E-Commerce is one of the fastest growing sectors globally. Worldwide e-commerce sales in 2019 came to a total of USD 3.53 trillion and are expected to grow to USD 6.54 trillion by the end of 2022. And while the COVID pandemic devastated many industries around the world, it has given the e-commerce sector a further, dramatic growth spurt.

As an e-commerce retailer, your customers are the lifeblood of your business. Their journey with your organization can lead to customer loyalty and also new customers via their reviews and recommendations. It’s a journey broadly composed of two main sections; the buying experience through your online store and the post-purchase experience.

At the purchasing stage, you interact with customers through your website, any apps you sell on, and your various social media platforms. Integrated technology drives that interaction at every point, from initial browsing of your products to the checkout processes through your shopping cart . But once they have made a decision, and pressed the ‘buy button’, the journey moves to the post-purchase stage, starting with order fulfillment.

What Do Customers Expect?

With e-commerce giants like Amazon raising the bar when it comes to same-next day delivery expectations, efficient and successful order fulfillment is now a vital part of being a retailer today.

Whereas nine years ago, customers would happily wait 5.5 days for items to be delivered to them, customers now expect their items within 48 hours on average; with 88% of consumers also willing to pay for same-day or faster delivery.

The ability to satisfy a customer’s needs through the order fulfillment process can greatly affect whether a customer even places an order with you, both now and in the future.

In fact:

-

72% of shoppers value on-time delivery as the primary reason to frequent a retailer above all else

-

38% of shoppers will never shop with a retailer again if they had a poor delivery experience

-

25% of shoppers have canceled an order because of slow delivery speeds

Yet, despite the apparent opportunity that can come from an effective e-commerce order fulfillment process, we’ve found that ‘Goods not arriving on time’, ‘Item not arriving at all’ and ‘Lack of delivery updates’ remain the highest causes of dissatisfaction among consumers of all ages.

But just what is order fulfillment? How does it work? How can you make it work for both you and the end customer? And what part can technology play in enhancing the process and journey, and ensuring that the customer is satisfied?

What is Order Fulfillment?

At its simplest, order fulfillment is the entire process that happens from the point a customer orders and makes a purchase, to the point where that product is delivered to them. It is a process that may be facilitated by the retailer themselves, or it may be outsourced to a third party logistics (3PL) provider or specialist order fulfillment company. It is arguably the most essential process for any e-commerce retailer.

The order fulfillment process starts long before a purchase is made. Now it’s time to start the fulfillment clock ticking.

6 steps in the order fulfillment process

A smooth and integrated order fulfillment process works best for all parties involved (retailer, customer, 3PL, etc.). The most efficient order fulfillment process also involves the use of technology at every stage, from customer purchase to the final delivery. There are six principal steps in the process:

1. Receiving goods

Remember that the plans for order fulfillment need to start before customers even add products to their shopping carts. The retailer needs to either stock up on inventory in their warehouse or to send inventory to their chosen order fulfillment partner.

How much of each product is stocked or sent as inventory will depend on expected and forecasted demand. For some products, this may be dictated by seasonal fluctuations. For others, there may be a constantly high demand.

How a particular retailer or the 3PL provider deal with receiving goods may vary slightly, but most will follow a standard template at this stage:

- Goods are received. Staff count items to ensure numbers and descriptions match with details provided.

- Goods are inspected for any damage caused in transit.

- Stock keeping units (SKUs) are added to inventory management software or warehouse management software). In the case of a new product, an SKU is allocated.

- SKU numbers get recorded and checked. Barcodes and automation will often assist at this stage.

2. Storage

Once goods have been received, they are moved to appropriate storage. This may be standard storage (on pallets or shelves, or in bins) or it may be specialist storage if goods are cold chain products or have other specific requirements.

Inventory not only has to be stored properly, it has to be organized efficiently, too. Factors such as expiry dates or stock turnover (ensuring older stock is shifted before new stock) are crucial. Part of achieving this will involve the use of a good inventory or warehouse management system. Often it pays to prioritize high demand items when it comes to accessibility.

3. Picking

As soon as an order is placed online, and that information is communicated to your warehouse staff or fulfillment centre if you use one, the fulfillment process becomes more active.

