Inventory management is a central part of business administration and management. Your inventory doesn’t just impact your customer relations and customer service provision, it also has a direct influence on your business’s bottom line and forms an intrinsic part of your supply chain management.

These are just some of the factors that can come into play when businesses talk about inventory management and some of the reasons why good inventory matters. What other benefits can your organization gain from having good inventory management? And what are the most common mistakes that stand in the way of this?

This article will have a look at these and give you the best solutions so you can master this essential business skill!

Why Good Inventory Management Matters?

Good inventory management has an impact on all areas of your organization—from business costs to punctual order fulfillment. This makes it important to create a system that makes inventory management smoother and more functional. There are many ways to do this, the most popular being the use of software solutions.

But how can good inventory management benefit your business? Why does it matter? Here are a few good reasons to improve this aspect of your company management.

Inventory management techniques for cost reduction

Any worthwhile inventory management tool or structure should be able to conduct economic order quantity (EOQ) estimations. This helps you note the best cost-saving approach for placing orders. This technique compares the product storage costs against the product order costs. This way, you can reduce your warehouse or storage fees by managing product levels in a way that cuts your storage costs.

Inventory management strategies to increase profits

When you have products that aren’t selling just sitting in your warehouses, then your business makes a loss. You’ve forked out money buying or making the products but you don’t get returns on that investment. With forecasting as part of your inventory management, you can decrease the risk of unreturned investments by monitoring the number of sold items and estimating how many sales you may make in the future.

