples of inventory planning methods.

The models meet the needs of different types of companies. Primarily those dealing in:

- Raw materials

- Partially completed goods

- Finished goods

The Deterministic Inventory Model

The deterministic inventory model is most typically used by merchants dealing in raw materials. The deterministic model uses a precautionary method to avoid stockouts. One example is the Economic Order Quantity (EOQ) model.

With food inventory planning software, for example, the EOQ model can be used to calculate an optimal order quantity to reduce inventory costs and maximize value. This is an effective model as long as demand stays relatively steady. But it does not account for seasonal change or external fluctuations. The deterministic model, therefore, requires constant monitoring to be successful.

The Work in Progress (WIP) Model

This model is best suited to merchants dealing in partially completed goods, finished goods, or goods-in-transit (GIT). This inventory model focuses on the holding of inventory and there are three motives for doing so.

The transaction motive posits that buying raw materials in bulk is cheaper and brings down the per unit cost. The precautionary motive uses inventory as a protection against demand uncertainties to prevent stockouts. The speculative model promotes holding inventory to mitigate increases in the price of materials and/or labor.

The Perpetual Inventory Model

The perpetual (or continuous) inventory model is also often used by companies dealing with partial or finished goods. Continuous systems constantly track quantities, and replenishment orders are made as soon as stock reaches below a set cutoff point (the reorder point).

This is the only system that cannot be maintained manually. The perpetual model relies on specialized technology. But this model allows merchants to keep track of current stock levels and avoid stockouts.

The Just in Time (JIT) Inventory Model

The just in time (or JIT) inventory model works by aligning orders of raw materials or items from suppliers with production schedules directly. In other words, the company will hold sufficient inventory to cover maximum market demand.

The idea is to increase efficiency and decrease waste by ordering and receiving goods as and when needed, and never in surplus. To achieve success with this model, therefore, retailers must make sure to forecast demand as accurately as possible.

The FIFO & LIFO Model

FIFO and LIFO are both common techniques in inventory control and planning. FIFO (first in, first out) means that you fulfill orders using the oldest products first. This is ideal for perishable goods with expiration dates, but it also guards against obsolete stock that’s gone out of season or fashion.

LIFO (last in, first out) is the opposite. It’s mainly used by companies who want to use current prices to calculate the cost of goods sold as this offers tax advantages when prices of goods are rising.

The Minimum Order Quantity Model

Minimum order quantity (MOQ) is basically the lowest number of units that a supplier will sell to a buyer. Many suppliers choose to set an MOQ because it’s not cost-effective for them to sell you just a handful of items—it’s only worth their while to sell in larger quantities.

Cheaper items generally have a higher minimum order quantity, enabling wholesalers to sell items at a cheaper rate. However, buying in bulk can mean the buyer risks overstocking.

E-commerce retailers may use MOQ to set a minimum spend threshold for customers in order to offset the costs of offering free shipping.

The Reorder Point Model

This is the point at which you need to replenish stocks of a given item to prevent a stockout. This will be different for each product line because it’s based on supplier lead time, warehouse receiving time, and safety stock protocol. You can use demand forecasting to predict how quickly an item will sell.

Here’s the calculation: Reorder point (ROP) = demand during lead time + safety stock

Inventory planning software typically lets you set a reorder point per item and sends you a notification when stock levels are approaching it. Some systems will even order new stock automatically, based on your rules.

Best Inventory Planning Software Options

Brightpearl

Brightpearl is a cloud-based retail operating system that combines inventory management, demand planning, order fulfillment, warehouse management, purchasing, accounting, CRM, and POS in a single platform.

Advanced reporting helps you make data-driven forecasts based on sales history, product performance, and customer behavior. Data is synced across all channels and locations for a real-time overview of inventory levels—and you also receive replenishment reports and low-stock alerts.

Aside from planning, Brightpearl’s automation engine lets you automate your workflows (and reduces human error by 65%). It covers everything from complex order fulfillment to auto-generated pick lists and POs, plus barcode scanning.

The platform integrates with top marketplaces, platforms, shipping carriers, and 3PL providers, with the core integrations all built, developed, and supported in-house.

Brightpearl is made especially for retail, so it has all the features you need without charging for those you’ll never use. It’s also designed to scale as you grow—add as many new sales channels and users as you need, at no extra cost.

Pricing is tailored to your order volume, . Full advanced support is provided in your standard Brightpearl subscription, with business consultants and training included.

NetSuite

Oracle NetSuite is a modular ERP with plenty of features, including inventory tracking for multiple locations, forecasting, cycle counting, reorder points, and lot and serial tracing. You can automate core processes and get real-time insights into operational and financial performance.

One major downside is that those features come with a steep learning curve. And because NetSuite isn’t retail-specific, it’ll need modifications to tailor it for a retail business. The one-size-fits-all model means you’ll be paying for features you don’t need. There aren’t many integrations, either.

Users pay an annual license fee for the core platform, the number of users, and optional modules—plus an implementation fee. (The setup takes 420 days on average, compared to Brightpearl’s 90.) You can add more modules and users for an extra charge.

That’s probably why reviewers say NetSuite is expensive, especially since you have to pay extra for full support. Users also mention the learning curve and difficulties with customization.

Infor

Infor offers a huge array of products, which can make it tricky to select the right one. For example, there are various ERPs for different industries. If inventory planning is your main concern, you’ll probably need the Infor Supply Chain Planning suite.