In most cases, warehouse management software (WMS) will identify where products are located, as well as how many SKUs and units of each there are associated with each order.

A picker or picking team in your warehouses or at your 3PL select items according to a packing slip with the items, quantities, and storage locations. If you use a good WMS, the system will get updated in real-time to note the number of SKUs removed from their storage location.

4. Packing

Once the product has been removed from storage, it is moved to the packing area. Packing materials are selected to protect the goods and achieve the lowest practical dimensional weight. Some 3PLs will charge for packing materials, while others offer standard packaging for free. There may be a need for specialist or customized packaging in some cases, which will likely involve adding costs.

Specialist packing could include bubble wrap for fragile items, cartons, bubble mailers, etc. There may also be a need for designated packaging for some international deliveries. At this stage, the package will also be labelled and have packing slips added. That will include the delivery address and any necessary labels for international shipping.

5. Shipping

This can be a complicated but crucial step. As many as 75% of customers expect free delivery when shopping online, even on low value items. You 3PL partner may provide shipping, but are more likely to work with shipping carriers to ship your products. This could hinge on same day service or on the cheapest option.

As a retailer, you’ll likely offer different shipping options. Standard delivery may be free, but expedited delivery may incur premium charges. Most fulfillment service providers will use a logic based shipping system to identify the best carriers to meet any requirements for delivering your goods. Or, if you handle fulfillment in house, you’ll need to make similar calculations to streamline the delivery process for every order.

6. Returns

An e-commerce business’s returns policy plays a big part in customers’ purchase decisions. In fact, more than 60% of potential customers will look at the returns policy before choosing to buy. Returns at extra cost or a complicated return process may push your customers away.

Setting up a good system for exchanges and returns should be part of your initial negotiations with your order fulfillment service. You also need to make sure that your warehouse team or 3PL providers can handle return processes efficiently.

When a product is returned for exchange or refund, it must be quickly but carefully checked to ensure it’s appropriate to restock and the inventory should be updated instantly for reselling. If the product is in good condition, it needs to be routed to the optimal storage location.

The Challenges You’ll Face With Inefficient Order Fulfillment Processes

1. Wrongly filled orders

Wrongly filled orders typically occur because of human error. A simple mistake in inputting the reference number of a product can lead to the wrong product being picked and dispatched. Or it may even be a mistake at the point of picking the order from storage. Whatever the underlying reason, this is an error that can lead to an upset customer.

By automating more tasks for order fulfillment, there’s less room for error. Utilize inventory management systems and software that can automate as much of the fulfillment process as possible, to eliminate human error.

Another helpful way to reduce errors is setting up a strict quality control process. For instance, warehouse managers should review and approve the picking of high value orders. Even with automated order fulfillment software, you should set up rules for exceptional orders to be reviewed by humans before sending them out to customers.

2. Running out of inventory and risks of overselling

If your processes fall short of the mark when it comes to efficiency, then you’ll also fall behind the volume of orders you have to process.

Inventory won’t be allocated and reserved to orders in time, inventory levels won’t be updated across your sales channels, and you’ll likely oversell the inventory you do have.

Resolving overselling issues is still one of the core reasons why businesses consider retail operations software, like Brightpearl, yet it’s one of the easiest fulfillment challenges to overcome once this technology is in place.

3. Lack of scalability and revenue growth

Too much time and resource spent on inefficient order fulfillment also means less time for focusing on strategic initiatives that will drive traffic, brand awareness and ultimately, sales and revenue.

By gaining efficiency in your operation, you can easily move staff from the back office to the front of house.

4. Mismanaged sales order peaks

The holiday season, flash sales, and unprecedented product popularity have the power to make or break a business.

Handled correctly, these one-off shoppers could become loyal long-term customers; mismanage sales order peaks however, and it could be detrimental to your business.

The power to successfully handle sales peaks lies in the efficiency of your core operation so that orders only need to be handled by exception.

“While the overnight popularity of the product was obviously very exciting, the sudden and unexpected spike in demand left us with a dilemma of how to continue to operate without being completely overwhelmed. Fortunately, we’d recently moved to Brightpearl. The solution helped us to adapt and manage the surge in demand; processing thousands of orders without missing a beat. With our sales now coming into one central ‘hub’ automatically, it allowed us to view everything in one place, cutting down on admin time.”