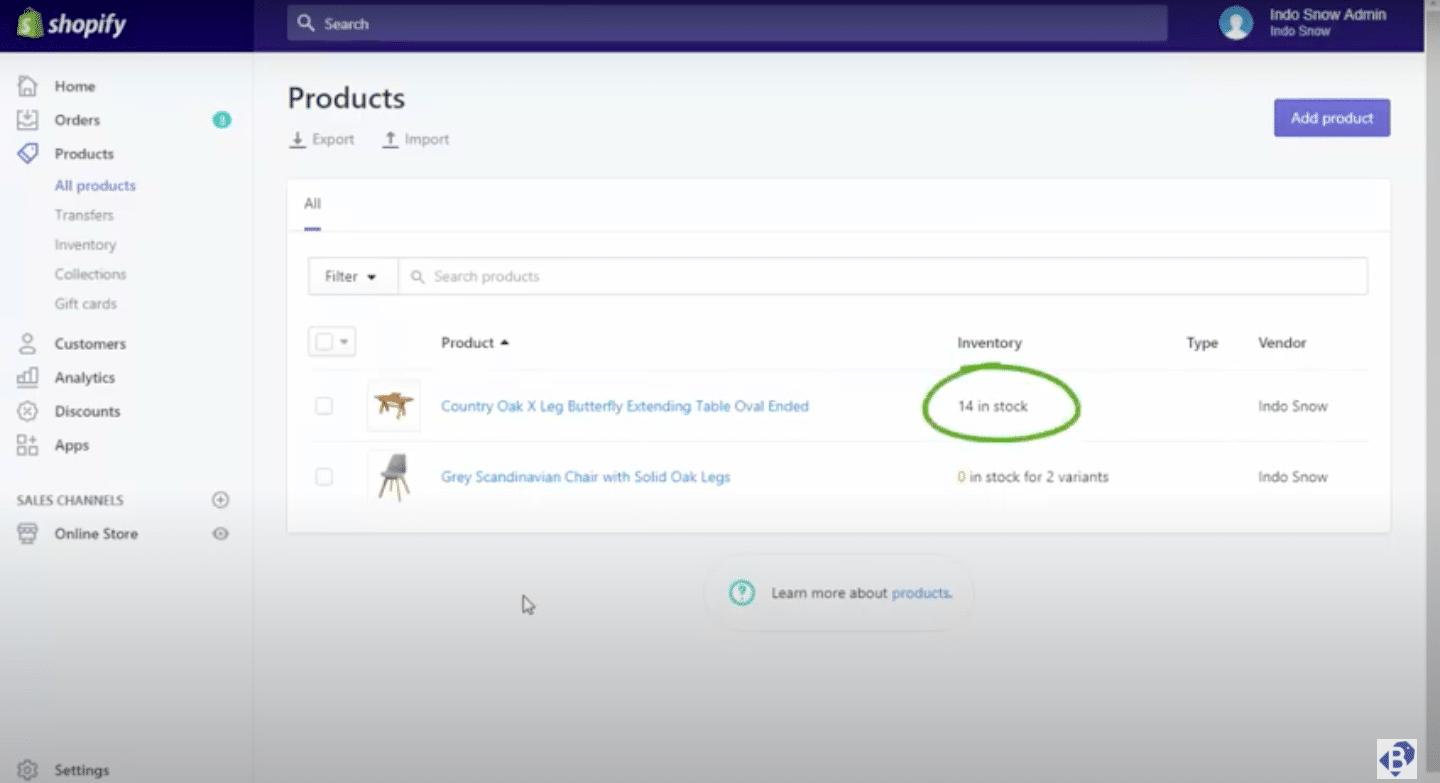

Good inventory management software will also automatically update your stock levels with each sale or order, ensuring you don’t buy too much product. We’ll discuss this more when we look at some of the mistakes people make with inventory management and the solutions that exist to address these mistakes.

Automated inventory management for better stock availability

There’s little worse than going into a shop (whether online or brick-and-mortar) with your heart set on an item only to find that it isn’t available. Very few customers in this situation tend to stick around and browse for an alternative item to purchase. Most, simply do a runner to try and find it somewhere else. If this happens repeatedly, then you might find customers no longer visiting your store at all.

Inventory management helps you monitor your stock levels and order the right stock numbers to cater to your customer demand, helping you make sales now and keep customers coming in the future. Furthermore, if you have many sales touchpoints or many points of sale, then inventory management makes it easier to keep tabs on all the sales coming in from different channels.

Good inventory management speeds up order processing

Great inventory management includes warehouse and order management. With warehouse management, you can keep an organized and clean storage space, ensuring product quality and minimizing the chance of lost packages or stock level miscounts. Furthermore, it makes it easier for your workers to select the right merchandise to match customer orders, ensuring the dropshipping model you use delivers exactly what they paid for.

On the order management front, it doesn’t make sense to record phone conversations so you can remember what orders you have open. Rather, you can use your inventory management to make certain that you fulfill orders in time by tracking the order process accurately. Thus, you ascertain that your customers get what they ordered and that they get it on time.

Improves customer service

You can see above how product availability has a direct impact on customer satisfaction and loyalty. It’s also clear how speeding up order processing leads to better customer experiences as buyers can get their items quicker.

Better order processing, product availability, and customer service all contribute to a better customer experience and loyalty to your business. Thus, inventory management has just as much of an influence on your customers as a quality monitoring call center might, for example.

Promotes better use of storage spaces

Clearly, inventory management helps with warehouse organization. It allows you to make sure your storage spaces function more efficiently by analyzing space, considering pallet sizes, calculating the cost per square foot of space, and helping you find cost-saving storage methods. Some inventory management software also includes barcode scan systems that can help with monitoring inventory levels, reducing inaccuracy.

Eases functionality

Overall, setting up an inventory management structure, tool, or software can assist you tremendously in coordinating all the elements above, especially if you have numerous sales platforms. You improve your business’ productivity and functionality and streamline inventory activities for the better of your business!

7 bad inventory management mistakes and how to fix them

1. A lack of performance standards

It’s hard to address issues or problems when you have no clear standard to measure them against. While being aware that there are issues is a start, knowing what the ideal standard is means a whole different thing, and this is something that businesses tend to overlook.

You need to have measures in place to monitor whether your storage spaces are functioning efficiently, or your order management is good enough, for example.

The solution:

Implement Key Performance Indicators (KPIs) that will help you track whether you are meeting the performance levels that optimize your inventory management. For example, you can choose to track your fill rate and inventory movement. That way you can track the number of orders, stock coming in and stock going out to fulfill these orders.

Once you’ve decided on your indicators, it becomes easier for you to track metrics that show you whether your inventory management is performing as you would like it to.