This includes modules for demand planning, supply planning, production planning and scheduling, inventory optimization, and integrated business planning. It’s designed to allow companies to create, manage, collaborate, and coordinate plans across their supply chain.

Infor helps with safety stock strategies, assortment management, and inventory optimization, and lets you synchronize production with demand. You can follow real-time changes to adjust forecasts. The system learns as new data becomes available and shows you how to respond to market shifts.

There are no plans or pricing displayed on the website, but some users mention that implementation can be costly. Reviews also cite a learning curve with lots of training needed.

SAP

SAP also has a wide product range, with at least two possibilities for inventory planning. There’s SAP Integrated Business Planning or SAP Cloud ERP (also referred to as SAP S/4HANA Cloud, available in public or private editions).

The IBP software encompasses supply chain-related financial forecasting and scenario planning, alongside statistical modeling, advanced demand sensing, and response management. Various plans are available within the product—inventory is listed separately from demand, and all are “price on request”.

SAP Cloud ERP offers live inventory management, warehouse management, transportation management, and personalized business insights. It helps you adapt to changes based on real-time usage and customer experience data, and it allows you to integrate barcode and RFID technology.

No pricing information is shown, but reviews mention it’s expensive as well as complex to implement. Some users say it’s not very user-friendly, requires modification4, and that integration is tricky.

Blue Yonder

Blue Yonder’s product is called Luminate, which is divided into several categories. Luminate Planning describes itself as an end-to-end supply chain solution. This provides machine learning-based recommendations and predictive analytics, enabling you to see potential disruptions and opportunities, and to pivot your plans if needed.

The software also includes real-time order, shipment, and inventory status to inform your planning decisions. You can run scenarios, optimize your inventory, and coordinate order-to-delivery operations.

Seemingly a separate product, Luminate Commerce also has inventory planning and management capabilities alongside order fulfillment. And Luminate Logistics includes warehouse and transport management.

With no plans or pricing shown, it’s hard to know exactly what you’re getting, or if it’s possible to combine these solutions. Reviews mention a confusing interface and that the product takes a while to set up.

How to choose the right inventory planning tools

The features you want from an inventory planning solution will vary from business to business, so think carefully about current and future requirements. An all-in-one platform provides value for money, but be wary of non-specific ERPs that require customization and charge for elements you don’t need.

That brings us to ease of use—look for software that’s simple to set up and use, with fast implementation. It should also be easy to integrate popular platforms and favorite tools.

It’s important to have robust support, preferably included as standard. Discuss your requirements with the vendor before signing up, and ensure you know exactly what you’re getting. Brightpearl gives you retail-specific features, fair pricing, and a user-friendly interface.

Improving Inventory Planning With Technology

Inventory planning can be improved, aided, and enhanced with the right technology. ERP inventory control systems offer users versatile inventory planning control over various parts of the product lifecycle. From production in the factory, to storage in the warehouse and transit. However, implementing an ERP system is often a complex project that can take up years, and usually requires customized e-commerce integrations at extra cost. So it may not be the ideal option for e-commerce businesses that look to expand quickly.

Though small businesses might be perfectly fine using Excel to manage their inventory, but can easily get overwhelmed by increasing order volumes and product SKUs when their businesses start to grow.

Luckily, there are many inventory planning control software options on the market today that can be scaled for different business needs. In fact, many of these software companies offer fully customizable enterprise-level software solutions, things like:

- Location management

- Sales tracking

- Barcode & POS capability

- Barriers to oversell

- Multi-channel management

- Data-driven demand forecasting

- Fulfillment planning

- Inventory, sales channel, supplier and customer reporting

- Retail business intelligence

Mobilizing technology and real-time data insights will remain key to managing customer expectations in the years to come, coping with demand fluctuations and surviving through any future supply-chain disruptions.

Digitizing our supply chains will help us future-proof our e-commerce platforms by speeding up business-critical processes and eliminating time-consuming manual tasks and decision making.

Introducing Brightpearl

Brightpearl offers a retail-tailored Operating System that is specifically built for omnichannel merchants and assists with retail inventory planning. Integrated POS syncs all your online and offline channels in real time for the ultimate in flexible and streamlined inventory management.

In other words, for medium to large retailers managing multiple online sales channels, Brightpearl’s inventory management software is designed to enhance operational agility, boost sales, and meet (or rather, exceed) customer expectations with data-driven inventory planning and workflow automation.

With this intuitive inventory planning tool, you’ll be able to manage your inventory across marketplaces like Amazon, your web stores like Shopify, BigCommerce, Magento , your physical stores and other major e-commerce platforms – all from one place.

Product performance analysis allows you to analyze products based on order volume, margins, revenue, and customer lifetime value to make intelligent data-backed business decisions.

In our fast-changing e-commerce ecosystem, you need to be armed with a system that can boost your operational agility to adjust quickly to any sudden market shifts, remain competitive and hold on to our customers throughout turbulent, fast-changing markets.

Frequently asked inventory planning questions

Why is inventory planning important for e-commerce?

– It reduces stockouts, improves cash flow, enhances customer satisfaction, and supports scalable growth.

Can you give an inventory management plan example?

– Yes, an example plan includes demand forecasting, supplier management, SKU performance analysis, and location-based stock allocation.

How does inventory planning differ from inventory management?

– Inventory planning focuses on forecasting and ordering decisions, while inventory management covers day-to-day tracking, storage, and fulfillment.