– David Lochhead, Commercial Director, Finlay London

5. Slow time to ship

We already established in this article’s introduction that customers now expect to receive their items within 48 hours on average.

If you’re fulfilling all your orders manually and inefficiently, then there is little hope of adhering to these expectations – especially once you’re processing hundreds of orders per day!

This slow time to ship could also have the power to negatively impact your online marketplace seller ratings that call for fast shipping and great customer service.

“Automation has saved us so much time operationally. The main use we have for it is for allocating and fulfilling orders, which leaves our orders ready to print without any manual intervention. We’re now flooded with 5* Trustpilot reviews, most of which quote ‘fantastic, ‘great’ or ‘excellent’ customer service. We don’t just meet our customer delivery expectations, we’re now exceeding them, with an experience that both surprises and delights our shoppers. It has become a key competitive differentiator for our brand.”

– Andy Lockley, Head of E-Commerce, Love Shopping Direct

6. Dissatisfied customers and negative reviews

Overselling, running out of inventory, a lack of time spent on your front of house strategy, mismanaged sales peaks and a slow time to ship each have the power to upset your customers.

Put them together and this really could be detrimental to your business.

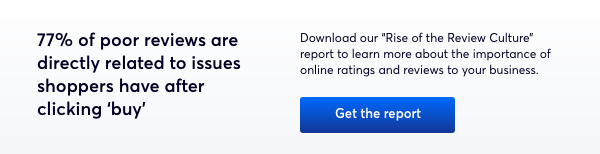

With customers now more likely than ever to leave negative reviews after a poor experience, your business must resolve these challenges and keep fighting fit against the Amazons of the world who are nailing it when it comes to a customer-first approach.

7. Multichannel fulfillment becomes nigh on impossible

Fulfilling orders manually on just one channel is complex enough as it is.

But multichannel fulfillment across different e-commerce platforms, online marketplaces and offline channels adds a whole new layer of complexity.

With multiple touchpoints, there are more opportunities for delay, human error and bottlenecks – and you risk losing control of your business.

You’ll need to have a centralized view of orders, instant inventory updates across all channels, perhaps even triggered by multiple warehouses, and the freedom to report on which channels are performing better than others.

These are just some of the challenges you’ll face without an efficient order fulfillment process in place; to address this, follow our best practice advice below for gaining efficiency in your operations.

8. Global shipping

Operating online gives you access to customers all over the world. But serving the global market presents its own set of challenges to order fulfillment. Shipping normally takes considerably longer, unless using a premium—and expensive—air freight service. And retailers should be aware that some countries have a less developed postal system that may cause issues.

It may help to restrict shipping to some countries. Whatever, always ensure that you’re transparent with international customers. Lay out precisely how much global shipping will cost, and what time frames you can work to. Make clear how international delivery affects returns and exchanges, too.

9. Communications

Having efficient communications at every stage of your retail to fulfillment process is integral to doing good e-commerce business. This, of course, includes how you communicate with customers via your various portals and platforms.

But for fulfillment of orders, ensuring there is clear and constant communication with your suppliers, logistics providers, and customers involved is also essential. It means that any issues are flagged and dealt with before they become big problems, and customer expectations are set to the right level

Order fulfillment models

There are a range of different order fulfillment strategies and models. Brands must choose those which suit their business model and also the needs of their customers. There will also always be the consideration of budget; what model best suits your current budgetary restraints? Remember, adopting one model now does not preclude a later change.

1. In-house

This model may suit both the very smallest and the largest and most established companies. It involves handling the whole e-commerce order fulfillment process yourself.

For a very small operation, order volumes may be so low that outsourcing order fulfillment is not cost-effective. Such firms may only be sending a handful of goods each week using shipping carriers such as FedEx. The largest companies, meanwhile, like to have oversight of the process from end to end.

When you look at an e-commerce giant such as Amazon, not only are all of their order fulfillment services in-house, they also offer fulfillment services to smaller retailers.

Pros

- Absolute control: In-house fulfillment provides the huge benefit of absolute control. You have a complete and transparent view of exactly how your fulfillment is handled and can change any part of your process as you see fit.