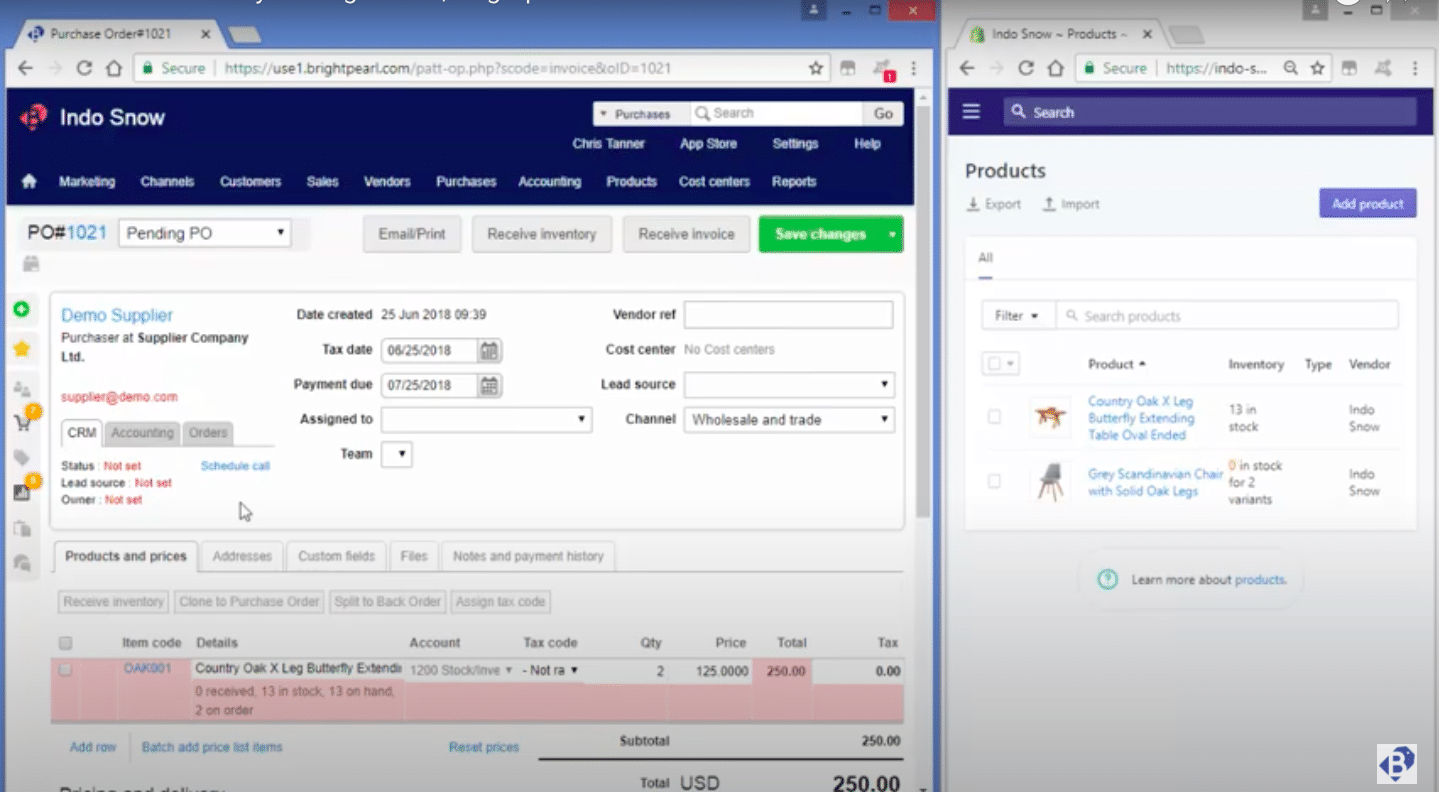

2. Overordering/overselling

Imagine this: your business has been doing extremely well with orders coming in every day. Your products are exceptional, customer reviews point to customer satisfaction and sales are out of the roof… That is until a customer tries to place an order and you realize you no longer have any more stock available. You’ve oversold!

On the other hand, there’s a product that hasn’t been doing too well but you didn’t notice that and now you’ve got way too many units untouched and unmoving. You’ve over-ordered!