- Lower upfront costs: With the possibility of storing items at home when first starting out, and saving money that would otherwise be spent on outsourced services, in-house fulfillment often results in lower upfront costs.

- Accessibility: Providing there’s enough space somewhere for inventory and packing equipment, anyone can fulfill their orders from home. Making this route to transfer goods to market completely accessible.

Cons

- Time consuming: Packing and shipping orders yourself is hugely time consuming; time that could be better spent on sales and marketing initiatives instead.

- Long-term costs: While there are much lower upfront costs with this shipping model in place, it can become costly in the long-term, as you’ll need to consider additional warehousing and staffing requirements once your business hits larger order volumes.

2. Third party fulfillment

With this fulfillment system, an e-commerce organization will outsource the order fulfillment process to a specialist provider. They may choose to do this because they either simply do not have the space to store inventory or because they want to focus on other areas of their business, such as customer service or sourcing new products.

3PL providers cover all aspects of the fulfillment process, from the initial receiving of goods as stored inventory and the warehousing of them, through to the picking, packing, and dispatch of goods once ordered. In most circumstances, they will also enact any returns or exchange policies you have in place, to ensure an optimized customer journey from start to finish.

Pros

- Save time: You’ll instantly save time that would otherwise have been spent on packing and shipping orders. This time saved can be used to improve growth activities instead.

- Experience: Good 3PL suppliers have a wealth of experience when it comes to the order fulfillment process, ensuring your customers receive orders quickly and efficiently.

- Choice: Today, there are a number of 3PL companies to choose from. This is good news for you as you can decide which one is better suited to your individual needs and budget.

- Negotiated rates: 3PLs will be working with a number of retailers, which means they can often negotiate discounted shipping and courier rates due to the sheer volume of orders they’re processing.

- Lower upfront costs: Since you’re saving costs on warehouse space and staff, you can put this money towards finding a good 3PL provider.

Cons

- Lack of control: You have less choice when it comes to exactly how your orders are delivered. For example, your chosen 3PL supplier may have their own fleet of delivery vehicles or they may have a good deal with a bigger carrier. You could negotiate exactly who you want to have delivering your orders, while still utilizing third party warehouse and fulfillment expertise, but you may end up paying a premium for it.

- Quality risks: Your 3PL owns and controls the final handoff of value to your customers; heavily impacting your customer satisfaction levels one way or another. Be sure to do your due diligence and choose a trusted provider.

Amazon Logistics

Amazon are now offering their own version of 3PL – dispatch your inventory to Amazon Logistics and your orders will be dispatched using Amazon’s own fleet of, mostly contractor-based, delivery vehicles.

One of the biggest pulls of outsourcing your fulfillment to Amazon Logistics is the refreshing speed at which Amazon can get your orders to your customers, such as Same Day delivery.

If you are using omnichannel inventory management software, such as Brightpearl, you can manage directly FBA in Brightpearl.

You will also need to hold adequate business insurance and keep your customer service game on point. These are requirements put in place by Amazon Logistics directly. Ensuring sellers provide the best possible customer service is a focus for Amazon, and not checking all the boxes may result in your removal from Amazon Logistics as a seller.

3. Dropshipping

Dropshipping fulfillment involves forwarding orders and shipments as a request to a vendor or manufacturer. They will then be responsible for sending the items to your customers on your behalf, usually with your branding, so the customer is unaware you’ve even used a dropshipping company.

As a drop-shipper, you will enter an agreement with one or more wholesalers to have products sent directly to your customers as orders are placed.

This removes a number of risks from your business as you do not hold products and do not need to keep such a close eye on your inventory levels. However, you may pay more for your products than you would in a typical wholesale agreement.

Pros

- Lowest overheads: You won’t need to store any physical products, maintain a dispatch process and team, or even pay for inventory up-front. This money can be used to grow other areas of your business.

- Reduces risk: As you don’t hold inventory yourself, you won’t need to constantly monitor inventory levels, or worry about inventory theft or overselling — that’s your dropshipper’s responsibility.

- Freedom: Due to not buying or storing inventory yourself, there’s less risk in testing new products with your customers to see how they perform. This offers freedom to try new things and potentially increase revenue if the new items perform well.

- Accessibility: Once you’ve found some dropshipping companies to work with, you can easily get set up with them, making this route to market completely accessible.

- Scalability: Usually, if your sales double, you and your team do double the work. But in a dropshipping business, it’s your suppliers that are bearing the brunt of increased volumes and order processing, meaning there’s no hindrance to growing as a business.

Cons

- Lower margins: Suppliers will often charge a premium to use your branding on their packages, meaning your margins may have to take a hit at first. That is, until you build a loyal customer audience who won’t mind paying more for their items.

- Customer satisfaction: Liaising with your suppliers to handle customer service issues is not only a lot of extra work for you and your team, but can also cause further customer dissatisfaction.

- Varied costs: When working with a number of suppliers, it can be difficult to keep on top of how much each company is charging you, and thus, how much you should charge your customers.

4. Hybrid system

As with many things, a single order fulfillment solution may not always be the best one. Any company may choose a hybrid option (one that combines two or more of the options above), because it fits better with the type of products they sell or their target audience. This model works well where there is a diverse supply chain.

For example, a US furniture company only sells its products online. They find that much of their demand comes from within a 50 mile radius of their base. But around 25% of demand is from further afield across mainland USA. They choose to keep local order fulfillment in house, but outsource national fulfillment to a 3PL. They may also sell curtains or accessories alongside their main product lines. These items they could choose to dropship for greater efficiency in fulfillment.

How retailers can optimize their order fulfillment process

Any online retailer wants their workflow and order fulfillment process to be operating at optimum levels, at all times. Just as technology plays a major role in your sales and marketing, so it does with the order fulfillment side of your business.

Knowing which technology to use, either as singular systems, part of an all-in-one platform, or even in partnership with your fulfillment provider, can help optimize the entire process. Here are some examples of tech solutions to consider:

- Order management system (OMS). It doesn’t matter whether your model is B2B or B2C, a suitable OMS helps your company speed up order processing and reduce mistakes in both the areas of fulfillment and purchase. It usually comes with inventory management features that update multiple sales channels with the right inventory levels.

- Inventory management system (IMS). Keeping track of stock via inventory and warehouse management systems is fundamental to e-commerce success. You will also want software that can integrate and share information readily with any 3PL providers.

- Electronic data exchange (EDI). When you are working in partnership with an order fulfillment provider, there will be a lot of electronic data needing to get transferred between you. The best way of doing this is via an EDI system. It can keep track of all relevant data so both relevant parties have access to it. Your fulfillment center will likely have an end to end EDI in place.

- Purchasing and supplier management. A good purchasing and supplier management system can improve your replenishment process, help you reorder at the right time, and choose the most suitable supplier. This ensures you have the right amount of goods to meet customer demand.

- POS. For physical store retailers, having a POS system that can be connected to e-commerce channels is handy. This allows you to have up-to-date inventory and sales order information across both online and offline channels.

- Shipping. If you are carrying out fulfillment in house, you want to choose the optimum shipping solutions. In some cases, this may mean cheapest and in others, quickest. Using a good logic based system helps identify the best shipping costs and solutions for your needs.

- Analytics and reporting. If you get things just right from the start, then you are extremely lucky. Most processes and systems need tweaking and adjusting over time. Using good analytics and reporting programs can help you identify both good and bad factors in your workflow.

- All-in-1 retail-tailored Digital Operations Platform: an intelligent retail system like Brightpearl will have all the core functionality in one place. It allows you to speed up your order fulfillment process by automating all the time-consuming tasks. It also updates automatically your multichannel inventory levels and accounting data as soon as items are shipped out of the door.

The takeaway

How you fulfill orders is as important for your business as how you market, sell, and communicate with your customers. Perhaps even more so. In an increasingly competitive world, customers have more choice than ever before, and if they think a business has weaknesses in the fulfillment process, they will simply choose another vendor.

As an e-commerce organization, your end goal is high customer satisfaction levels. These drive customer loyalty and retention, as well as attracting new customers to your business. This in turn leads to increased sales, revenue, and profitability—in short, a healthier bottom line. Your order fulfillment process is crucial in reaching the desired levels of satisfaction to achieve all those knock-on benefits.