These are two distinct scenarios and mistakes but both come from the same core issue: a lack of foresight.

The solution:

- Using robotic process automation for better inventory updates.

- Barcode scanning features for instant and real-time inventory checks.

- Forecasting for more efficient and more accurate stocking decisions.

3. Bad inventory planning/no demand forecasting

It’s a huge problem if you have no sense of your stock levels, whether current, past or upcoming. You need to have a clear overview of how your business is performing and what implications this has on how much stock is available and how much you ought to order in the future.

Discrepancies in stock levels can affect your employees as they struggle to meet customer needs and orders. Of course, poor stocking will also affect customers and your ability to give them the best service. All because you fail to plan and monitor your inventory levels.

The solution:

Forecasting helps you anticipate the amount of product you may need in the future—as a product feedback survey can. It takes into account past and current product performance to give you accurate information that helps you make better stocking decisions. Furthermore, with the automated capabilities of many inventory software solutions, you can receive updated reports generated from product trends and stock levels so that you’re in the know about what your customers like.

4. Unqualified inventory management

It’s not easy juggling customer demands and operations with the need to train new workers in inventory management. As a result, many organizations overlook the importance of training employees on how to manage inventory—a huge mistake!

The solution:

It may be a good idea to hire an inventory management team or manager who already has experience and training in this field. That way, you don’t have to worry about giving them too much training, other than looping them in on company-unique approaches.

Having a manager also means you know exactly who is responsible for inventory and who can be held accountable if things go wrong. Of course, if you introduce any new software solutions, it may be a good idea to educate all relevant employees on how it works for better implementation. With an online video call, you could even make this a time-saving virtual training.

5. Not using automation

If your organization still uses spreadsheets or other manual input methods for stock-taking and inventory tracking, then you sacrifice time, money, and efficiency. Plus, this is a mistake that can lead to other mistakes. Not using automated inventory management features makes it more plausible that there will be errors in your inventory data.

Not only is there human error at play, but if you have a large business, this could take a very long time to do!

The solution:

Utilize inventory tools with automation capabilities to optimize your operations, saving time, money, and resources. Workers can receive instant updates, and simultaneous data access—kind of like a simultaneous ring. This will also boost efficiency leading to faster order management and fulfillment and, consequently, happier customers!

6. No system for inventory counts

Uncoordinated inventory counts contribute to a lack of information about stock levels, poor stock availability, and the inability to fulfill orders efficiently and accurately. This is something that should be done on a daily basis for consistency and accuracy. However, you sacrifice both if you try to do inventory counts manually!

The solution:

Save time and money by using an inventory system with barcode scanning capabilities. That way you can conduct inventory counts faster digitally.

7. Poor warehouse management

It’s easy to think that in order to have access to more inventory when you need it, you should have more storage sites to keep it in. Wrong! Storage management is not about how much space you have, but how efficiently you utilize the space that you do have.

Do not make the mistake of having too much storage space or too many storage sites. Not only is it more costly and more difficult to manage and sync data from many different sites, but it can also lead to you becoming lenient about getting stock out as you have the space to house it.

The solution:

Centralize your inventory Try and keep your stock in central storage spaces for easy access and easy management. You also want to make sure that the space itself is used to its optimum capacity. Of course, you don’t want to squeeze so much stock in that it becomes a safety hazard, but you also don’t want any wasted space. Your inventory management software can make this easy to calculate and manage.

Implement inventory management strategies for long-term success

Any business worth its weight in gold should understand the importance of monitoring its inventory, and prioritize the implementation of efficient inventory management techniques. Of course, all of this can be achieved in remote and hybrid settings through a business phone system or any internal communications tool. Without a good inventory management approach, you’re more likely to make mistakes, you sacrifice time, money, and resources, and you compromise customer service provision.

Of course, even with an amazing inventory management system, there will be flaws, but the benefits you get from having one are notable. You reduce the margin for error, automate processes, plan better with forecasting, track levels more seamlessly, and improve customer satisfaction and loyalty.

Inventory management matters and now that you understand why and know how to address any mistakes your business may have been making, you can improve your business functions. You will see the results immediately and—if you need any more motivation—so will your bottom line!